Oil recovery system

A recovery system and oil separation technology, applied in the separation device, separation method, and dispersed particle separation, etc., can solve the problem that heavy oil and light oil cannot be directly separated, so as to reduce working hours, improve utilization efficiency, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

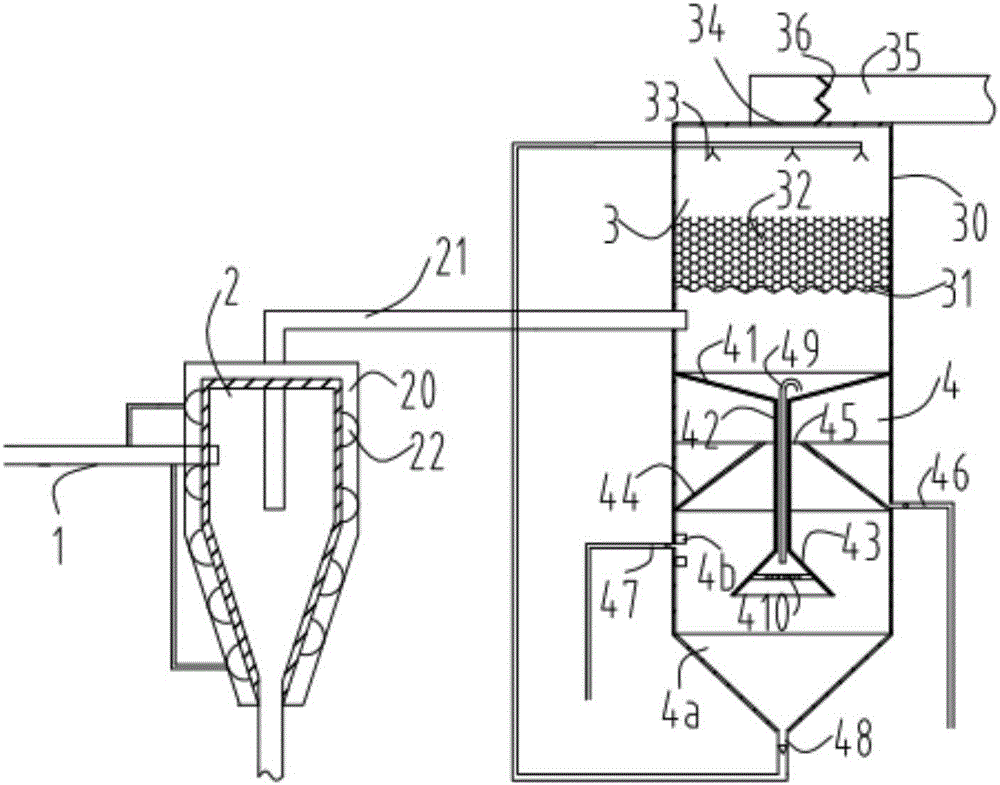

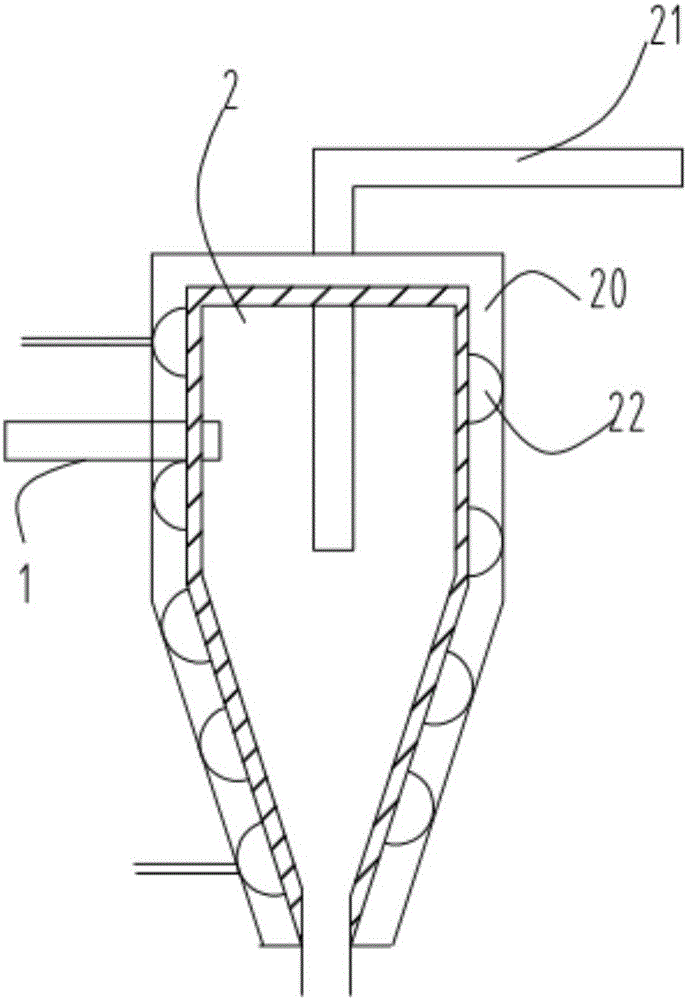

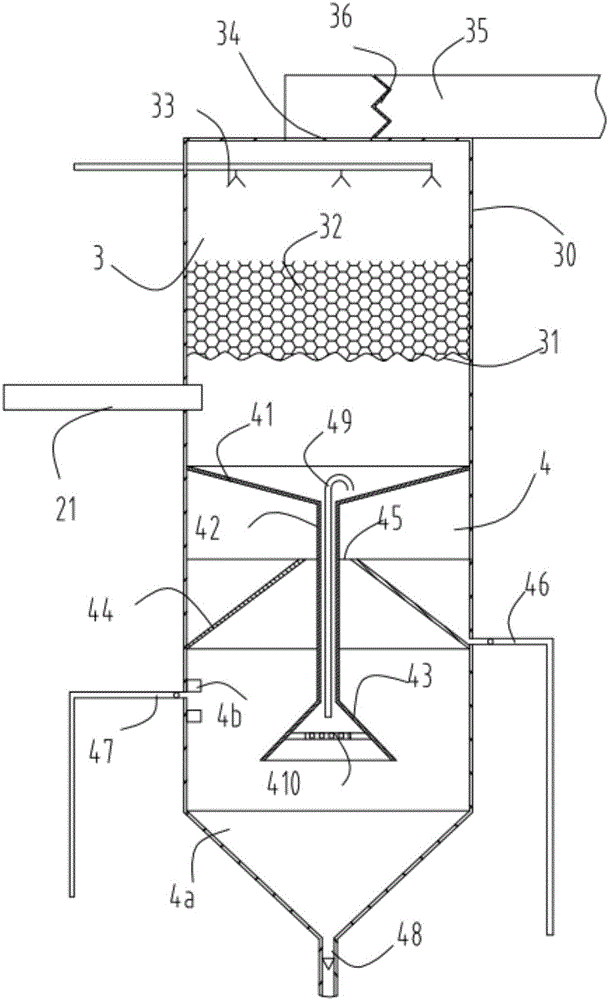

[0031] figure 1 Schematic diagram of the oil recovery system, figure 2 A schematic diagram of a cyclone dust collector, image 3 It is a schematic diagram of the spray treatment tower and the oil-water separator. like figure 1 , figure 2 and image 3As shown, what is provided in this embodiment is an oil recovery system, comprising a cyclone dust collector 2, a spray treatment tower 3 and an oil-water separator 4, the cyclone dust collector 2 is provided with a flue gas feed pipe 1, and the The cyclone dust collector 2 is connected before the spray treatment tower 3 through a gas delivery pipe 21, and the oil-water separator 4 is arranged directly below the spray treatment tower 3; the oil-water separator 4 and the spray treatment tower 3 The outer wall 30 is cylindrical and coaxially arranged, and the gas delivery pipe 21 is arranged between the spray treatment tower 3 and the oil-water separator 4; the oil-water separator 4 includes a conical inlet 41, a vertical chan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap