MnAlC-based high coercive force permanent magnetic material and preparation method thereof

A high coercivity, permanent magnet material technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem of not getting rid of the restriction of rare earth elements, and achieve the effect of refining magnetic particles and improving coercivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

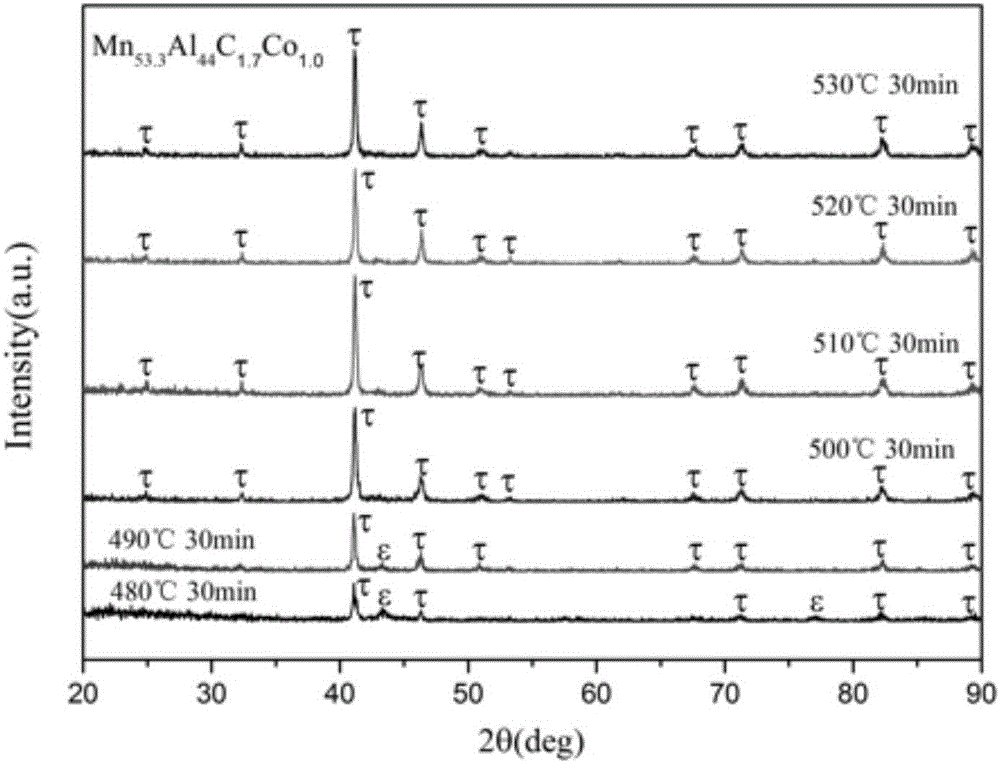

[0030] Particles of manganese, aluminum, carbon and transition metal cobalt with a purity of 99.95% are given the nominal formula Mn 53.3 Al 44 C 1.7 co 1.0 Make a ratio. During smelting, in order to make the alloy composition as uniform as possible, an induction melting furnace is selected, and in order to prevent the reaction between metal aluminum and the crucible, a boron nitride crucible is selected during induction smelting. The steps of pre-pumping, scrubbing and high-vacuumizing the induction melting furnace make the chamber pressure at 10 -4 -10 -5Pa, repeated smelting 3-4 times under this vacuum condition to obtain Mn with uniform composition 53.3 al 44 C 1.7 co 1.0 Master alloy ingot. The master alloy ingot obtained after smelting was ground with a grinding wheel to remove the surface scale, and then mechanically crushed to obtain a soybean-sized block alloy for rapid melt quenching in a quartz tube. Before the rapid quenching, the broken alloy is alternat...

