A method for removing complex nuclides 110mag and 60co/58co in radioactive water

A complex state, radioactive technology, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of Ag/Co colloid removal technology, so that it is not easy to decompose by radiation or biodecomposition, avoid the amount of radioactive waste, and improve the adsorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the removal of Ag-EDTA complex

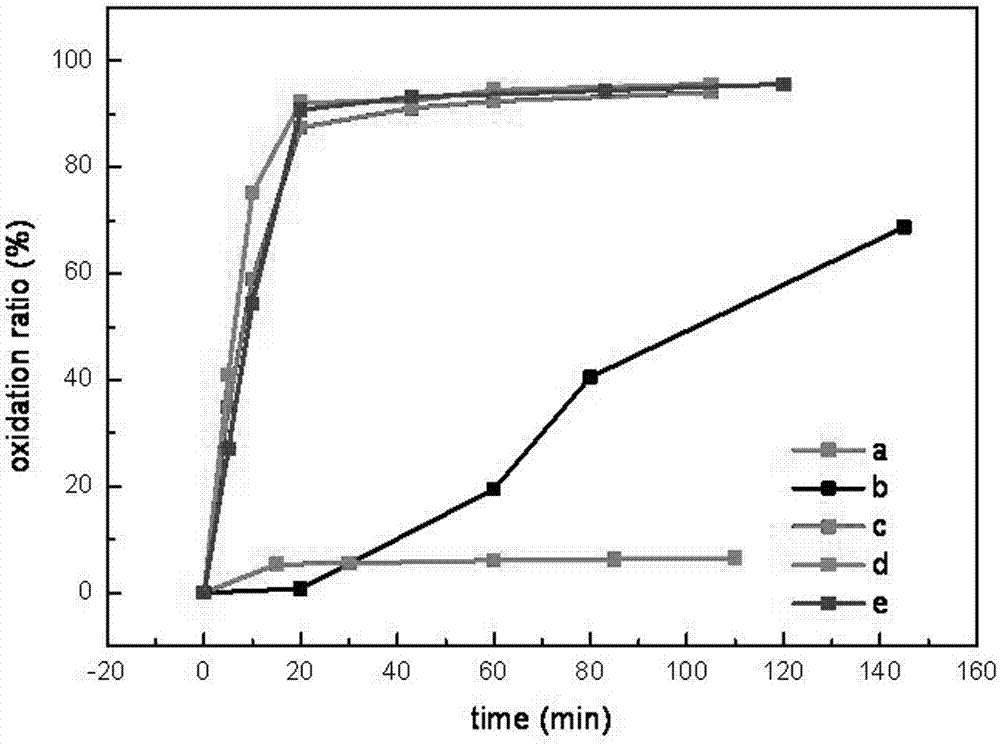

[0047] Prepare AgNO with Ag mass concentration of 20mg / L 3 Solution, add equimolar EDTA-2Na to form Ag-EDTA complex solution. The solution was distilled in a flask to simulate an evaporator, the effluent was collected, and the concentration of Ag was determined to be 0.51 mg / L. Therefore, the decontamination efficiency of the evaporation process for the Ag-EDTA complex was 97%. The slip-out liquid is injected into the membrane treatment unit, and after adopting the ultrafiltration (UF) process, the control concentration ratio is 10, the concentration of Ag in the concentrate is 3.06mg / L, and the concentration of Ag in the permeate is 0.23mg / L, so The removal efficiency of the ultrafiltration membrane unit to Ag-EDTA is 55%. Add 30% H to the concentrate 2 o 2 Aqueous solution, so that its volume ratio to the concentrated solution is 0.1mL / L. Inject the mixed solution into the ultraviolet catalytic reactor and adjust the...

