Semiconductor device and formation method thereof

A technology for semiconductors and devices, applied in the field of semiconductor devices and their formation, can solve the problems of easy blocking of device contact, easy residues on the surface of semiconductor devices, device yield, yield impact, etc., so as to reduce device manufacturing costs, reduce quantity, The effect of strong removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

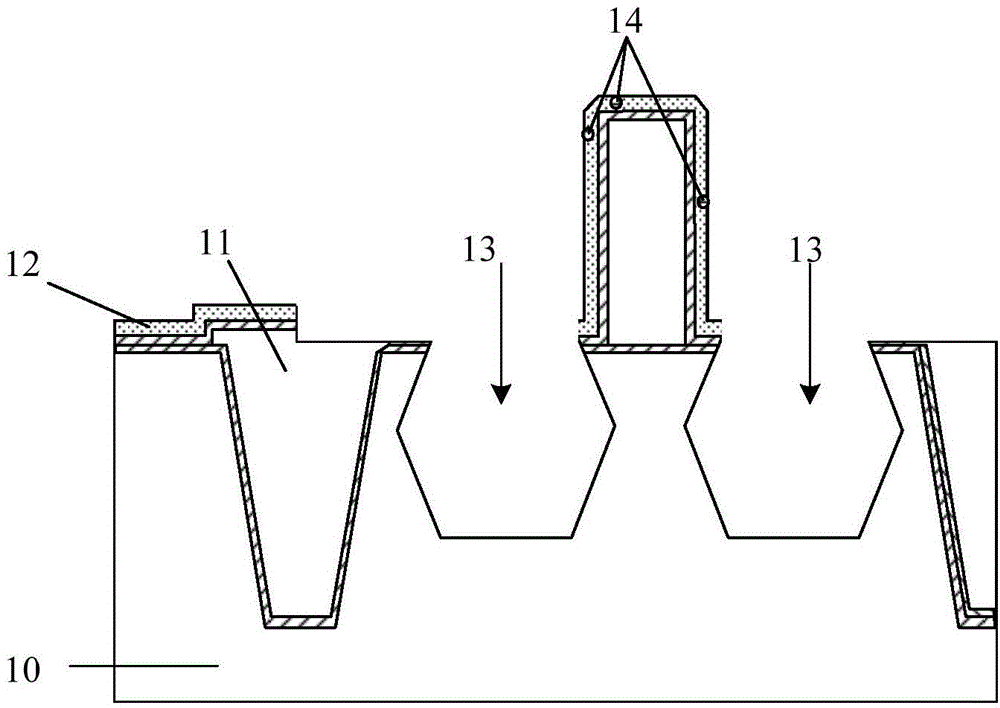

[0042] It can be seen from the background technology that in the prior art, the semiconductor device is cleaned after the epitaxial growth of the stress layer. The cleaning step is likely to form many tiny defects on the surface of the semiconductor device. The cause of the defect formation is analyzed in combination with the device formation process:

[0043] Such as figure 1 As shown, in the process of epitaxially growing boron-doped germanium silicon as a stress layer, after the isolation structure 11 is formed in the substrate 10, and before the epitaxial growth of the stress layer, the semiconductor device undergoes sequentially: depositing the protective layer 12 and etching the substrate to form Steps such as the groove 13, any one of these steps is likely to generate pollutants and etching residues (pollutants 14), and these pollutants remain on the surface of the protective layer 12 to form defects.

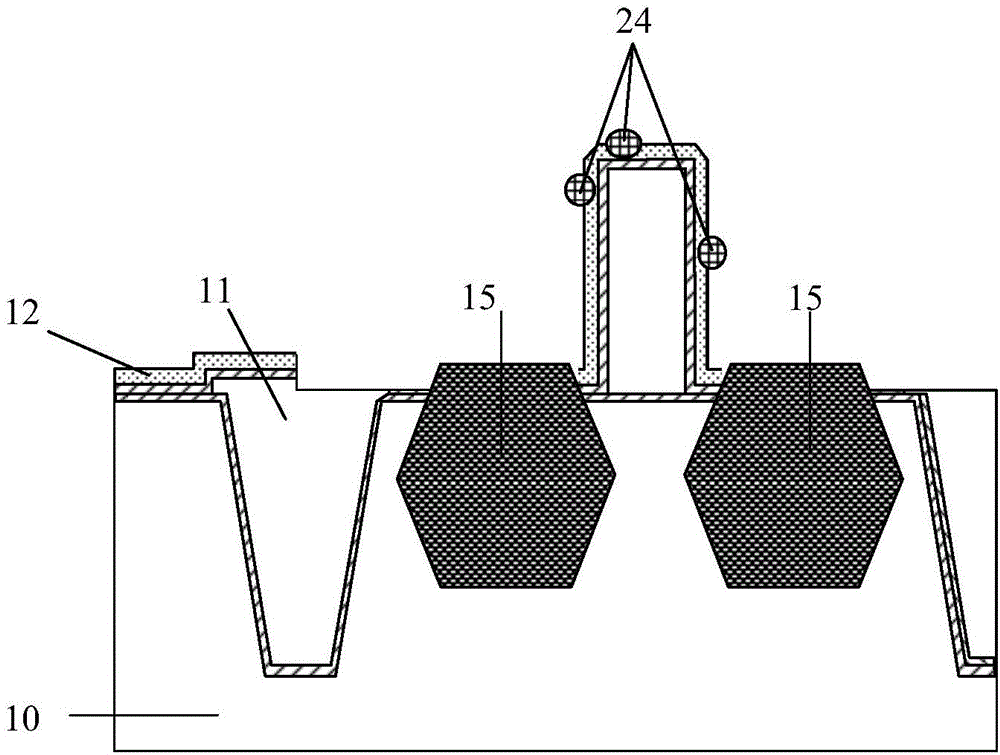

[0044] Such as figure 2 As shown, the pollutant 14 becomes the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com