A kind of advanced treatment method of selenium-containing wastewater

A technology for advanced treatment and wastewater, applied in the field of advanced treatment of selenium-containing wastewater, can solve problems such as inability to treat selenium-containing wastewater for a long time, limited anaerobic biological tolerance, and anaerobic reaction effects, and achieve environmental and economic benefits. , the effect of improving biodegradability and high selenium removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

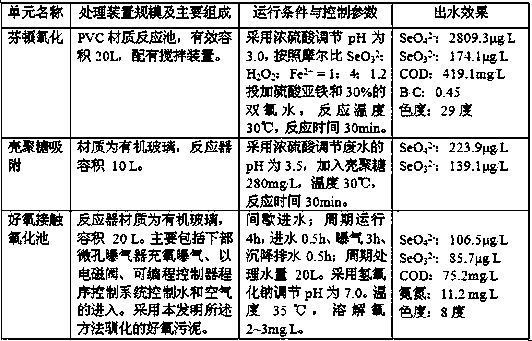

[0024] The process flow of the invention is adopted to treat the selenium-containing wastewater. Wastewater water quality: pH is 7.3, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 326.3μg / L, selenite ion (SeO 3 2- ) concentration was 269.7μg / L, COD (Cr method, the same below) was 483mg / L, ammonia nitrogen was 53.1 mg / L, B / C: 0.34, and chromaticity was 98 degrees. The main test device configuration, operating conditions and treatment effects of each treatment unit are shown in Table 1.

[0025] Table 1 Main processing unit composition and processing effect of Embodiment 1

[0026]

[0027] As can be seen from Table 1, adopting the treatment process of the present invention, the removal rate of selenium reaches 97.5%, the removal rate of COD is 92%, the removal rate of ammonia nitrogen is 91.5%, and the chroma is less than 10. The treated wastewater meets the standard discharge requirements, and more than 90% of th...

Embodiment 2

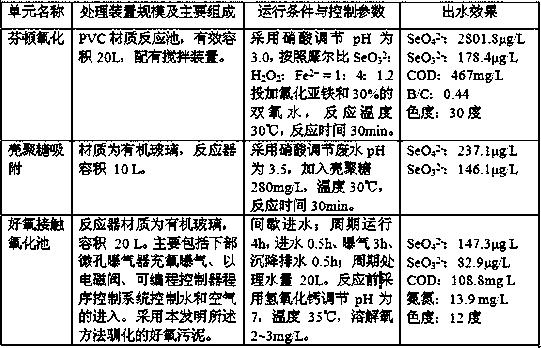

[0029] The method of the invention is used to treat the selenium-containing wastewater. Wastewater water quality: pH is 6.9, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 1228.3μg / L, selenite ion (SeO 3 2- ) concentration is 1757.7μg / L, COD: 637mg / L, ammonia nitrogen: 75.1 mg / L, B / C: 0.17, chromaticity 123 degrees. The main test device configuration, operating conditions and treatment effects of each treatment unit are shown in Table 2.

[0030] Table 2 Main processing unit composition and processing effect of embodiment 2

[0031]

[0032] As can be seen from Table 2, using the treatment process of the present invention, the removal rate of selenium reaches 94.8%, the removal rate of COD is 91%, the removal rate of ammonia nitrogen is 90.4%, and the chroma is <10. The treated wastewater meets the standard discharge requirements, and more than 90% of the selenium pollutants are efficiently recovered.

Embodiment 3

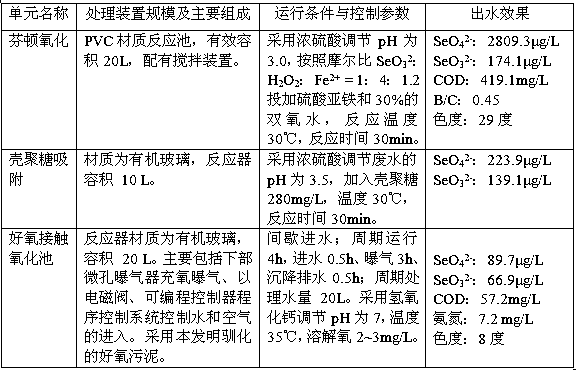

[0034] The water quality, treatment unit and operating conditions of selenium-containing wastewater are the same as in Example 2, except that cross-linked chitosan is used for adsorption, and the preparation method of cross-linked chitosan is: take 1.0 g soluble chitosan and dissolve it in 80 mL In 1% acetic acid solution, stir and dissolve to form a transparent mucus; at 50°C, slowly add 1.0mL epichlorohydrin (analytical grade) dropwise to the solution, then gradually add dropwise 10mL 5% sodium hydroxide, alternately Suction filtration after 20 hours, repeated washing with deionized water and acetone, suction filtration, vacuum drying and sieving for later use. The main test device configuration, operating conditions and treatment effects of each treatment unit are shown in Table 3.

[0035] Table 3 Main processing unit composition and processing effect of embodiment 3

[0036]

[0037] As can be seen from Table 3, adopting the treatment process of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com