Methanol gasoline additive

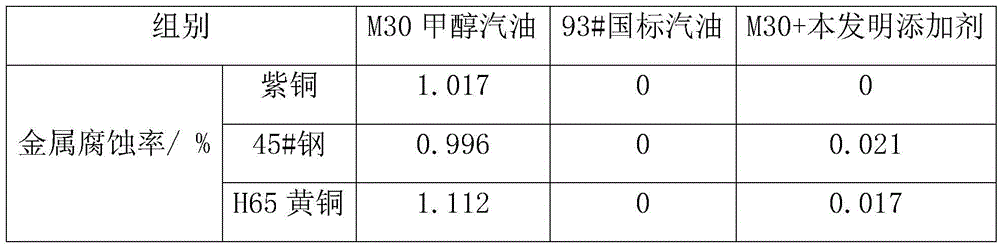

A methanol gasoline and additive technology, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as corrosion, improve combustion efficiency, reduce automobile metal corrosion, and enhance power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A. 25 kg of isoamyl alcohol, 14 kg of propylene glycol methyl ether, 9 kg of propylene glycol monomethyl ether acetate, 5 kg of tert-butyl methyl ether, 4 kg of isooctyl phosphate (RP-98), 4 kg of octylphenol polyoxygen Vinyl ether (OP-7) 4 kilograms, hexaethylene glycol monodecyl ether 7 kilograms, add in the reaction kettle successively, stir evenly with magnetic machine;

[0014] B. Add 5 kg of benzotriazole and 7 kg of triethylene glycol monobutyl ether into the mixture in step A, stir evenly with a magnetic machine, heat to 50° C. for 1 to 2 hours, and cool. The methanol gasoline additive of the present invention is suitable for M15-M30 methanol gasoline, and the addition amount in M15-M30 methanol gasoline is preferably 400-500 mg / L.

Embodiment 2

[0016] A. 22 kg of isoamyl alcohol, 12 kg of propylene glycol methyl ether, 8 kg of propylene glycol monomethyl ether acetate, 4 kg of tert-butyl methyl ether, 3 kg of isooctyl phosphate (RP-98), 3 kg of octylphenol polyoxygen 3 kilograms of vinyl ether (OP-7) and 6 kilograms of hexaethylene glycol monodecyl ether were added to the reaction kettle in turn, and stirred evenly with a magnetic machine;

[0017] B. Add 4 kg of benzotriazole and 6 kg of triethylene glycol monobutyl ether into the mixture in step A, stir evenly with a magnetic machine, heat to 50° C. for 1 to 2 hours, and cool. The methanol gasoline additive of the present invention is suitable for M15-M30 methanol gasoline, and the addition amount in M15-M30 methanol gasoline is preferably 400-500 mg / L.

Embodiment 3

[0019] A, 28 kilograms of isoamyl alcohol, 15 kilograms of propylene glycol methyl ether, 10 kilograms of propylene glycol monomethyl ether acetate, 6 kilograms of tert-butyl methyl ether, 5 kilograms of isooctyl phosphate (RP-98), octylphenol polyoxygen 5 kilograms of vinyl ether (OP-7) and 8 kilograms of hexaethylene glycol monodecyl ether were added to the reaction kettle in turn, and stirred evenly with a magnetic machine;

[0020] B. Add 6 kg of benzotriazole and 8 kg of triethylene glycol monobutyl ether into the mixture in step A, stir evenly with a magnetic machine, heat to 50° C. for 1 to 2 hours, and cool. The methanol gasoline additive of the present invention is suitable for M15-M30 methanol gasoline, and the addition amount in M15-M30 methanol gasoline is preferably 400-500 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com