Puffed food processing method taking pine nuts as core

A technology of puffed food and processing method, which is applied in the field of food processing, can solve the problems of high calorie, low added value and unsuitability of chocolate, and achieve the effects of short time consumption, high processing efficiency and balanced nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The puffed food processing method with pine nuts as the core of the present invention comprises the following steps: (1) frying the pine nuts and removing the shells and membranes to obtain the pine nuts; (2) making dough; (3) wrapping the pine nuts and placing the pine nuts in On the dough, the dough is curled and closed to form an open container with a cavity and an opening, and the volume of the pine nuts is smaller than the volume of the internal cavity of the dough; (4) inject jam, inject the jam from the opening of the dough, and the jam is full of the inner wall of the cavity of the dough and The gap between the pine nuts; (5) Sealing and throwing round, the opening of the dough is closed and then sent to the rounding machine for rounding; (6) Vacuum frying, under the conditions of oil temperature 100°C and vacuum degree 0.05MPa, the rounding The finished material is sent to a closed container for frying for 5-10 minutes; (7) Centrifugal deoiling, under the condit...

Embodiment 2-6

[0030] In embodiment 2-6, each step is basically the same as embodiment 1, and the parameters of frying step and deoiling step are with reference to table 1:

[0031]

Example 2 Example 3 Example 4 Example 5 Example 6 Fried Vacuum 0.65MPa 0.08MPa 0.06MPa 0.07MPa 0.05MPa frying temperature 102℃ 105℃ 103℃ 104℃ 101℃ frying time 6min 8min 9min 10min 7min Deoiling vacuum 0.08MPa 0.08MPa 0.06MPa 0.07MPa 0.05MPa

[0032] Table 1

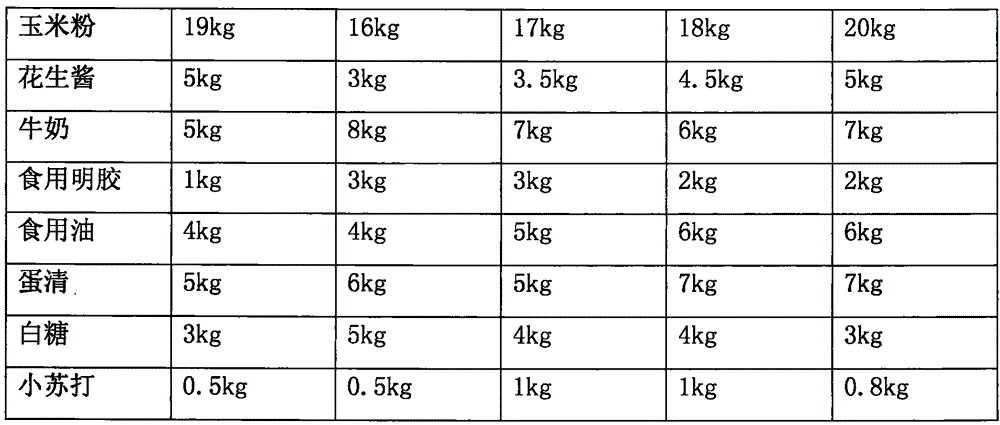

[0033] In embodiment 2-6, the distribution ratio of dough ingredients is with reference to Table 2:

[0034]

Example 2 Example 3 Example 4 Example 5 Example 6 High-gluten flour 55% 57% 58% 59% 60% Dendrobium officinale powder 8% 7% 6% 5% 8% white sugar 5% 3% 3% 3% 4% Compound Baking Powder 0.35% 0.5% 0.45% 0.3% 0.5%

[0035] Table 2

[0036] See the following table 3 for the distribution ratio of wafer shell ingre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com