Large-area gold nanorod aligned and ordered array, preparation method and application thereof

A technology of nano-gold rods and ordered arrays, which is applied in the field of nano-materials, can solve the problem of few macroscopic large-area directional and ordered arrays of nano-gold rods, and achieve the effects of large-scale implementation, low cost, and simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

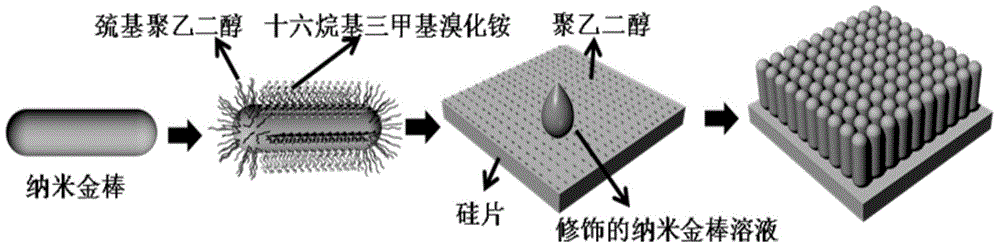

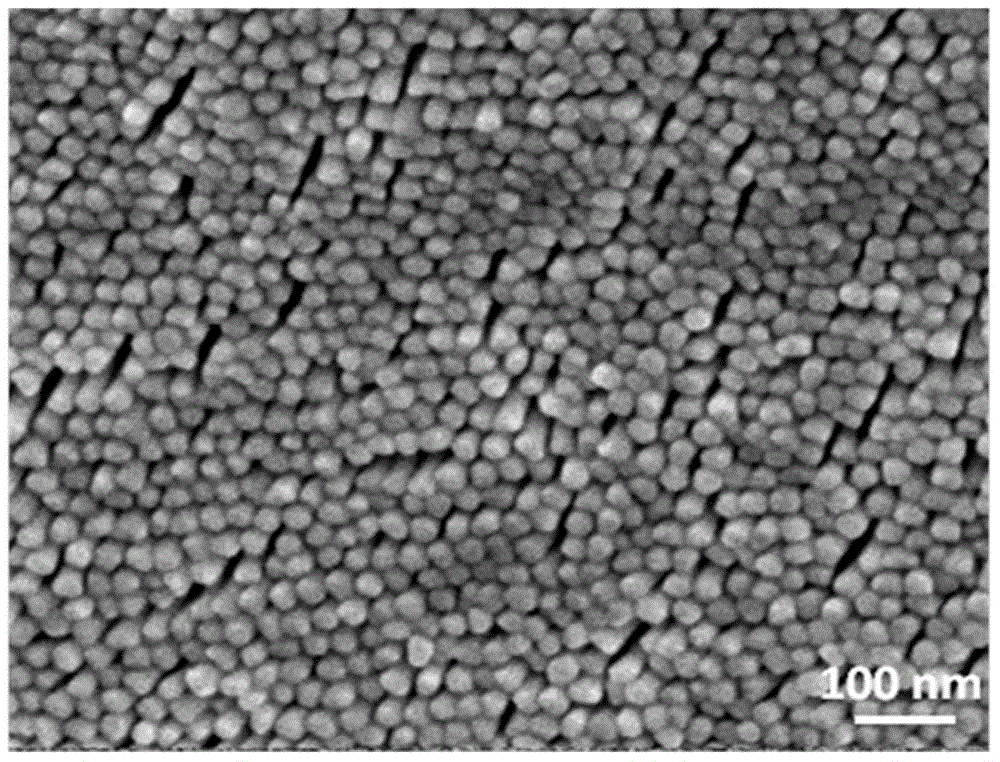

[0068] Example 1: Large-scale dense arrangement of gold nanorods vertically on the surface of silicon wafer substrate

[0069] (1) Preparation of nano-gold rods with different aspect ratios: the synthesis of nano-gold rods is based on the regrowth method of nano-crystal seeds, and there are mainly two steps. First, the synthesis of seed crystals: 10 ml of 0.2M cetyltrimethylammonium bromide aqueous solution and 10 ml of 5*10 -4 M chloroaurate aqueous solution was mixed, and then 1.2 ml of frozen 0.01 M sodium borohydride aqueous solution was added dropwise to the above solution, and then stirred at high speed for 2 minutes to obtain a yellow-brown nano-crystal seed solution. Second, the configuration of the gold nanorod growth solution: 47.5 ml of 0.1M cetyltrimethylammonium bromide aqueous solution was mixed with 2.5 ml of 0.01M chloroaurate aqueous solution. Then add 0.3 ml of 0.01M silver nitrate aqueous solution and 0.275 ml of 0.1M ascorbic acid aqueous solution, stir ...

Embodiment 2

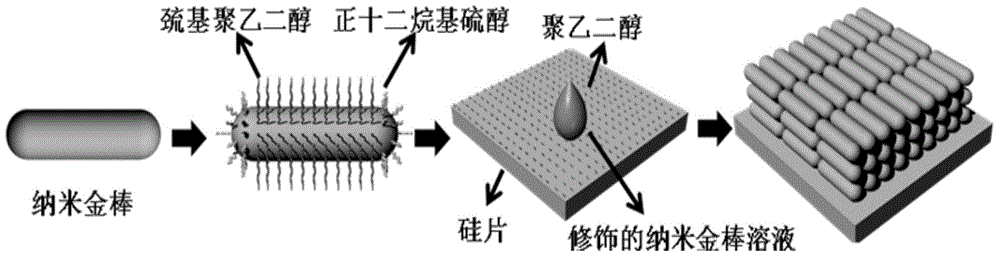

[0073] Example 2: Large-scale dense arrangement of gold nanorods spread on the surface of silicon wafer substrate

[0074] (1) Preparation of nano-gold rods with different aspect ratios: the synthesis of nano-gold rods is based on the regrowth method of nano-crystal seeds, and there are mainly two steps. First, the synthesis of seed crystals: 10 ml of 0.2M cetyltrimethylammonium bromide aqueous solution and 10 ml of 5*10 -4 M chloroaurate aqueous solution was mixed, and then 1.2 ml of frozen 0.01 M sodium borohydride aqueous solution was added dropwise to the above solution, and then stirred at high speed for 2 minutes to obtain a yellow-brown nano-crystal seed solution. Second, the configuration of the gold nanorod growth solution: 47.5 ml of 0.1M cetyltrimethylammonium bromide aqueous solution was mixed with 2.5 ml of 0.01M chloroaurate aqueous solution. Then add 0.3 ml of 0.01M silver nitrate aqueous solution and 0.275 ml of 0.1M ascorbic acid aqueous solution, stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com