A grease composition for improving the glossiness and oily feel of baked goods

An oil composition and oil technology, applied in the direction of edible oil/fat, edible oil/fat component, edible oil/fat containing fatty acid ester, etc., can solve the problem of not being able to replace oil, increasing the complexity of the operation process, and being unable to improve baking Problems such as the internal gloss of the product can be solved to achieve the effect of improving product quality and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

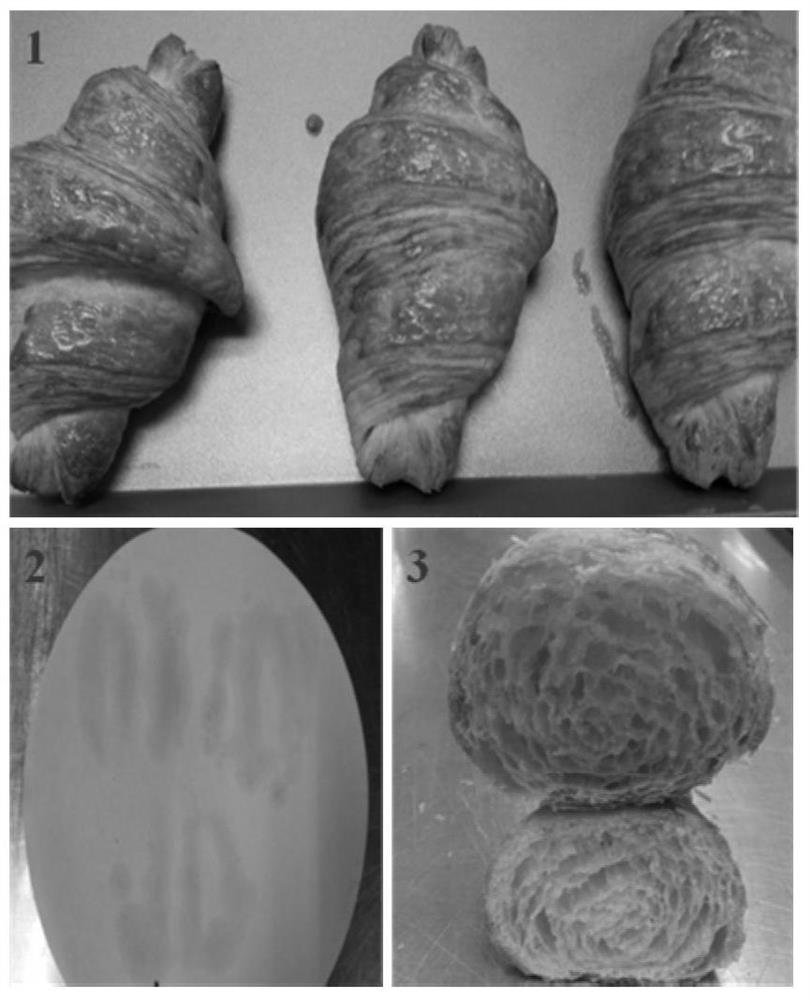

[0105] Danish croissants were made with the margarine prepared from the oil composition of the present invention, and the oiliness and glossiness were evaluated.

[0106] 1.1 Prepare margarine samples as follows:

[0107] According to the formulation of the oil composition of each embodiment and comparative example shown in Table 1, the oil phase is put into an emulsification tank, heated to 60 ° C for melting, emulsifier and pigment are dissolved therein, salt and citric acid have been added The water phase heated to a certain temperature (about 40-50°C) is added to the oil phase, stirred and emulsified for 30 minutes, quenched, kneaded, and passed through a resting tube to obtain a sheet-shaped sample, which is aged at 10°C for 7 days to obtain a sheet-shaped artificial Creamy finished product.

