A Multi-valued Storage Unit Based on Co-control of Conductive Filament and Polarization

A technology of multi-value storage and conductive wire, which is applied in the field of information technology storage, can solve the problems of low storage density and Si process incompatibility, and achieve the effect of enhancing conductivity, reducing resistance and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

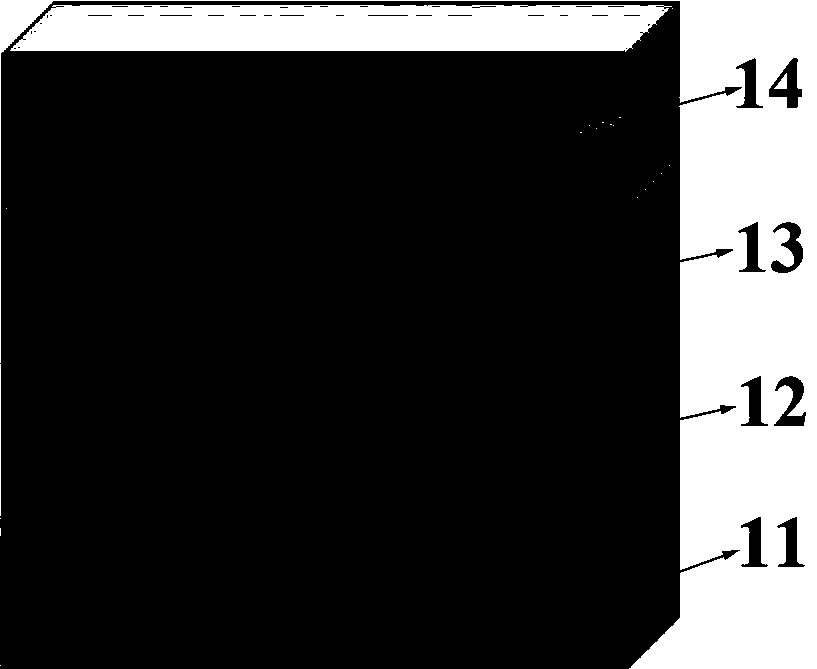

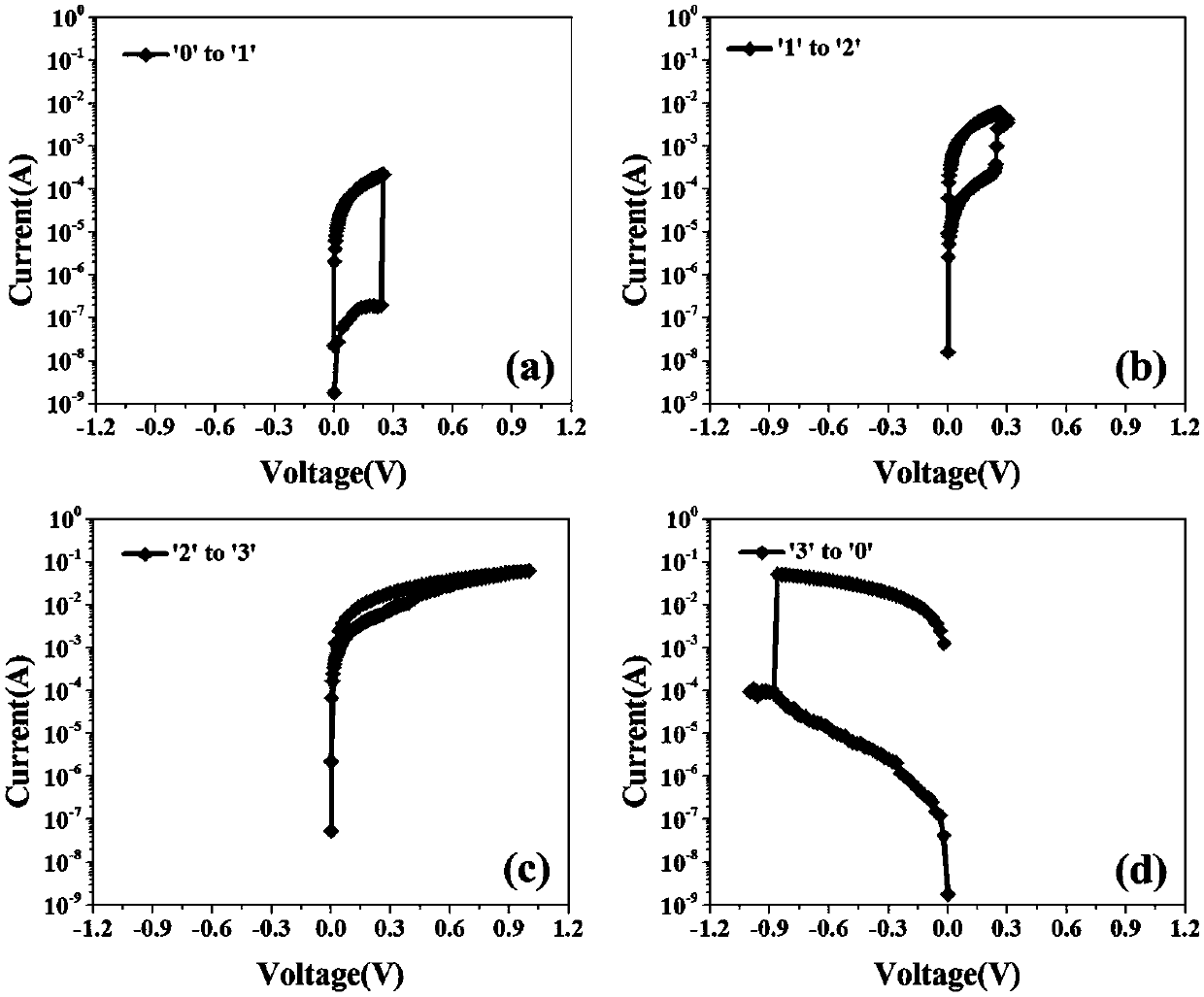

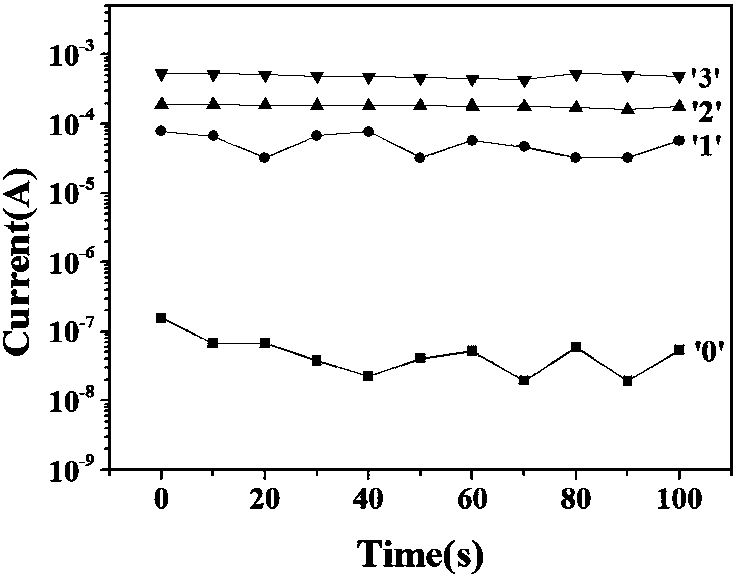

[0018] The prepared Ag / ZnO(2%Mn doped) / Pb(Zr 0.52 Ti 0.48 )O 3 / Pt A multi-valued storage unit based on conductive filament and polarization co-control includes the following steps:

[0019] (1) Preparation of Pt top electrode substrate

[0020] The Si substrate coated with the Pt bottom electrode was cleaned and dried.

[0021] (2) Pb(Zr 0.52 Ti 0.48 )O 3 Ferroelectric thin film

[0022] In a vacuum chamber, the Pb(Zr 0.52 Ti 0.48 )O 3 The target is installed on the target rack, and the mechanical pump and the molecular pump are turned on in turn to vacuumize. Wait until the pressure in the vacuum chamber reaches 1×10 -6 At about mTorr, place the cleaned Pt substrate on the substrate holder, and adjust the distance between the substrate and the target to be 60 mm. Evacuate the pressure in the vacuum chamber to 3×10 -4 Pa, turn on the KrF solid-state laser (wavelength: 248 nm), adjust the laser single pulse energy to 200 mJ, and the laser repetition frequency to...

Embodiment 2

[0029] Prepared Ag / ZnO(Mn2%) / BiFeO 3 / Pt A multi-valued storage unit based on conductive filament and polarization co-control is similar to the main process in Example 1, the difference is that BiFeO 3 The preparation parameters are oxygen pressure 13Pa, deposition temperature 675°C, and the thickness is 2-5nm. In this embodiment, the storage of 4 different resistance states is realized.

Embodiment 3

[0031] Prepared Ag / ZnO(Mn2%) / BaTiO 3 / Pt A multi-valued storage unit based on conductive filament and polarization co-control is similar to the main process in Example 1, the difference is that BaTiO 3 The preparation parameters are oxygen pressure 2.6Pa, deposition temperature 675°C, and the thickness is 2-5nm. In this embodiment, the storage of 2-10 different resistance states is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com