N-substituted acrylamide monomer and preparation method thereof, and acrylamide copolymer and preparation method thereof

A technology of acrylamide copolymer and acrylamide monomer, which is applied to acrylamide copolymer and its preparation, and its preparation, in the field of N-substituted acrylamide monomer, can solve the problem that the temperature resistance and salt resistance of polyacrylamide is difficult to meet high temperature and high temperature. Problems such as the requirements for the use of salt reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a kind of preparation method of N-substituted acrylamide monomer, comprises the following steps:

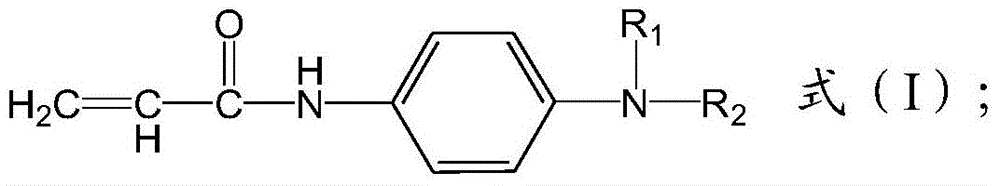

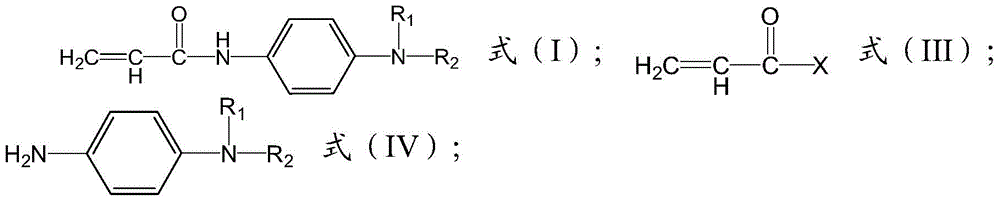

[0043] The compound of formula (III) is reacted with the compound of formula (IV) to obtain the N-substituted acrylamide monomer having the structure of formula (I);

[0044]

[0045] Among them, R 1 and R 2 are independently selected from alkyl groups; X is halogen.

[0046]In the preparation method provided by the present invention, the N-substituted acrylamide monomer with the structure of the formula (I) can be obtained by directly reacting the compound of the formula (III) and the compound of the formula (IV), and the process is specifically as follows:

[0047] The structural compound of formula (III) and the structural compound of formula (IV) are mixed and reacted in a solvent. Wherein, the structure of the compound of formula (III) is as follows:

[0048]

[0049] In formula (III), X is halogen, preferably Cl, Br or I.

[...

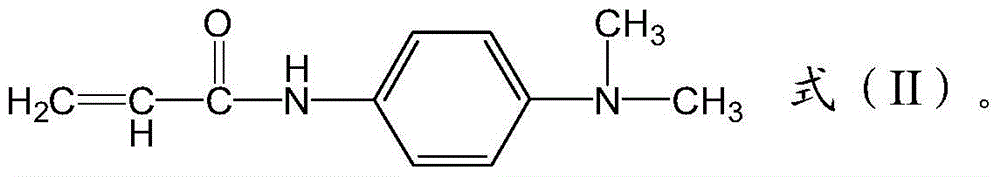

Embodiment 1

[0098] Preparation of N-alkylacrylamide monomers

[0099] Step 1: Preparation of Acryloyl Chloride

[0100] In a four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure dropping funnel, first add thionyl chloride according to n (acrylic acid): n (thionyl chloride): = 1:1.5, and add a small amount of Polymerization inhibitor hydroquinone, control the system temperature at -5 ~ 5 ° C, slowly add acrylic acid dropwise under stirring conditions, after the dropwise addition, the system is slowly heated to 55 ° C, the reaction appears to reflux, and use sodium hydroxide aqueous solution as the acidic Gas absorption liquid, constant temperature reaction for 3 hours, after the end, the system was slowly cooled to room temperature; the device was changed to vacuum distillation, and a colorless irritating liquid was collected, and the colorless irritating liquid was detected by nuclear magnetic resonance, and its hydrogen spectrum detection re...

Embodiment 2

[0106] Preparation of N-alkylacrylamide monomers

[0107]In a four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen protection device, follow n(N,N-dimethyl-p-phenylenediamine): n(dimethylformamide DMF )=1:2, add 102.5g N,N-dimethyl-p-phenylenediamine and 110.03gDMF, then add 15.0g sodium carbonate powder (as an acid-binding agent, react with HCl, one of the products, to promote the forward reaction), Under stirring conditions, the temperature of the system is controlled by an ice-water bath at -5 to 5°C, according to n(N,N-dimethyl-p-phenylenediamine):n(acryloyl chloride)=1:1.5, using a constant pressure dropping funnel to slowly Add dropwise the acryloyl chloride solution composed of 102.21g of the acryloyl chloride liquid prepared in Example 1 and 82.56g of DMF solvent. The molar ratio of the two is 1:1. A crude yellowish N-substituted acrylamide is obtained. The crude product was first washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com