Hierarchical-porous zeolite preparation method

A pore zeolite and multi-level pore technology is applied in the field of preparing multi-level pore zeolite to achieve the effects of reducing the dosage, avoiding the problem of phase separation and reducing the reaction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

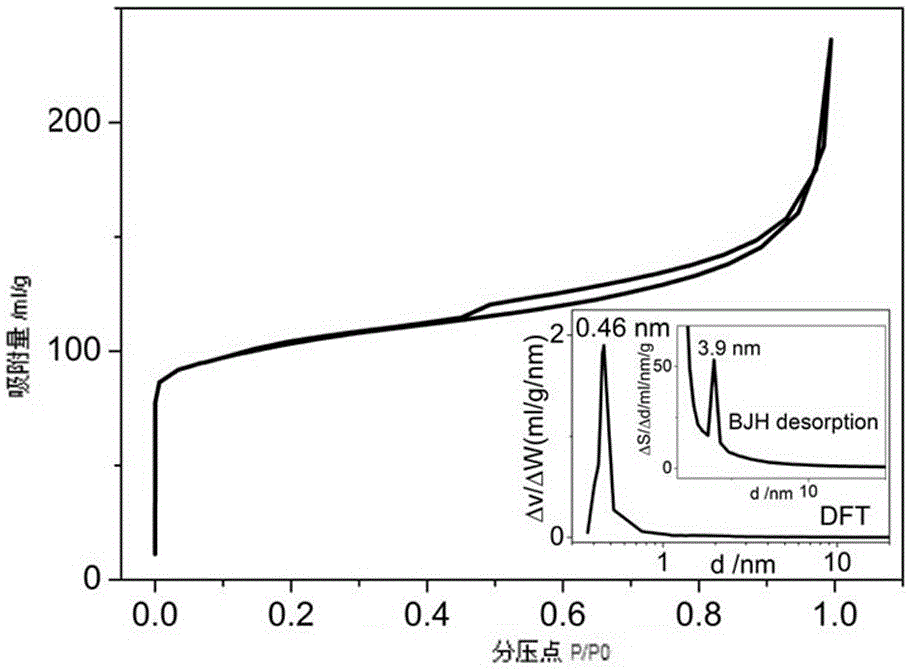

[0026] Add sodium aluminate (0.15 g), sodium hydroxide (0.54 g), CTAB (3.64 g), tetraethyl orthosilicate (17.2 ml), and deionized water (92.3 ml) in the reaction flask in sequence, at 40 °C React for 30 minutes, add 10ml MFI zeolite seed solution (TBAOH and SiO 2The molar ratio is 0.05), add in 20 minutes, and then continue to stir for 2 hours. After the reaction is completed, cool to room temperature, filter and separate the solid, and dry at 55°C. The proportion of dry powder, at 170 ℃, alkali steam treatment for 24 hours, the alkali solution is the aqueous solution of ethylenediamine (6ml ethylenediamine dissolved in 15ml water). The obtained product is washed with water, dried, and calcined at 550° C. to obtain a hierarchically porous zeolite. The molar ratio of the silicon-aluminum element of the final product obtained is Si / Al=43. The product was analyzed and characterized through pore structure, figure 1 N for the above-mentioned hierarchical pore zeolite 2 Adsorptio...

