Processing method of fish ball with high elasticity and enriched in laminarin

A technology of kelp polysaccharide and a processing method, which is applied in the directions of food ingredients as gelling agents, food science, etc., can solve the problems of inability to meet high elastic surimi products, surimi protein cannot be fully expanded, and affect the color and smell of products. The effect of reducing the degree of gel deterioration, novel color, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

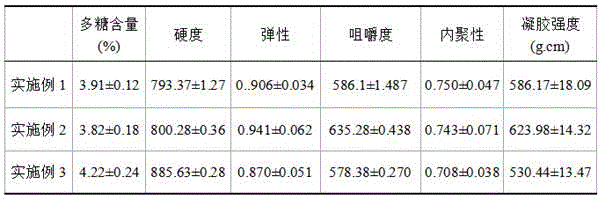

Examples

Embodiment 1

[0029] (1) Preparation of micronized kelp homogenate: take 500g of fresh kelp and wash it with water, remove the salt and dirt on the surface, put it in a tissue blender, add 500mL of distilled water, and grind it to obtain kelp homogenate, then Adjust the scale of the grinding disc, and use the colloid mill to carry out wet ultrafine pulverization of the kelp pulp, and the micronized kelp homogenate after ultrafine pulverization has a particle size of 20-35 μm.

[0030] (2) Material selection: The raw fish for the production of frozen fish balls generally requires a single fish weighing more than 0.5kg, and fish with high freshness;

[0031] (3) Pretreatment: remove the scales, abdomen, head and viscera of fresh sea fish, and wash the body and abdomen of the fish until there is no blood;

[0032] (4) Meat harvesting: use a drum-type meat harvester to harvest the sea fish pretreated in step (3), and immediately rinse the harvested fish;

[0033] (5) Rinsing: Use a neutral sal...

Embodiment 2

[0039] (1) Preparation of micronized kelp homogenate: take 500g of fresh kelp and wash it with water, remove the salt and dirt on the surface, put it in a tissue blender, add 500mL of distilled water, and grind it to obtain kelp homogenate, then Adjust the scale of the grinding disc, and use the colloid mill to carry out wet ultrafine pulverization of the kelp pulp, and the micronized kelp homogenate after ultrafine pulverization has a particle size of 30-50 μm.

[0040] (2) Material selection: The raw fish for the production of frozen fish balls generally requires a single fish weighing more than 0.5kg, and fish with high freshness;

[0041] (3) Pretreatment: remove the scales, abdomen, head and viscera of fresh sea fish, and wash the body and abdomen of the fish until there is no blood;

[0042] (4) Harvest the meat: use a drum meat harvester to harvest the sea fish after step (3) pretreatment, and rinse the fish meat immediately;

[0043] (5) Rinsing: Use a neutral salt so...

Embodiment 3

[0049] (1) Preparation of micronized kelp homogenate: take 500g of fresh kelp and wash it with water, remove the salt and dirt on the surface, put it in a tissue blender, add 500mL of distilled water, and grind it to obtain kelp homogenate, then Adjust the scale of the grinding disc, and use the colloid mill to carry out wet ultrafine pulverization of the kelp pulp, and the micronized kelp homogenate after ultrafine pulverization has a particle size of 10-20 μm.

[0050] (2) Material selection: The raw fish for the production of frozen fish balls generally requires a single fish weighing more than 0.5kg, and fish with high freshness;

[0051] (3) Pretreatment: remove the scales, abdomen, head and viscera of fresh sea fish, and wash the body and abdomen of the fish until there is no blood;

[0052] (4) Harvest the meat: use a drum meat harvester to harvest the sea fish after step (3) pretreatment, and rinse the fish meat immediately;

[0053] (5) Rinsing: use a neutral salt so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com