An iron-based Fischer-Tropsch catalyst, its preparation method and application, and a Fischer-Tropsch synthesis method

A technology of Fischer-Tropsch synthesis and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of inability to control the stability of silica sol and accelerate the development of silica sol itself. Cross-linking, changing the properties of silica sol, etc., to achieve the effect of high low-temperature activity, small average pore size, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

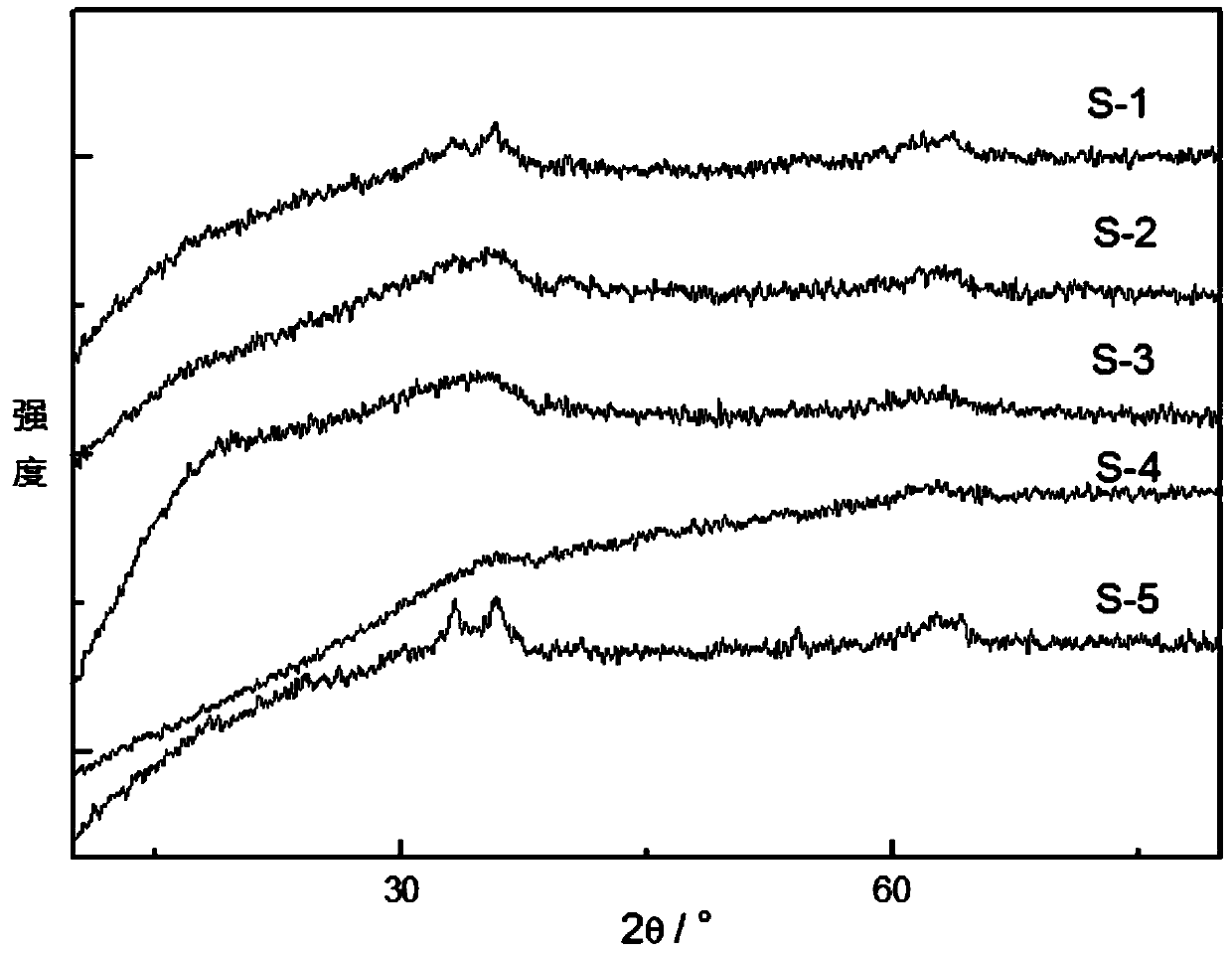

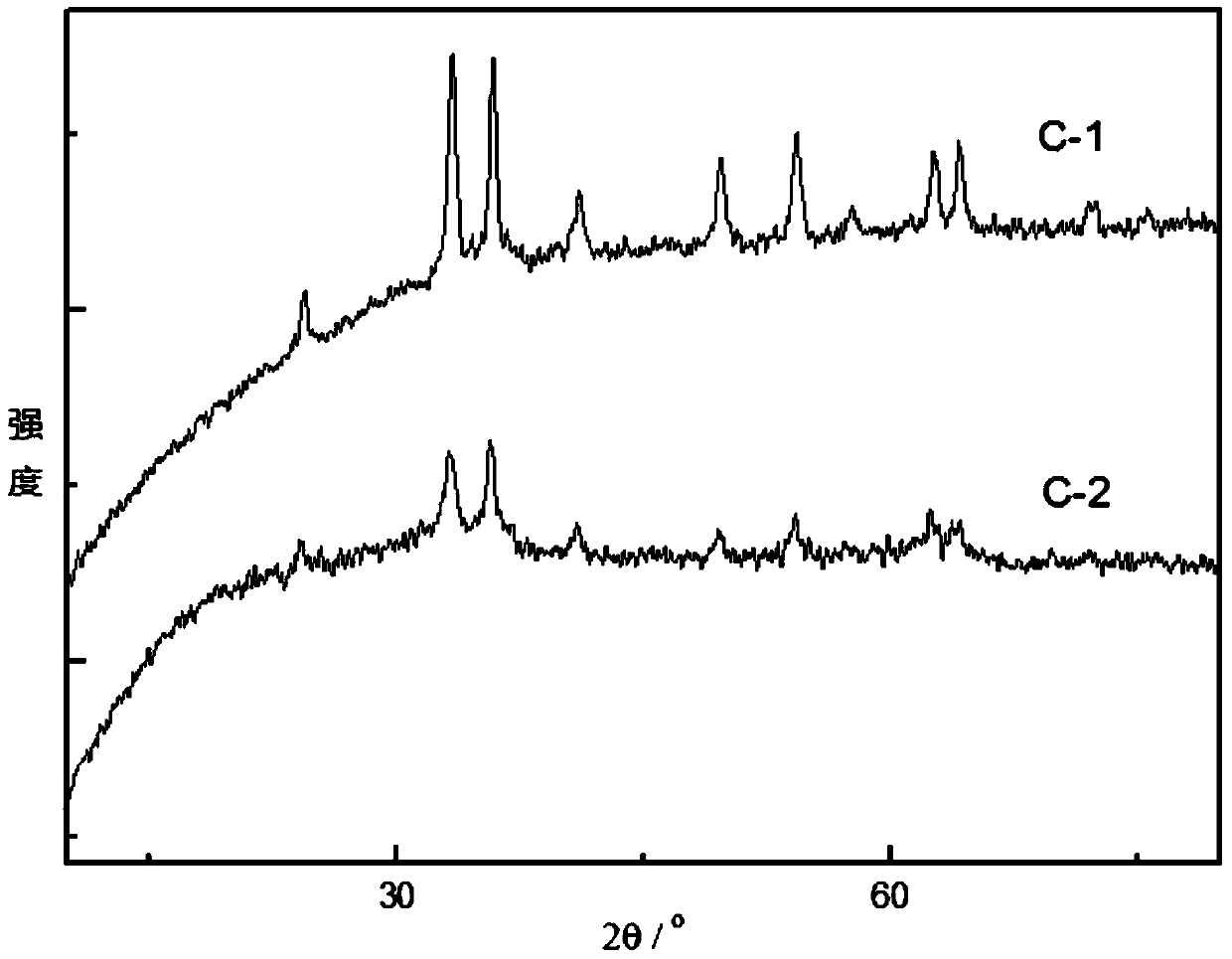

Image

Examples

preparation example Construction

[0084] The invention provides an iron-based Fischer-Tropsch catalyst obtained according to the preparation method of the invention.

[0085] The invention provides the application of the iron-based Fischer-Tropsch catalyst described in the invention in Fischer-Tropsch synthesis.

[0086] The invention provides a Fischer-Tropsch synthesis method, which comprises: under Fischer-Tropsch synthesis conditions, contacting synthesis gas with a Fischer-Tropsch synthesis catalyst, wherein the Fischer-Tropsch synthesis catalyst is the iron-based Fischer-Tropsch synthesis catalyst described in the present invention catalyst.

[0087] According to the method of the present invention, preferably the Fischer-Tropsch synthesis conditions include: the temperature is 220-270°C, the H in the synthesis gas 2 The molar ratio to CO is (1-3):1.

preparation example 1

[0090] Weigh 10kg of Fe(NO 3 ) 3 9H 2 O, 0.22kg of Cu(NO 3 ) 2 ·3H 2 0, add the deionized water of 40L and stir to dissolve, obtain iron salt mixed solution;

[0091] Weigh 5.0kg of Na 2 CO 3 , 0.18kg potassium silicate, add 20L of deionized water and stir to dissolve to obtain a mixed solution of alkali and salt;

