Pork powder prepared by using reaction spice and preparation method thereof

A technology for pork powder and spice, which is applied in the field of food processing, can solve the problems of poor flavor, unrealistic taste, loss of flavor, etc., and achieve the effects of thick taste, improved quality and rich aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

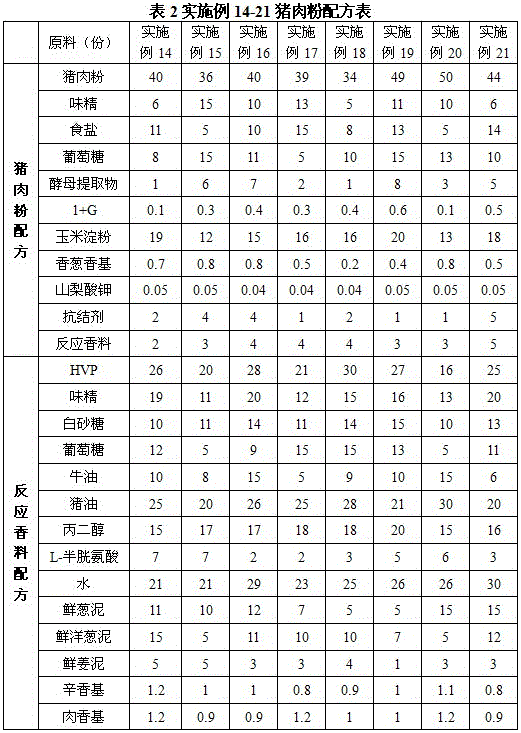

[0016] A pork powder prepared with reactive spices, which is composed of the following raw materials in parts by weight: 30-50 parts of pork powder, 5-15 parts of monosodium glutamate, 5-15 parts of table salt, 5-15 parts of glucose, and 1-8 parts of yeast extract , 0.1-0.6 parts of 1+G, 10-20 parts of corn starch, 0.1-0.8 parts of shallot base, 0.04-0.06 parts of potassium sorbate, 1-5 parts of anti-caking agent, 2-5 parts of reaction spices; The reaction flavor is composed of the following raw materials in parts by weight: 15-30 parts of HVP, 10-20 parts of monosodium glutamate, 10-15 parts of white sugar, 5-15 parts of glucose, 5-15 parts of butter, 15-30 parts of lard, 15 parts of propylene glycol -20 parts, 2-8 parts of L-cysteine, 20-30 parts of water, 5-15 parts of fresh onion puree, 5-15 parts of fresh onion puree, 1-5 parts of fresh ginger puree, 0.8-1.2 parts of spicy base , 0.8-1.2 parts of meat fragrance base; the anti-caking agent is a silicon dioxide anti-caking ...

Embodiment 2

[0025] A kind of pork powder prepared with reaction spices, which is composed of the following raw materials in parts by weight: 30 parts of pork powder, 9 parts of monosodium glutamate, 6 parts of table salt, 13 parts of glucose, 8 parts of yeast extract, 1+G0.4 parts, cornstarch 12 parts, 0.1 part of shallot fragrance base, 0.04 part of potassium sorbate, 2 parts of anticaking agent, 4 parts of reaction flavor; wherein the reaction flavor is composed of the following raw materials in parts by weight: 15 parts of HVP, 13 parts of monosodium glutamate, 13 parts of white sugar, 5 parts of glucose, 12 parts of butter, 20 parts of lard, 18 parts of propylene glycol, 2 parts of L-cysteine, 25 parts of water, 9 parts of fresh onion puree, 15 parts of fresh onion puree, 5 parts of fresh ginger puree, spicy base 1 part, 1.2 parts of meat base.

[0026] The reaction spices are prepared by Maillard reaction, and the flavor is natural and mellow. Fresh onion puree, fresh onion puree, fr...

Embodiment 3

[0034]A kind of pork powder prepared with reaction spices, which is composed of the following raw materials in parts by weight: 38 parts of pork powder, 10 parts of monosodium glutamate, 14 parts of table salt, 15 parts of glucose, 3 parts of yeast extract, 1+G0.2 parts, cornstarch 13 parts, 0.4 parts of shallot fragrance base, 0.04 parts of potassium sorbate, 2 parts of anticaking agent, 5 parts of reaction flavor; wherein the reaction flavor is composed of the following raw materials in parts by weight: 22 parts of HVP, 14 parts of monosodium glutamate, 11 parts of white sugar, 15 parts of glucose, 12 parts of butter, 22 parts of lard, 18 parts of propylene glycol, 6 parts of L-cysteine, 28 parts of water, 10 parts of fresh onion puree, 9 parts of fresh onion puree, 2 parts of fresh ginger puree, spicy base 1.1 parts, meat base 1.1 parts.

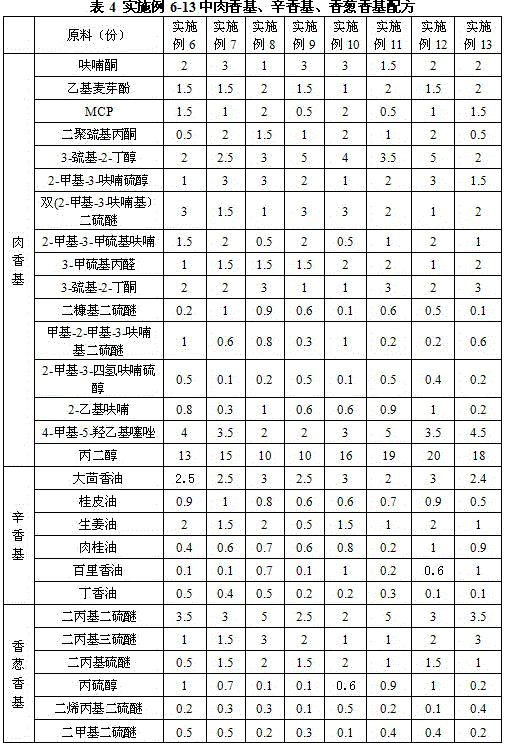

[0035] Meaty base is prepared from the following raw materials in parts by weight: 2.5 parts of furanone, 2 parts of ethyl maltol, 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com