Oxidized hydroxypropyl starch empty capsules and preparation process thereof

A technology of oxidizing hydroxypropyl and hollow capsules, which is applied in the field of pharmaceuticals, can solve the problems of high uniformity of dipped film, and achieve the effects of good transparency, wide adaptability and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

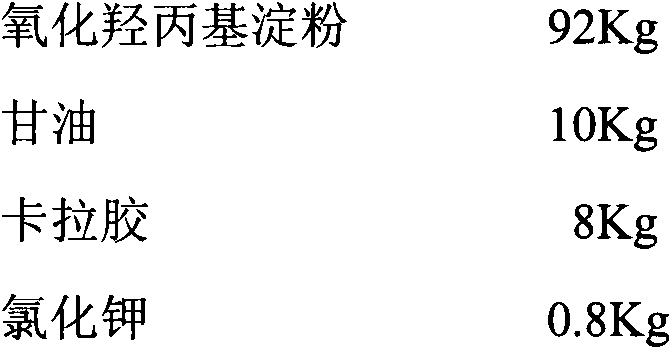

[0032] prescription:

[0033]

[0034] Preparation method: (1) Sol: Add 92Kg of oxidized hydroxypropyl starch, 10Kg of glycerin, 8Kg of carrageenan, and 0.8Kg of potassium chloride into 500Kg of water in proportion, stir well and raise the temperature to 80°C, keep the temperature at 80°C and stir for 0.5 hours Get glue.

[0035] (2) Glue cultivation: Keep the temperature of the glue liquid at 80°C to stop, and remove air bubbles.

[0036] (3) Glue dipping: Then enter the automatic glue dipping production line to automatically dip glue, dry, shell, cut, buckle, light inspect, sterilize, and get the product. When dipping the glue, the temperature of the glue solution is 55°C, the temperature of the dipping mold is 30°C, the ambient temperature is 25°C, the temperature of the drying tunnel is 60°C during drying, and the drying time is 1 hour.

[0037] With reference to the method stipulated in the Chinese Pharmacopoeia 2015 edition, the hard capsules prepared above were mea...

Embodiment 2

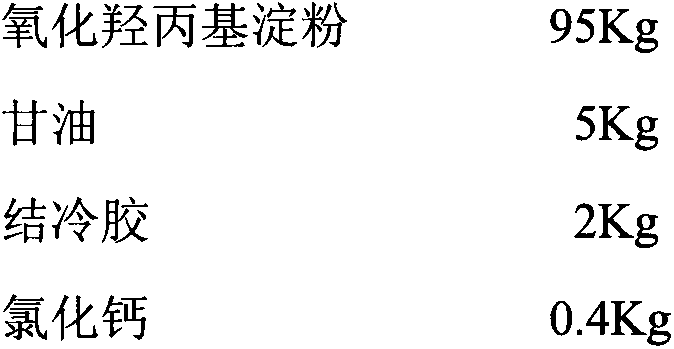

[0043] prescription:

[0044]

[0045] Preparation method: (1) Sol: Add 95Kg of oxidized hydroxypropyl starch, 5Kg of glycerin, 2Kg of gellan gum, and 0.4Kg of calcium chloride into 400Kg of water in proportion, stir well and raise the temperature to 85°C, keep the temperature at 85°C and stir for 1 Get glue in hours.

[0046] (2) Glue cultivation: Keep the temperature of the glue solution at 85°C to keep the glue still, and remove the air bubbles.

[0047] (3) Glue dipping: Then enter the automatic glue dipping production line to automatically dip glue, dry, shell, cut, buckle, light inspect, sterilize, and get the product. When dipping the glue, the temperature of the glue solution is 50°C, the temperature of the dipping mold is 20°C, the ambient temperature is 20°C, the temperature of the drying tunnel is 70°C during drying, and the drying time is 0.5 hours.

[0048] With reference to the method stipulated in the Chinese Pharmacopoeia 2015 edition, the hard capsules pr...

Embodiment 3

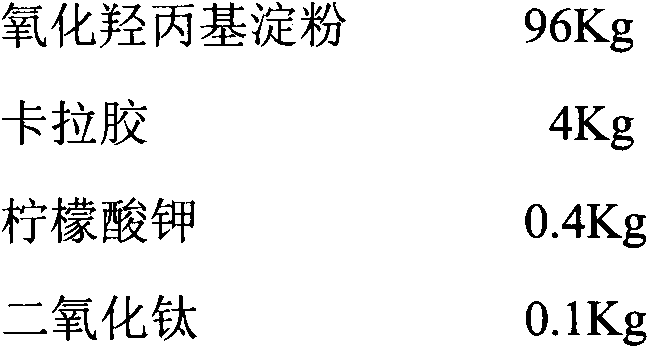

[0051] prescription:

[0052]

[0053] Preparation method: (1) Sol: Add 96Kg of oxidized hydroxypropyl starch, 4Kg of carrageenan, 0.4Kg of potassium citrate, and 0.1Kg of titanium dioxide into 500Kg of water in proportion, stir well and heat up to 80°C, keep stirring at 80°C 2 hours to get glue.

[0054] (2) Glue cultivation: Keep the temperature of the glue solution at 85°C to keep the glue still, and remove the air bubbles.

[0055] (3) Glue dipping: Then enter the automatic glue dipping production line to automatically dip glue, dry, shell, cut, buckle, light inspect, sterilize, and get the product. When dipping the glue, the temperature of the glue solution is 50°C, the temperature of the dipping mold is 25°C, the ambient temperature is 25°C, the temperature of the drying tunnel is 40°C during drying, and the drying time is 2 hours.

[0056] With reference to the method stipulated in the Chinese Pharmacopoeia 2015 edition, the hard capsules prepared above were measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com