Embodiment 2

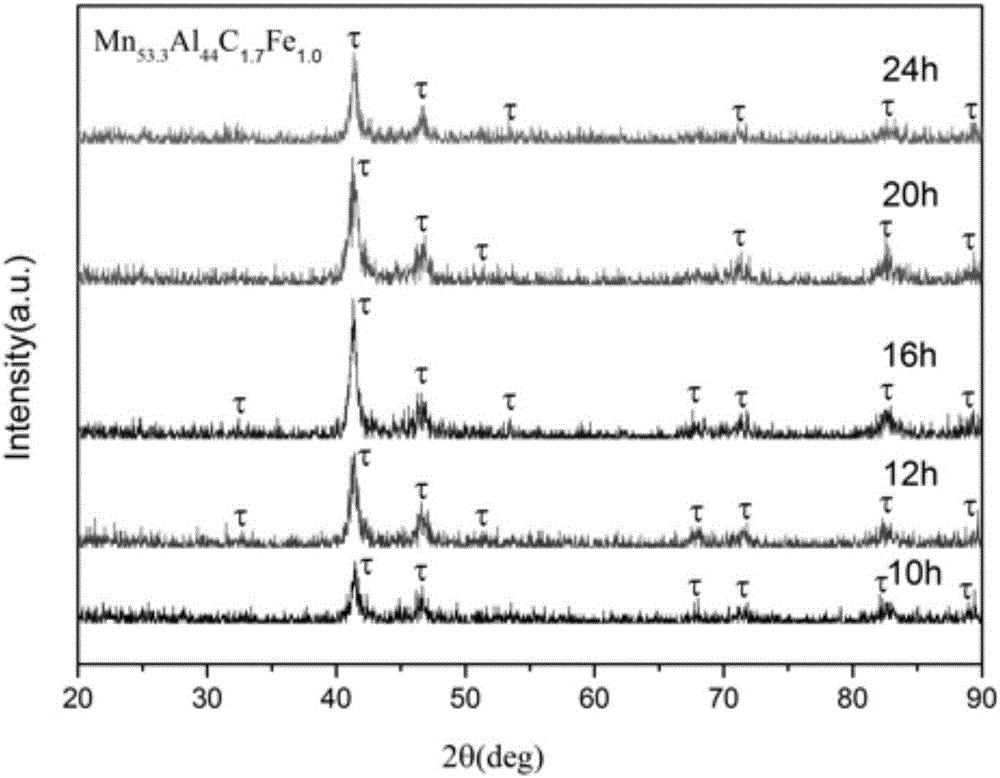

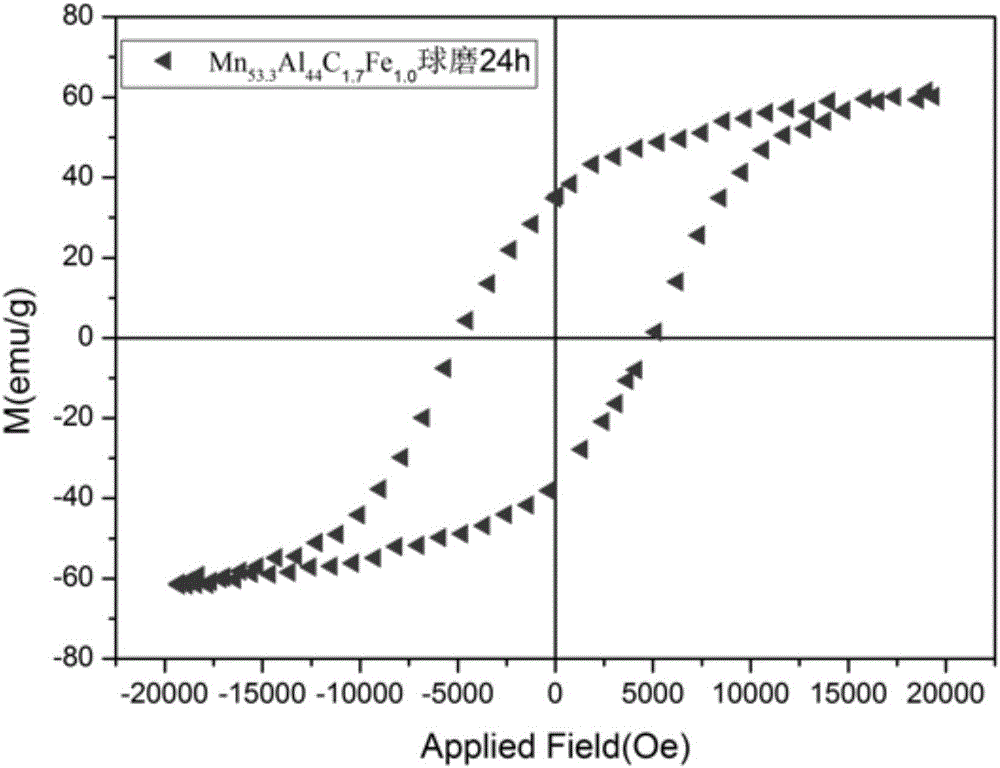

[0032] Particles of manganese, aluminum, carbon and transition metal iron with a purity of 99.95% are given the nominal molecular formula Mn 53.3 al 44 C 1.7 Fe 1.0 Make a ratio. During smelting, in order to make the alloy composition as uniform as possible, an induction melting furnace is selected, and in order to prevent the reaction between metal aluminum and the crucible, a boron nitride crucible is selected during induction smelting. The steps of pre-pumping, scrubbing and high-vacuumizing the induction melting furnace make the chamber pressure at 10 -5 Pa, repeated smelting 3-4 times under this vacuum condition to obtain Mn with uniform composition 53.3 al 44 C 1.7 Fe 1.0 Master alloy ingot. The master alloy ingot obtained after smelting was ground with a grinding wheel to remove the surface scale, and then mechanically crushed to obtain a soybean-sized block alloy for rapid melt quenching in a quartz tube. Before the rapid quenching, the broken alloy is alterna...

Embodiment 3

[0034] Manganese, aluminum, carbon, and transition metal nickel particles with a purity of 99.95% were given the nominal formula Mn 53.3 al 43.5 C 1.7 Ni 1.5 Make a ratio. During smelting, in order to make the alloy composition as uniform as possible, an induction melting furnace is selected, and in order to prevent the reaction between metal aluminum and the crucible, a boron nitride crucible is selected during induction smelting. The steps of pre-pumping, scrubbing and high-vacuumizing the induction melting furnace make the chamber pressure at 10 -5 Pa, repeated smelting 3-4 times under this vacuum condition to obtain Mn with uniform composition 53.3 al 43.5 C 1.7 Ni 1.5 Master alloy ingot. The master alloy ingot obtained after smelting was ground with a grinding wheel to remove the surface scale, and then mechanically crushed to obtain a soybean-sized block alloy for rapid melt quenching in a quartz tube. Before the rapid quenching, the broken alloy is alternately ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com