Alkali-corrosion-resistant organic magnetic material and preparation method thereof

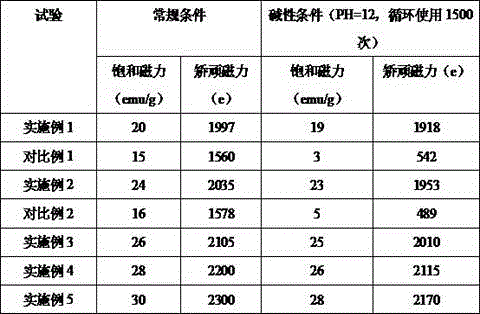

A magnetic material and organic technology, applied in the field of alkali-resistant corrosion organic magnetic materials and their preparation, to achieve the effect of improving corrosion resistance and magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Mix 15 parts of acetyl ferrocene, 3 parts of ferrous lactate, 5 parts of copper 2,3-dihydroxysuccinate, 2 parts of copper sodium edetate, 10 parts of ABS resin and 2 parts of iron stearate Pour into a reactor fed with nitrogen, raise the temperature to 100°C at a rate of 2°C / min, and stir rapidly at a rate of 200r / min for 10min after the temperature reaches, to obtain solution A;

[0017] (2) Add 9 parts of 4-cyclohexyl resin, 12 parts of polyimide resin, 10 parts of 2,4-octanedial, 5 parts of 1-(2-pyridylazo)-2-naphthol, phthalic acid Add 4 parts of dinonyl ester and 6 parts of ethyl 9-fluorenylidene acetate into the reactor, rapidly raise the temperature to 130°C, and react for 20 minutes to obtain solution B;

[0018] (3) Add 6 parts of 2-acetylthiophene vinyl acetal to solution B and solution A, and use microwave heating method to heat for 5 minutes at a power of 3000W; then cool to obtain the alkali corrosion-resistant organic magnetic material.

Embodiment 2

[0024] (1) Mix 25 parts of acetyl ferrocene, 10 parts of ferrous lactate, 10 parts of copper 2,3-dihydroxysuccinate, 6 parts of sodium copper edetate, 13 parts of ABS resin and 5 parts of iron stearate Partially added to the reactor fed with nitrogen, the temperature was raised to 120°C at a rate of 5°C / min, and after the temperature reached, it was stirred rapidly at a rate of 400r / min for 15min to obtain solution A;

[0025] (2) Mix 15 parts of 4-cyclohexyl resin, 16 parts of polyimide resin, 20 parts of 2,4-octanedial, 9 parts of 1-(2-pyridylazo)-2-naphthol, phthalic acid Add 8 parts of dinonyl ester and 12 parts of ethyl 9-fluorenylidene acetate into the reactor, rapidly raise the temperature to 150°C, and react for 30 minutes to obtain solution B;

[0026] (3) Add 10 parts of 2-acetylthiophene ethylene acetal into solution B and solution A, and heat for 8 minutes at a power of 5000 W by using microwave heating method; then, after cooling, the alkali corrosion-resistant or...

Embodiment 3

[0032] (1) Mix 18 parts of acetyl ferrocene, 5 parts of ferrous lactate, 7 parts of copper 2,3-dihydroxysuccinate, 3 parts of copper sodium edetate, 11 parts of ABS resin and 3 parts of iron stearate Pour into a reactor fed with nitrogen, raise the temperature to 100°C at a rate of 2°C / min, and stir rapidly at a rate of 200r / min for 10min after the temperature reaches, to obtain solution A;

[0033] (2) Add 9 parts of 4-cyclohexyl resin, 12 parts of polyimide resin, 10 parts of 2,4-octanedial, 5 parts of 1-(2-pyridylazo)-2-naphthol, phthalic acid Add 4 parts of dinonyl ester and 6 parts of ethyl 9-fluorenylidene acetate into the reactor, rapidly raise the temperature to 130°C, and react for 20 minutes to obtain solution B;

[0034] (3) Add 7 parts of 2-acetylthiophene vinyl acetal to solution B and solution A, and use microwave heating method to heat for 5 minutes at a power of 3000W; then cool to obtain the alkali corrosion-resistant organic magnetic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com