Method for removing calcium and magnesium impurities in lithium-rich solution by extraction process

An extraction method, lithium-rich technology, applied in the direction of lithium carbonate;/acid carbonate, etc., to achieve the effect of short time consumption, simple decalcification operation, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

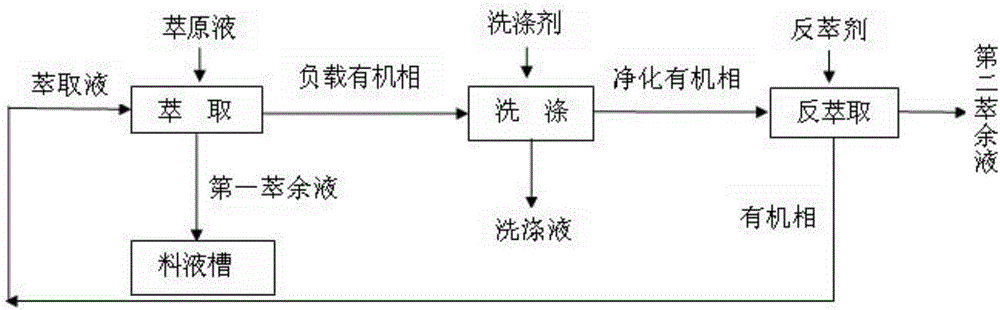

Image

Examples

example 1

[0043] The lithium-rich solution was used as the extraction solution, the pH value of the extraction solution was adjusted to 3 with calcium carbonate and the temperature was controlled at 10°C. The extractant P204 and sulfonated kerosene as a slow-release agent were used to form the extract, wherein P204 and sulfonated kerosene were mixed in a volume ratio of 1:3. After oscillating and mixing the extracting solution and the extracting solution, control the extraction equilibrium time to 10 minutes, and the number of extraction stages to 6, so that the calcium and magnesium ions in the aqueous phase enter the organic phase, and the first raffinate and the loaded organic phase are separated.

[0044] The obtained loaded organic phase was washed and purified with 2 mol / L hydrochloric acid, the number of washing stages was 4, and the purified organic phase and washing liquid were separated to obtain.

[0045] The obtained purified organic phase is back-extracted with 4.5mol / L hyd...

example 2

[0054] The lithium-rich solution was used as the extraction solution, the pH value of the extraction solution was adjusted to 4 with calcium carbonate and the temperature was controlled at 30°C. The extractant P507 and sulfonated kerosene as a slow-release agent were used to form the extract, and P204 and sulfonated kerosene were mixed in a volume ratio of 1:2. After oscillating and mixing the extracting solution and the extracting solution, control the extraction equilibrium time to 15 minutes, and the number of extraction stages to 5, so that the calcium and magnesium ions in the aqueous phase enter the organic phase, and separate to obtain the first raffinate and the loaded organic phase.

[0055] The obtained loaded organic phase was washed and purified with 3 mol / L hydrochloric acid, the number of washing stages was 5, and the purified organic phase and the washing liquid were separated to obtain the purified organic phase.

[0056] The obtained purified organic phase is ...

example 3

[0065] The lithium-rich solution was used as the extraction solution, the pH value of the extraction solution was adjusted to 5 with calcium carbonate and the temperature was controlled at 50°C. The extractant P350 and sulfonated kerosene as a slow-release agent were used to form the extract, and P204 and sulfonated kerosene were mixed in a volume ratio of 1:1. After oscillating and mixing the extracting solution and the extracting solution, the extraction equilibrium time is controlled to be 30 minutes, and the number of extraction stages is 7, so that the calcium and magnesium ions in the aqueous phase enter the organic phase, and the first raffinate and the loaded organic phase are separated.

[0066] The obtained loaded organic phase was washed and purified with 0.5 mol / L hydrochloric acid, the number of washing stages was 6, and the purified organic phase and washing liquid were obtained by separation.

[0067] The obtained purified organic phase is back-extracted with 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com