A kind of lightweight building insulation block and preparation method thereof

A building insulation and building block technology, which is applied in the field of building materials, can solve the problems of increasing energy consumption and manufacturing costs, and achieve the effects of reducing production energy consumption, simple and easy operation of equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

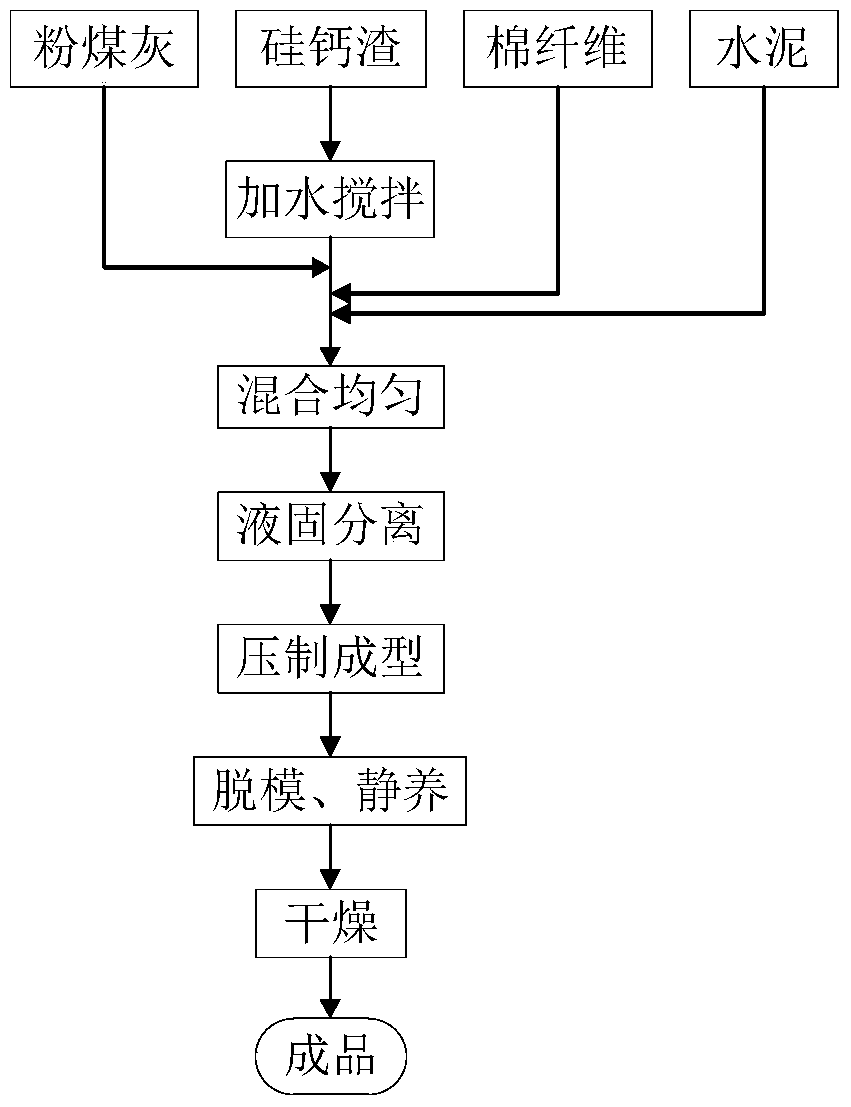

[0028] see figure 1 , The formula (mass ratio) of each component for preparing the thermal insulation block: 50wt% of calcium silicate slag, 20wt% of fly ash, 10wt% of cotton fiber, and 20wt% of cement. After accurately weighing each material, put the silicon-calcium slag in a mixer, add water and stir according to the liquid-solid ratio of 20mL / g, gradually add the weighed fly ash, cotton fiber and cement, and mix and stir at 30°C. The fibers are loosened, and the slurry is separated from the liquid to the solid after the material is evenly mixed. The filter cake is put into the mold of the molding machine and pressed, the molding pressure is 15MPa, and the molding pressure is maintained for 50min. After molding, the mold is demoulded, and the wet billet is allowed to rest for 40 hours, and then dried at 100°C. The finished product density of the insulating block made at last is 0.58g / cm 3 , the compressive strength is 6.23MPa, and the thermal conductivity is 0.15w / (m·k). ...

Embodiment 2

[0030] The formula (mass ratio) of each component for preparing the thermal insulation block: 60wt% of silicon-calcium slag, 15wt% of fly ash, 15wt% of cotton fiber, and 20wt% of cement. After accurately weighing each material, put the silicon-calcium slag in the mixer, add water and stir according to the liquid-solid ratio of 30mL / g, gradually add the weighed fly ash, cotton fiber and cement, mix and stir at 50°C, and wait for The fibers are loosened, and the slurry is separated from the liquid to the solid after the material is evenly mixed. The filter cake is put into the mold of the molding machine to be pressed, the molding pressure is 10MPa, and the molding pressure is maintained for 5min. After molding, demoulding, the wet billet rested for 20 hours, and then dried at 80°C. The finished product density of the insulating block made at last is 0.47g / cm 3 , the compressive strength is 5.03MPa, and the thermal conductivity is 0.11w / (m·k).

Embodiment 3

[0032] The formula (mass ratio) of each component for preparing the thermal insulation block: 70wt% of silicon-calcium slag, 10wt% of fly ash, 5wt% of cotton fiber, and 15wt% of cement. After accurately weighing each material, put the silicon-calcium slag in the mixer, add water and stir according to the liquid-solid ratio of 40mL / g, gradually add the weighed fly ash, cotton fiber and cement, mix and stir at 90°C, and wait for The fibers are loosened, and the slurry is separated from the liquid to the solid after the material is evenly mixed. The filter cake is put into the mold of the molding machine to be pressed, the molding pressure is 20MPa, and the molding pressure is maintained for 70min. After molding, the mold is demoulded, and the wet billet is allowed to rest for 10 hours, and then dried at 120°C. The final density of the finished insulation block is 0.36g / cm 3 , the compressive strength is 3.68MPa, and the thermal conductivity is 0.09w / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com