Depth transducer automatic calibration system and calibration method

A depth sensor and automatic calibration technology, applied in testing/calibration devices, instruments, measuring devices, etc., can solve problems such as affecting the efficiency of depth calibration, consuming manpower and time, and errors in manual readings, saving manpower and reducing human effort. Error, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

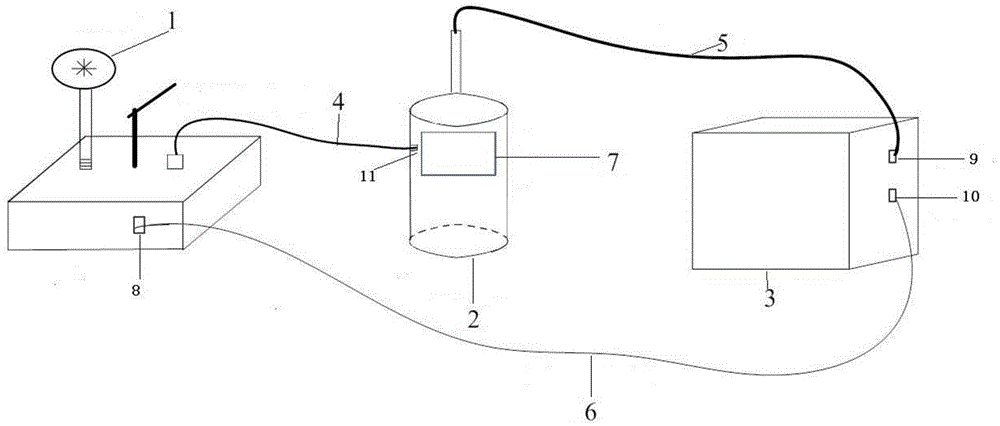

[0023] The following examples are combined with figure 1 and figure 2 The present invention is described further:

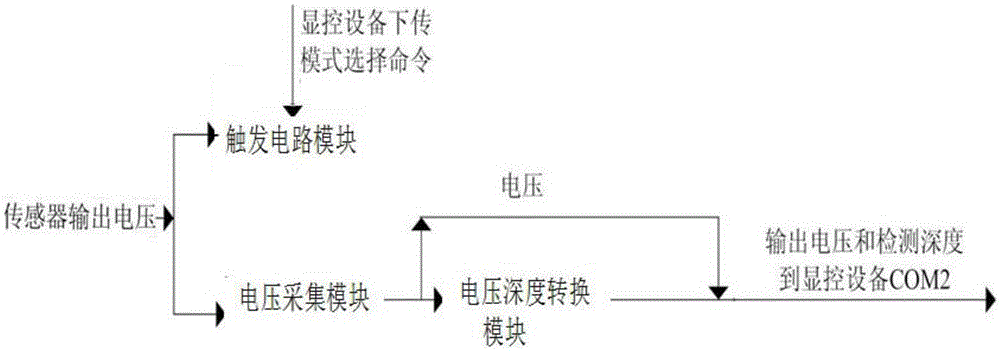

[0024] To realize automatic depth calibration, there are two key issues to be solved: one is to collect data synchronously with the output pressure of the pressure gauge (1) and the output voltage of the depth detection single-chip microcomputer, so as to improve the work efficiency of depth calibration; (1) When pressing, there is a process of air pressure stabilization. If it is changed to automatic calibration, the program needs to judge the stable state of the pressure gauge (1) and generate a trigger signal for data collection.

[0025] like figure 1 As shown, the air pressure output line 4 of the pressure gauge 1 is connected to the depth sensor 11 in the watertight electronic cabin 2, and the serial port I (1-1) 8 of the pressure gauge 1 is connected to the serial port I9 of the display control system computer 3 through the pressure data line 6 , the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com