Glass-ceramic for laser protection and preparation method thereof

A technology of laser protection and glass-ceramics, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., to achieve low expansion coefficient, good thermal shock and mechanical shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

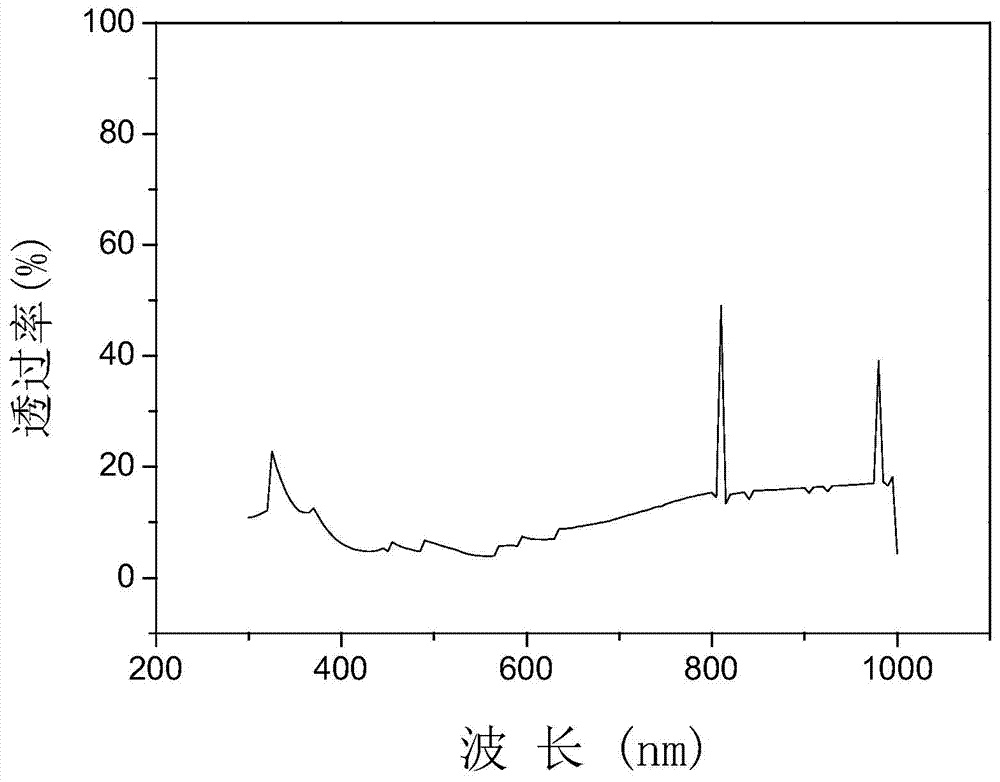

Image

Examples

Embodiment 1

[0020] A kind of laser protective glass-ceramic material of the present invention and preparation method thereof are as follows:

[0021] a. The oxidation composition of the basic glass is: SiO 2 (54wt%), Al 2 o 3 (22wt%), Li 2 O (4.3wt%), SrO (5wt%), MgO (5wt%), B 2 o 3 (1.5wt%), Na 2 O (0.4wt%), TiO 2 (3wt%), ZrO 2 (2wt%), Er 2 o 3 (2wt%), Bi 2 o 3 (0.5wt%), Co 2 o 3 (0.2wt%), Sb 2 o 3 (0.1 wt%). Correspondingly, the raw materials used are chemically pure chemical raw materials, corresponding to: silica, alumina powder, lithium carbonate, strontium carbonate, magnesium carbonate, boric acid, soda ash, titanium oxide, zirconia, erbium oxide, oxide Bismuth, cobalt trioxide and antimony trioxide.

[0022] b. Use the above-mentioned chemical raw materials for glass batching, including batching calculation, weighing, mixing and other processes.

[0023] c. Put the glass batch material into a corundum crucible and melt it in a silicon-molybdenum furnace with a te...

Embodiment 2

[0029] a. The oxidation composition of the basic glass is: SiO 2 (59wt%), Al 2 o 3 (20wt%), Li 2 O (4wt%), SrO (3wt%), MgO (3wt%), B 2 o 3 (0.5wt%), Na 2 O (0.5wt%), TiO 2 (2wt%), ZrO 2 (3wt%), Er 2 o 3 (3wt%), Bi 2 o 3 (1.5wt%), Co 2 o 3 (0.3wt%), Sb 2 o 3 (0.2 wt%). Correspondingly, the raw materials used are chemically pure chemical raw materials, corresponding to: silica, alumina powder, lithium carbonate, strontium carbonate, magnesium carbonate, boric acid, soda ash, titanium oxide, zirconia, erbium oxide, oxide Bismuth, cobalt trioxide and antimony trioxide.

[0030] b. Use the above-mentioned chemical raw materials for glass batching, including batching calculation, weighing, mixing and other processes.

[0031] c. Put the glass batch material into a corundum crucible and melt it in a silicon-molybdenum furnace with a temperature range of 1600°C for 5 hours. The molten glass is cast into a plate shape in a hot graphite mold, and then placed in a muffl...

Embodiment 3

[0036] a. The oxidation composition of the basic glass is: SiO 2 (64wt%), Al 2 o 3 (18wt%), Li 2 O (3wt%), SrO (3wt%), MgO (3wt%), B 2 o 3 (1wt%), Na 2 O (0.5wt%), TiO 2 (2.5wt%), ZrO 2 (2wt%), Er 2 o 3 (2wt%), Bi 2 o 3 (0.5wt%), Co 2 o 3 (0.2wt%), Sb 2 o 3 (0.3 wt%). Correspondingly, the raw materials used are chemically pure chemical raw materials, corresponding to: silica, alumina powder, lithium carbonate, strontium carbonate, magnesium carbonate, boric acid, soda ash, titanium oxide, zirconia, erbium oxide, oxide Bismuth, cobalt trioxide and antimony trioxide.

[0037] b. Use the above-mentioned chemical raw materials for glass batching, including batching calculation, weighing, mixing and other processes.

[0038] c. Put the glass batch material into a corundum crucible and melt it in a silicon-molybdenum furnace with a temperature range of 1620°C for 6 hours. The molten glass is cast into a plate shape in a hot graphite mold, and then placed in a muffl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com