A kind of treatment method of the waste water produced in the production process of acrylic fiber

A treatment method and production process technology are applied in the field of treatment of wastewater generated in the production process of acrylic fibers, which can solve the problems that nitrogen-containing pollutants cannot be treated up to standard and are difficult to degrade, and achieve the effects of reducing impact, removing efficiently and realizing toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

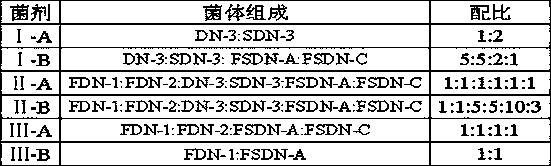

[0016] The preparation of embodiment 1 microbial bacterial agent

[0017] 1. Cultivation of a single bacterial strain: FDN-1, FDN-2, DN-3, SDN according to the methods described in CN2010106224.6, CN2010106240.5, CN2010106203.4, CN201010536169.0, CN201110353731.0 and CN201110353742.9 respectively -3. The six bacterial strains FSDN-A and FSDN-C were cultured to the logarithmic phase, and the seed liquid of a single bacterial strain was obtained.

[0018]2. Preparation of microbial inoculum: if the inoculum added to the anaerobic hydrolysis unit contains Paracoccus denitrificans DN-3 and / or Methylobacterium SDN-3, follow the method described in Example 1 of CN201210130644.3 or CN201210130645.8 The bacterial agent is prepared, wherein the culture conditions are temperature 25-35° C., pH value 6.5-10.0, and DO lower than 0.5 mg / L. If there are four kinds of bacteria at the same time, the four kinds of bacteria of Paracoccus denitrifica DN-3, Methylobacterium SDN-3, Corkia palustr...

Embodiment 2

[0025] The COD concentration in the wastewater produced by an acrylic fiber production plant is about 1200mg / L, the BOD concentration is about 150mg / L, and the total nitrogen concentration is about 100mg / L. CN - The concentration is about 5.2mg / L, NH 3 -The concentration of N is about 60mg / L, the pH value is 8.8, and the combined process of anaerobic hydrolysis-aerobic contact oxidation-biological denitrification is used for treatment. The wastewater first enters the anaerobic hydrolysis unit, the residence time is 6 hours, the pH is controlled at 6.0, and the temperature is 30°C. After anaerobic treatment, the wastewater is transported to the aerobic contact oxidation unit, the residence time is 10 hours, and the pH is controlled at 7.5~7.8. DO: 3.2~3.5mg / L, temperature 30°C, the wastewater treated by the aerobic contact oxidation unit enters the biological denitrification unit for denitrification and further removal of COD, the residence time is 8 hours, and the pH is contro...

Embodiment 3

[0027] The COD concentration in the wastewater produced by a dry acrylic fiber production plant is about 1800mg / L, the BOD concentration is about 250mg / L, and the TN concentration is about 260mg / L. CN - The concentration is about 7.4mg / L, NH 3 -The concentration of N is about 160mg / L, the pH value is 7.8, and it is treated by the combined process of anaerobic hydrolysis-aerobic contact oxidation-biological denitrification. The wastewater first enters the anaerobic hydrolysis unit, the residence time is 8 hours, the pH is controlled at 6.5, and the temperature is 30°C. After anaerobic treatment, the wastewater is sent to the aerobic contact oxidation unit, the residence time is 10 hours, and the pH is controlled at 7.5~8.0, DO: 3.5~4.0mg / L, temperature 30℃, the wastewater treated by the aerobic contact oxidation unit enters the biological denitrification unit for denitrification and further removal of COD, the residence time is 12 hours, the pH is controlled at 8.0~8.5, DO: 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com