Embodiment 2

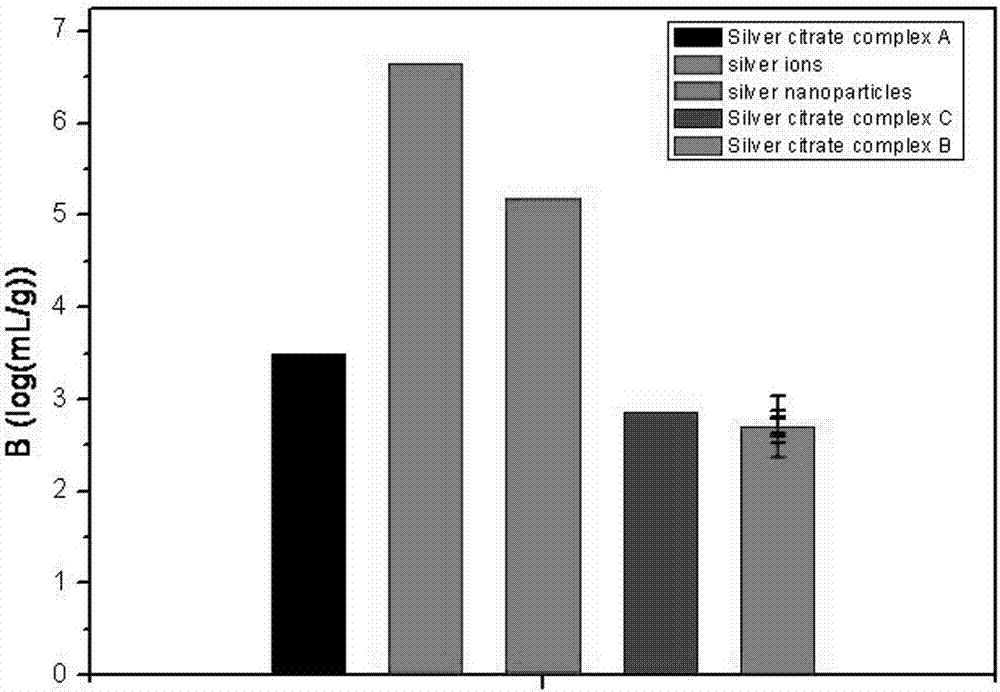

[0048] Embodiment 2: the removal of Ag-citric acid complex

[0049] Prepare AgNO with Ag mass concentration of 20mg / L 3 solution, adding equimolar sodium citrate to form Ag-citric acid complex solution. The solution was distilled in a flask to simulate an evaporator, and the effluent was collected, and the concentration of Ag was determined to be 4.01 mg / L, so the decontamination efficiency of the evaporation process for the Ag-citric acid complex was 80%. The slip-out liquid is injected into the membrane treatment unit, and after adopting the nanofiltration (NF) process, the concentration ratio is controlled to be 10, the concentration of Ag in the concentrate is 36.7mg / L, and the concentration of Ag in the permeate is 0.38mg / L, so The removal efficiency of the nanofiltration membrane unit to Ag-citric acid is 90.5%. Add 30% H to the concentrate 2 o 2 Aqueous solution, so that its volume ratio to the concentrated solution is 0.1mL / L. Inject the mixed solution into the ul...

Embodiment 3

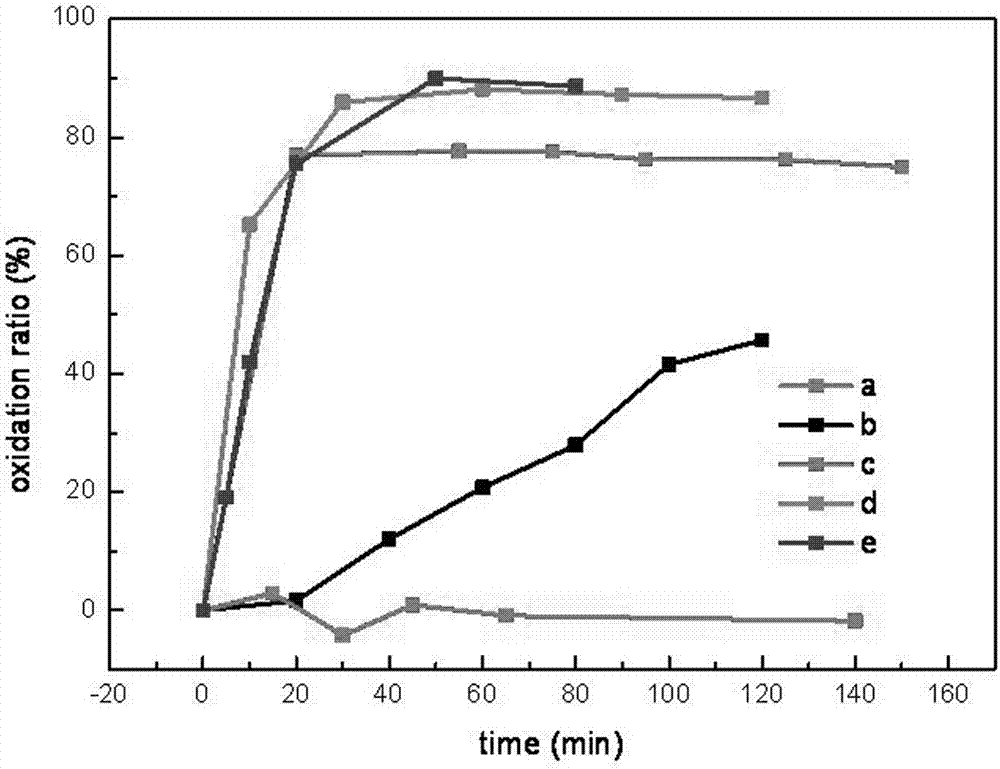

[0050]Example 3: Removal of Ag-surfactant complexes

[0051] Prepare AgNO with Ag mass concentration of 20mg / L 3 solution, adding surfactant BH3 commonly used in nuclear power plants to form Ag-BH3 complex solution. The solution was distilled in a flask to simulate an evaporator, the effluent was collected, and the Ag concentration was determined to be 10.19 mg / L, so the decontamination efficiency of the evaporation process on the Ag-BH3 complex was 49%. The effluent is injected into the membrane treatment unit, and after being treated by reverse osmosis (RO), the concentration ratio is controlled to be 10, the concentration of Ag in the concentrate is 97.2mg / L, and the concentration of Ag in the permeate is 0.53mg / L, so The removal efficiency of the reverse osmosis membrane unit to the Ag-BH3 complex is 94.8%. Add 30% H to the concentrate 2 o 2 Aqueous solution, so that its volume ratio to the concentrated solution is 0.4mL / L. Inject the mixed solution into the ultraviol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com