Dilution treatment method for copper smelting slag

A technology of copper smelting slag and treatment method, which is applied in the field of metallurgy, can solve the problems of serious volatilization, serious environmental pollution, and low utilization rate, and achieve the effects of reducing copper content, reducing environmental pollution, and improving kinetic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

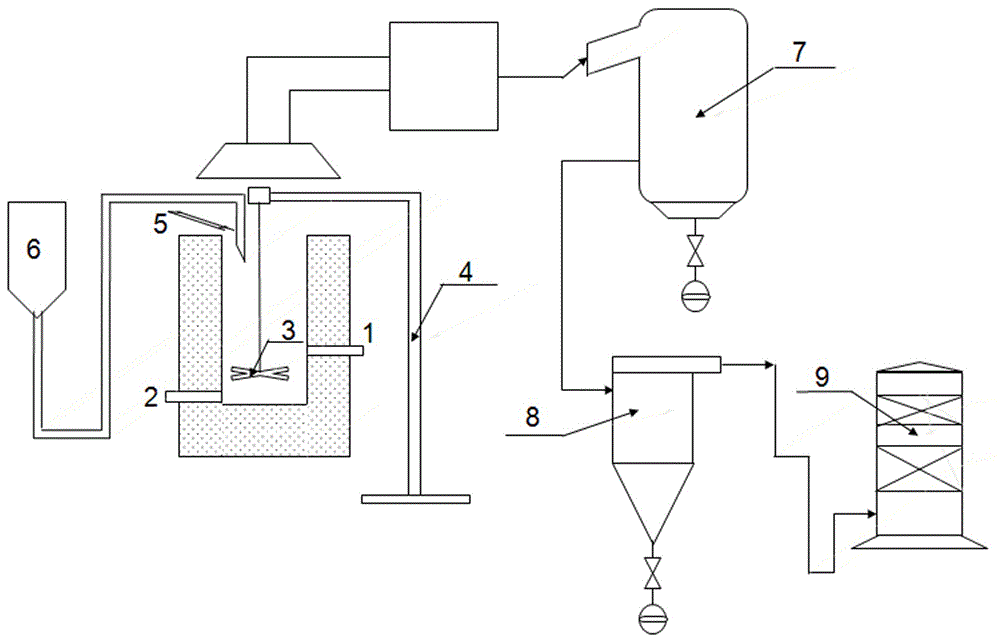

[0032] The amount of molten copper smelting slag is 20t, the composition is shown in Table 1, and the depletion furnace used is as follows figure 1 As shown, the depletion treatment method is carried out according to the following process steps:

[0033] (1) Introduce mechanical stirring equipment into the depletion furnace, introduce high-temperature molten copper smelting slag at 1150~1350 °C, adjust the stirring blade to extend to 1 / 3 of the liquid level of copper smelting slag, start heating and stirring, Control the temperature of copper smelting slag to 1250°C, the stirring speed to 50r / min, and form a vortex with a ratio of diameter to height of 3;

[0034] (2) Blow 600kg of copper concentrate and 400kg of calcium oxide from the nozzle above the high-temperature molten copper smelting slag liquid surface to the surface of the copper smelting slag pool near the center of the vortex, and keep stirring for 40 minutes;

[0035] (3) Static stratification, respectively colle...

Embodiment 2

[0038] The amount of molten copper smelting slag is 22t, and the composition is shown in Table 1. The depletion furnace used is as follows figure 1 As shown, the depletion treatment method is carried out according to the following process steps:

[0039] (1) Introduce mechanical stirring equipment into the depletion furnace, introduce high-temperature molten copper smelting slag at 1150~1350 °C, adjust the stirring blade to extend to 1 / 2 of the liquid level of copper smelting slag, start heating and stirring, Control the temperature of the copper smelting slag to 1280°C, the stirring speed to 200r / min, and form a vortex with a diameter-to-height ratio of 0.5;

[0040] (2) Blow 660kg of pyrite and 440kg of calcium oxide from the nozzle above the liquid surface of the high-temperature molten copper smelting slag to the surface of the copper smelting slag pool near the center of the vortex, and keep stirring for 60 minutes;

[0041] (3) Static layering, respectively collecting t...

Embodiment 3

[0044] The amount of molten copper smelting slag is 1 ton, and the composition is shown in Table 2. The depletion furnace used is as follows figure 1 As shown, the depletion treatment method is carried out according to the following process steps:

[0045] (1) Introduce mechanical stirring equipment into the depletion furnace, introduce high-temperature molten copper smelting slag at 1150~1350 °C, adjust the stirring blade to extend to 1 / 2 of the liquid level of copper smelting slag, start heating and stirring, Control the temperature of copper smelting slag to 1260°C, the stirring speed to 80r / min, and form a vortex with a ratio of diameter to height of 2;

[0046] (2) Blow 17kg of pyrite and 15kg of calcium oxide from the nozzle above the high-temperature molten copper smelting slag liquid surface to the surface of the copper smelting slag pool near the center of the vortex, and keep stirring for 30 minutes;

[0047] (3) Static layering, respectively collecting the lower laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com