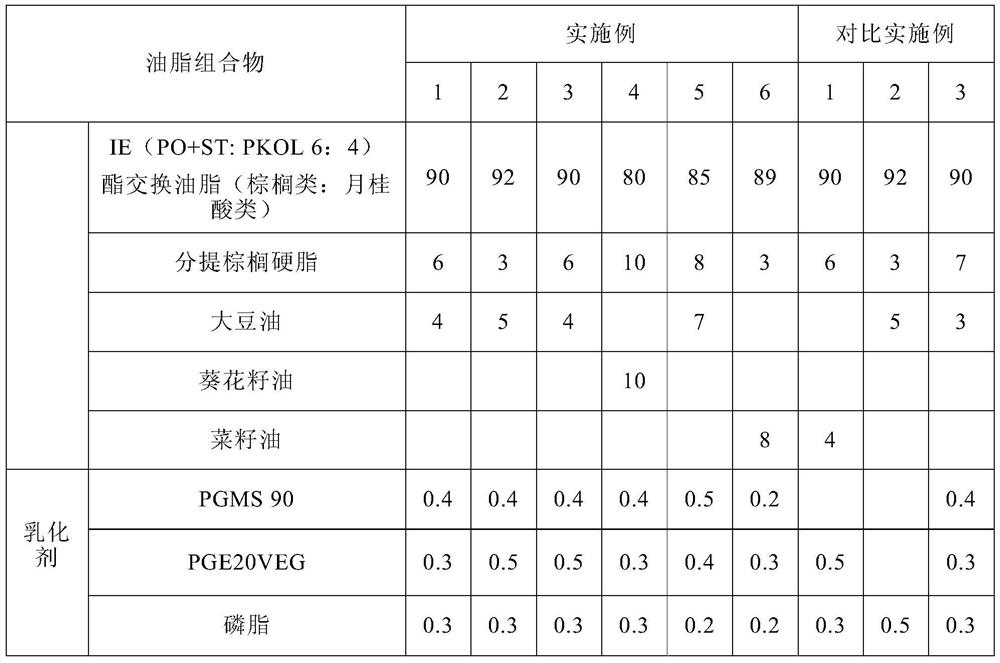

[0108] Table 1: Lipid Composition Formulation

[0109]

[0110]

[0111] 1.2 The flaky margarine products obtained in Examples and Comparative Examples are used to make croiss...

Embodiment 2

[0129] Prepare puff pastry (flaky margarine) samples as follows:

[0130] According to the formulation of the oil composition of each embodiment and comparative example shown in Table 5, the oil phase is put into an emulsification tank, heated to 60 ° C for melting, emulsifier and pigment (β-carotene) are dissolved therein, and Add salt and citric acid to the water phase heated to a certain temperature (40-50°C), add to the oil phase, stir and emulsify for 30 minutes, quench, knead, and pass through the stop tube to obtain a sheet-like sample, aging at 10°C for 7 days , to obtain a flaky margarine finished product.

[0131] Table 5: Oil composition formula

[0132]

[0133]

[0134] Remarks: monoglyceride acetate and mono / diglyceride fatty acid esters have the same HLB value of 2.8.

[0135] The flaky margarine product that obtains with embodiment and comparative example makes croissant according to croissant conventional recipe (recipe is shown in Table 6), and prepar...

Embodiment 3

[0153] Danish croissants were made with the margarine prepared from the oil composition of the present invention, and the oiliness and glossiness were evaluated.

[0154] 3.1 Prepare margarine samples as follows:

[0155] According to the formulation of the oil composition of each embodiment and comparative example shown in Table 9, the oil phase is put into an emulsification tank, heated to 60 ° C for melting, emulsifier and pigment are dissolved therein, and salt and citric acid have been added The water phase heated to a certain temperature (about 40-50°C) is added to the oil phase, stirred and emulsified for 30 minutes, quenched, kneaded, and passed through a resting tube to obtain a sheet-shaped sample, which is aged at 10°C for 7 days to obtain a sheet-shaped artificial Creamy finished product.

[0156] Table 9: Oil composition formula

[0157]

[0158]

[0159] The flaky margarine product that obtains with embodiment and comparative example makes croissant accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com