Multi-flavored dried sweet potato manufacturing complete equipment provided with seasoning and thermal-insulation mixing mechanism

A complete set of dried sweet potato technology, which is applied in the field of multi-flavor dried sweet potato production complete sets of equipment, can solve the problems of unfavorable large-scale production management, uneven drying of sweet potato, inconsistent temperature and cooling, etc., and achieves the advantages of large-scale production management and simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

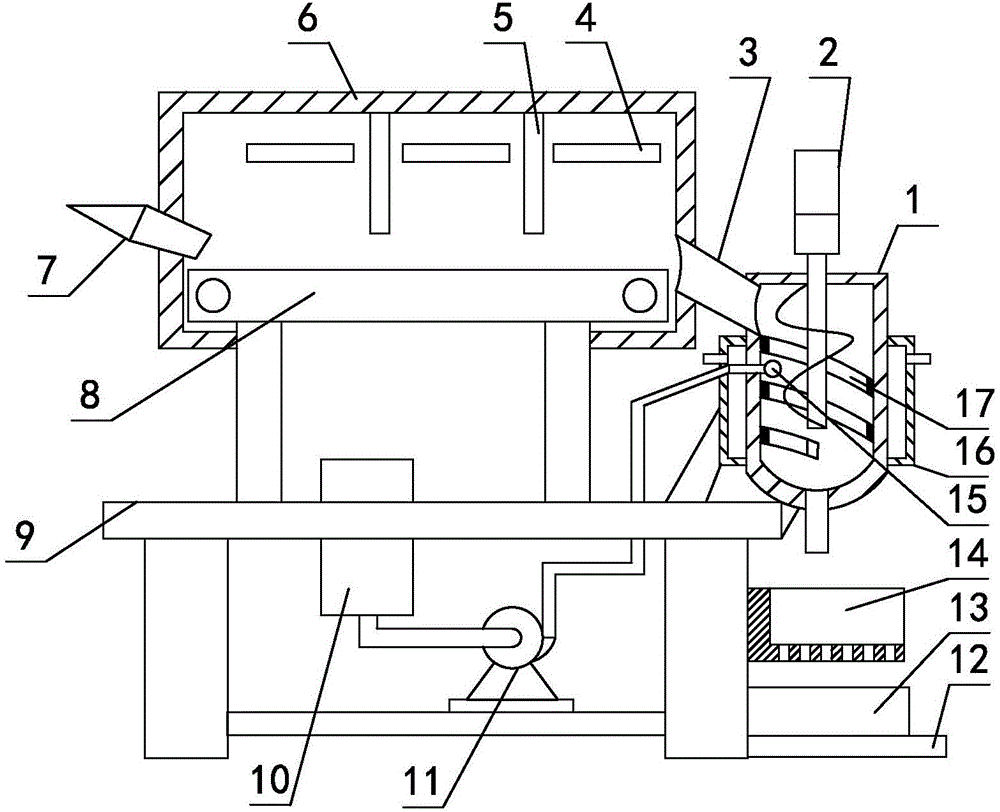

[0022] Such as figure 1 As shown, the multi-flavor dried sweet potato with seasoning and heat preservation mixing mechanism is made into a complete set of equipment, including a workbench 9 and a heating box 6, and a high-temperature-resistant belt conveyor 8 is horizontally installed on the workbench 9. The conveying part is set in the heating box 6, the left side of the heating box 6 is provided with a material inlet 7, and the right side is provided with a material outlet 3, and the upper half of the heating box 6 is sequentially provided with two pieces from left to right. The partition 5, the partition 5 divides the upper half of the heating box 6 into three heating zones with different temperatures, and an electric heater 4 for controlling the temperature independently is installed in each heating zone, and the discharge port 3 is connected with a Mixing tank 1, agitator 2 is installed on the mixing tank 1, mixing tank 1 is installed on the workbench 9, is provided with ...

Embodiment 2

[0026] Further change on the basis of Embodiment 1, the distance between the lower end of the partition 5 and the belt conveyor 8 becomes 70mm; the thickness of the partition 5 becomes 30mm; the thickness of the second insulation layer becomes 50mm. Others are the same as embodiment one.

Embodiment 3

[0028] Further change on the basis of Embodiment 1, the distance between the lower end of the partition 5 and the belt conveyor 8 becomes 60mm; the thickness of the partition 5 becomes 25mm; the thickness of the second insulation layer becomes 40mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com