Treatment method of polyether polyol production tail water

A technology of polyether polyol and treatment method, which is applied in the field of environmental engineering, can solve problems such as complex process and high cost, achieve high degradation efficiency, low operating cost, and reduce the demand for chemical carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

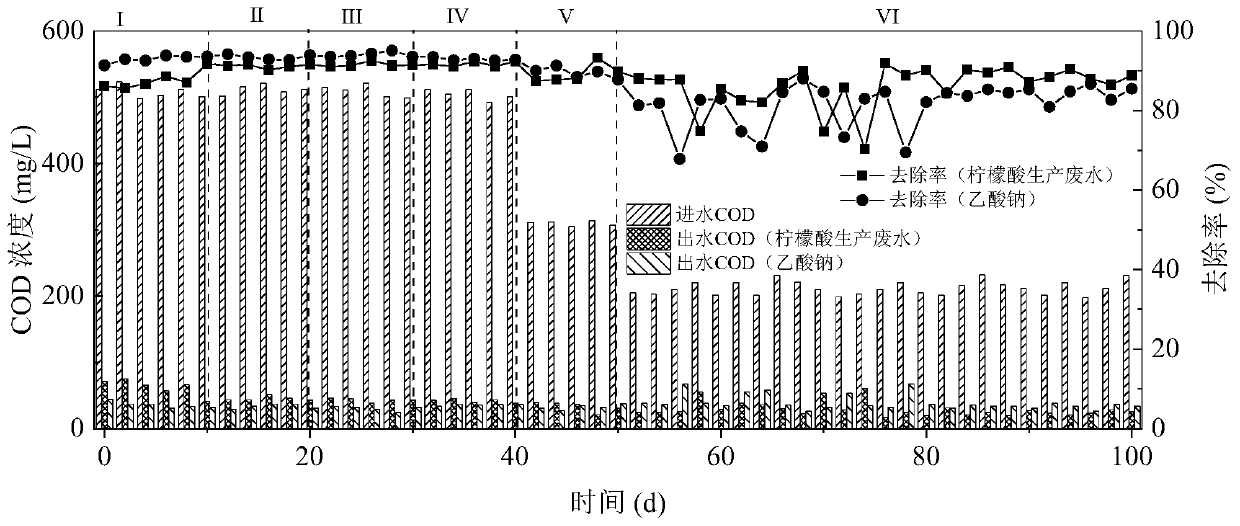

[0030] In this example, the physical and chemical properties of the polyether polyol production tail water and citric acid production wastewater used are shown in Table 1. The co-metabolic degradation process of polyether polyol production tail water is divided into six stages (gradually increasing the COD concentration of polyether polyol production tail water influent, while gradually reducing the COD concentration of citric acid production wastewater in the influent water).

[0031] (1) Phase I:

[0032] 500mL of citric acid production wastewater (adjusting the COD concentration to 500mg / L) was pumped into the sequencing batch bioreactor (the hydraulic retention time was 12h), and ammonium chloride and potassium dihydrogen phosphate were added at the same time to adjust the COD in the reactor influent :TN:TP=100:5:1, after 10 days of stable operation, the average COD removal rate of the reactor effluent at this stage is 86.6%.

[0033] (2) Phase II:

[0034] 500mL mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com