Embodiment 2

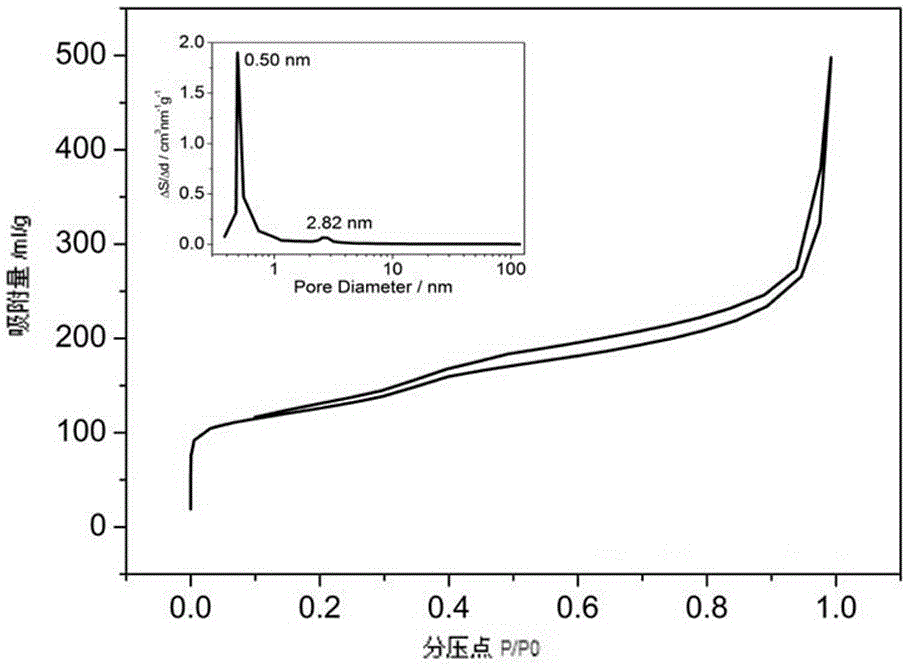

[0028] Add aluminum sulfate (0.15 g), sodium hydroxide (0.7 g), CTAB (3.64 g), white carbon black (4.6 g), and deionized water (92.3 ml) to the reaction flask in sequence, and react at 40°C for 30 minutes , add 10ml MFI zeolite seed solution (TPAOH and SiO 2 The molar ratio is 0.15), the addition was completed in 30 minutes, and then continued to stir for 2 hours. After the reaction was completed, cool to room temperature, filter and separate the solid, and dry at 55°C. The dry powder and the alkali solution corresponded to 1 The proportion of dry powder in grams, at 140 ° C, alkali steam treatment for 48 hours, the lye is an aqueous solution of ethylenediamine / triethylamine (50ml ethylenediamine, 23ml triethylamine dissolved in 10ml water). The obtained product was washed with water, dried, and calcined at 550°C to obtain a hierarchically porous zeolite. The molar ratio of the silicon-aluminum element of the obtained product is Si / Al=85; the product is analyzed and character...

Embodiment 3

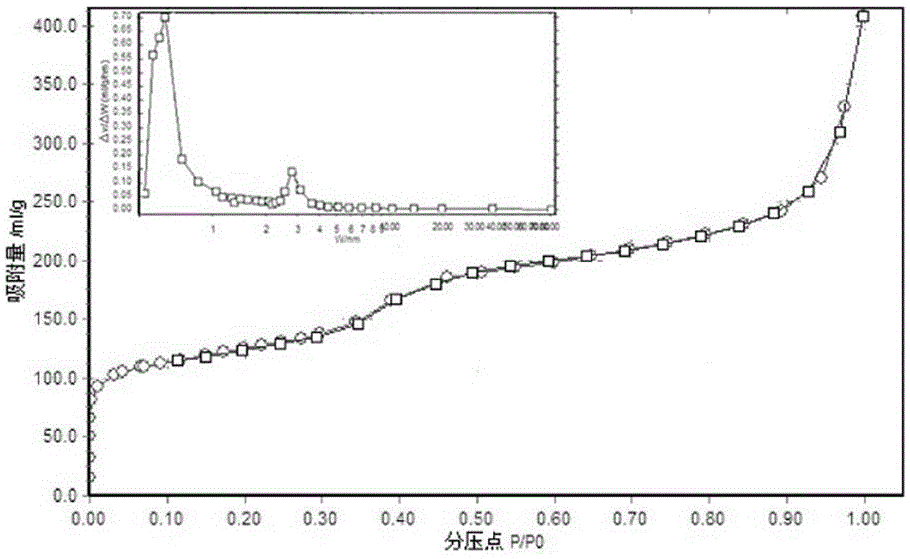

[0030] Add sodium aluminate (0.15 g), sodium hydroxide (0.7 g), P123 (2 g), tetraethyl orthosilicate (18 ml), and deionized water (92.3 ml) to the reaction flask in sequence, at 40 °C React for 30 minutes, add 10ml MFI zeolite seed solution (TBAOH and SiO 2 The molar ratio is 0.2), add in 50 minutes, and then continue to stir for 2 hours. After the reaction is completed, cool to room temperature, filter and separate the solid, and dry at 55°C. The dry powder and alkali solution correspond to 1.2ml of alkali solution The proportion of dry powder in grams, at 170°C, alkali steam treatment for 24 hours, the alkali steam is tetrabutylammonium hydroxide / ammonia mixed aqueous solution (1ml tetrabutylammonium hydroxide aqueous solution (10wt.%), 2ml concentrated ammonia solution in 10ml water). The obtained product was washed with water, dried, and calcined at 550°C to obtain a hierarchically porous zeolite. The molar ratio of silicon to aluminum in the product is Si / Al=88. The pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com