Beta-dicalcium silicate and preparation method thereof

A technology of dicalcium silicate and calcium source, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the complex process of β-dicalcium silicate, the appearance of impurity in materials, and limit the promotion of β-dicalcium silicate and application issues, to achieve the effect of broadening the application, less impurity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

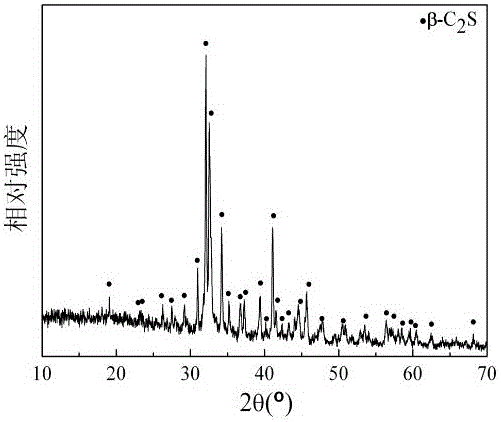

[0024] A β-dicalcium silicate and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0025] The molar ratio of calcium source: silicon source: barium source is 1: (0.2 ~ 0.8): (0.04 ~ 0.05) batching to obtain a mixture; then add 80 ~ 100wt% distilled water to the mixture, and mix evenly; Dry at 70-110°C for 12-24 hours, finely grind, press and form, the forming pressure is 50-100MPa; then keep warm for 4-5 hours under the condition of air atmosphere and 1200-1400°C, cool with the furnace, and make Get β-dicalcium silicate.

[0026] In this embodiment: the calcium source is calcium oxide; the silicon source is metasilicate; and the barium source is barium carbonate.

Embodiment 2

[0028] A β-dicalcium silicate and a preparation method thereof. Except following raw material, all the other are with embodiment 1:

[0029] In this embodiment: the calcium source is calcium hydroxide; the silicon source is silicon dioxide; the barium source is barium carbonate.

Embodiment 3

[0031] A β-dicalcium silicate and a preparation method thereof. Except following raw material, all the other are with embodiment 1:

[0032] In this embodiment: the calcium source is calcium carbonate; the silicon source is silicon dioxide; the barium source is barium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com