Large-size light guide plate with lens array and processing method thereof

A lens array and processing method technology, applied in the field of light guide plates, can solve problems such as the inability to directly produce large-size light guide plates, technical limitations of light guide plates, etc., and achieve the effect of preventing smooth forming and accurate mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

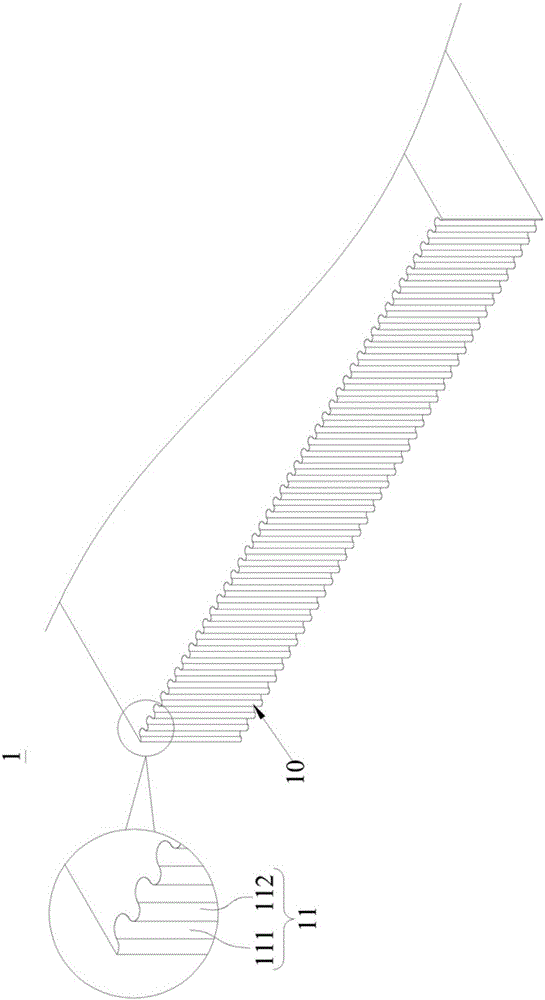

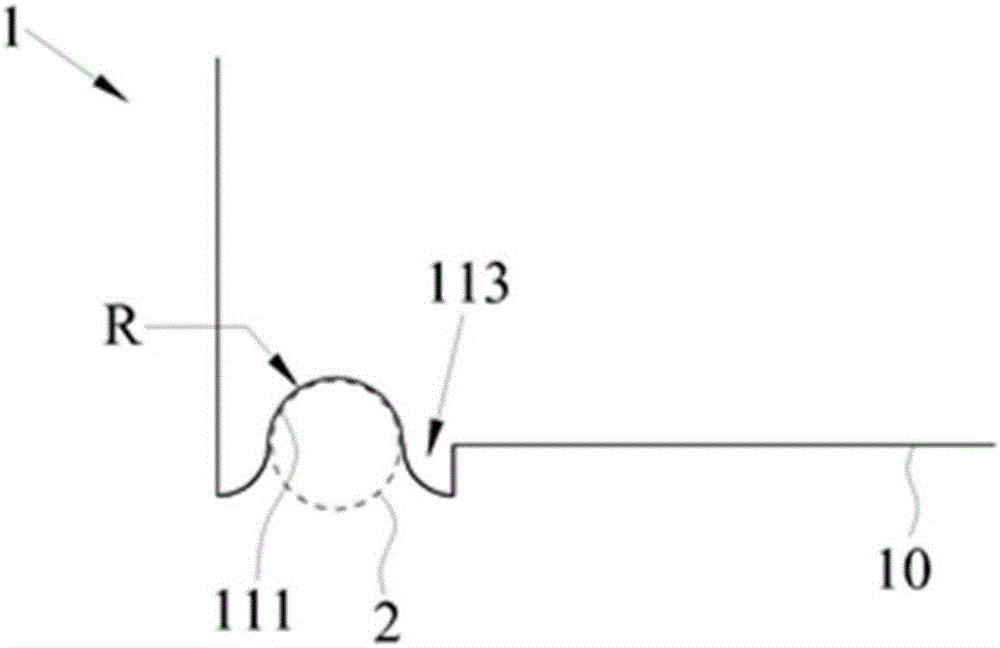

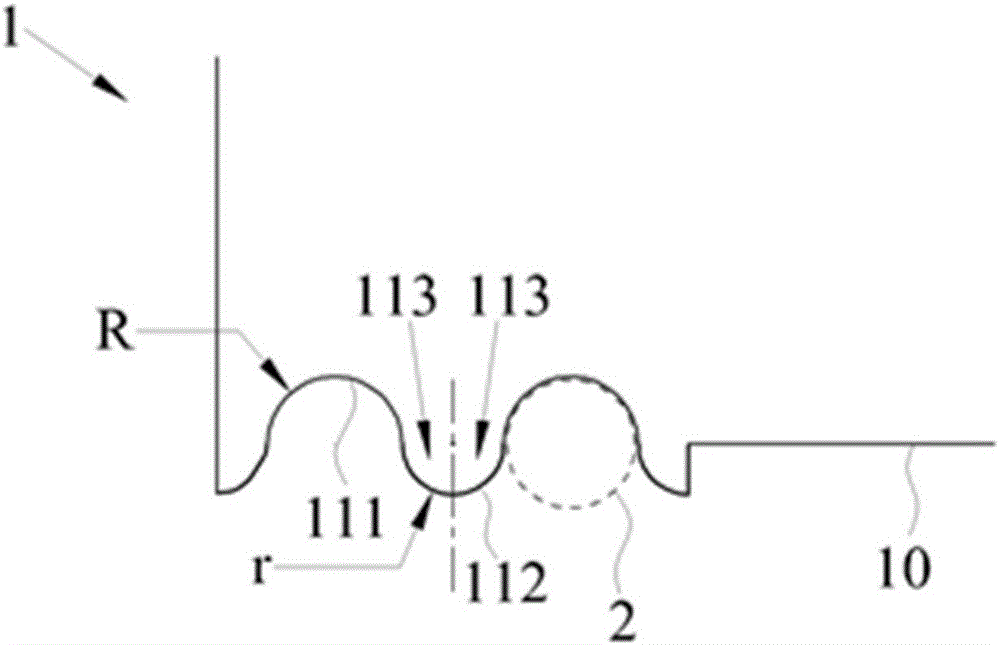

[0054] Since injection molding and tool cutting are currently used in the field of large-size light guide plates, there are many inconveniences for microstructure processing. Therefore, how to quickly mass-produce a large-sized light guide plate with a precise lens array pattern while maintaining the quality of the light guide plate is the technical feature to be revealed by the present invention. see figure 1 , figure 2 and image 3 , which is a three-dimensional structural schematic diagram and various processing schematic diagrams of Embodiment 1 of the present invention, wherein each figure is only for the convenience of explaining the technical features of the present invention. The present invention discloses a large-sized light guide plate 1 with a lens array, including a light-incident surface 10 and a lens array 11 , so that the hot spot phenomenon of the light guide plate 1 can be alleviated through the lens array 11 .

[0055] The light incident surface 10 guides ...

Embodiment 2

[0061] see Figure 4 , Figure 5 and Figure 6 , which is a flow chart of steps and a schematic diagram of each process in Embodiment 2 of the present invention. The present invention also discloses a processing method of a large-sized light guide plate with a lens array, which can quickly mass-produce a large-scale light guide plate and maintain a very high product yield rate. The processing method includes the following steps.

[0062] In step S01 , a plurality of light guide plates 1 stacked in batches are provided, and a light incident surface 10 of each light guide plate 1 is aligned with each other to form a processing plane S. Thus, a plurality of large-sized light guide plates 1 can be processed at one time, and the production rate can be improved.

[0063] Step S02 , bombard the processing plane S with a laser beam 2 to form an arc-shaped groove 111 on each incident surface 10 and generate molten material, and the bombardment condition is defined as the radius of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com