[0092] The above two mixed solutions were heated to above 70°C by means of jacket heating, and then the two pumps were used to flow the two into a vigorously stirred reactor for precipitation reaction, and the jacket of the reactor kept the temperature at 75°C. The pH value in the reactor was controlled to be 7.5 by adjusting the two pump speeds respectively, the stirring rate was 90 rpm, and the reaction time was 40 min. After the precipitation is completed, the precipitated slurry is vacuum filtered and washed repeatedly with deionized water until the conductivity of the filtrate is below 500 μS / cm, and the first filter cake 1 is obtained for use.

preparation example 2

[0094] Weigh 10kg of Fe(NO 3 ) 3 9H 2 O, 0.19kg of Cu(NO 3 ) 2 ·3H 2 0, add the deionized water of 40L and stir to dissolve, obtain iron salt mixed solution;

[0095] Weigh 5.3kg of Na 2 CO 3 , 0.15kg potassium silicate, add 20L of deionized water and stir to dissolve to obtain a mixed solution of alkali and salt;

[0096] Heat the above two mixed solutions to above 85°C respectively by means of jacket heating, and then use a pump to pump the iron salt mixed solution into the mixed solution of alkali and salt under vigorous stirring for precipitation reaction, and the jacket of the reaction kettle maintains the temperature 85°C;

[0097] Control the reaction time within 40 minutes, and finish the reaction when the pH is 7. After the precipitation is completed, the slurry is left to age for 1 hour, and then the precipitated slurry is quickly transferred to a water-cooled heat exchanger through a transfer pump to reduce the temperature of the slurry to below 40°C. Then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com