Sulfonate flame retardant with high nitrogen and phosphorus content, preparation method and application

A sulfonate and flame retardant technology, applied in the field of flame retardant synthesis, can solve the problems of easy-to-corrode molds, large amount of flame retardants, environmental hazards, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a preparation method of the above-mentioned high nitrogen-containing phosphorus-containing sulfonate flame retardant, comprising the following steps:

[0032] Step 1, using polycyanogen chloride as a matrix and sodium p-aminobenzenesulfonate as a nucleophile to synthesize compound II, said compound II has the following structure:

[0033]

[0034] Step 2, triphenylphosphine oxide is nitrated into compound III with a nitrating agent, and the compound III has the following structure:

[0035]

[0036] Step 3, the compound III is reduced to generate compound IV, and the compound IV has the following structure:

[0037]

[0038] Step 4, using the compound II as the matrix and the compound IV as the nucleophile to synthesize the compound I as the target product.

[0039] Concrete reaction process is as follows:

[0040]

[0041] Preferably, the specific process of said step 1 is: adding cyanuric chloride into a t...

Embodiment

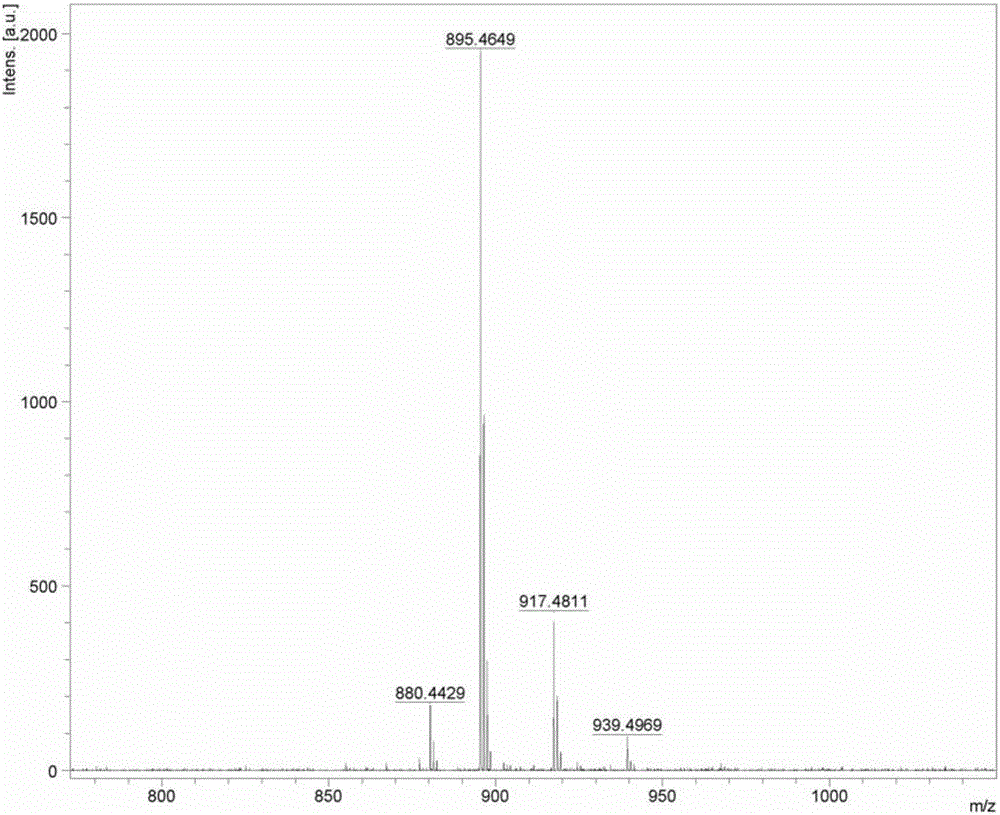

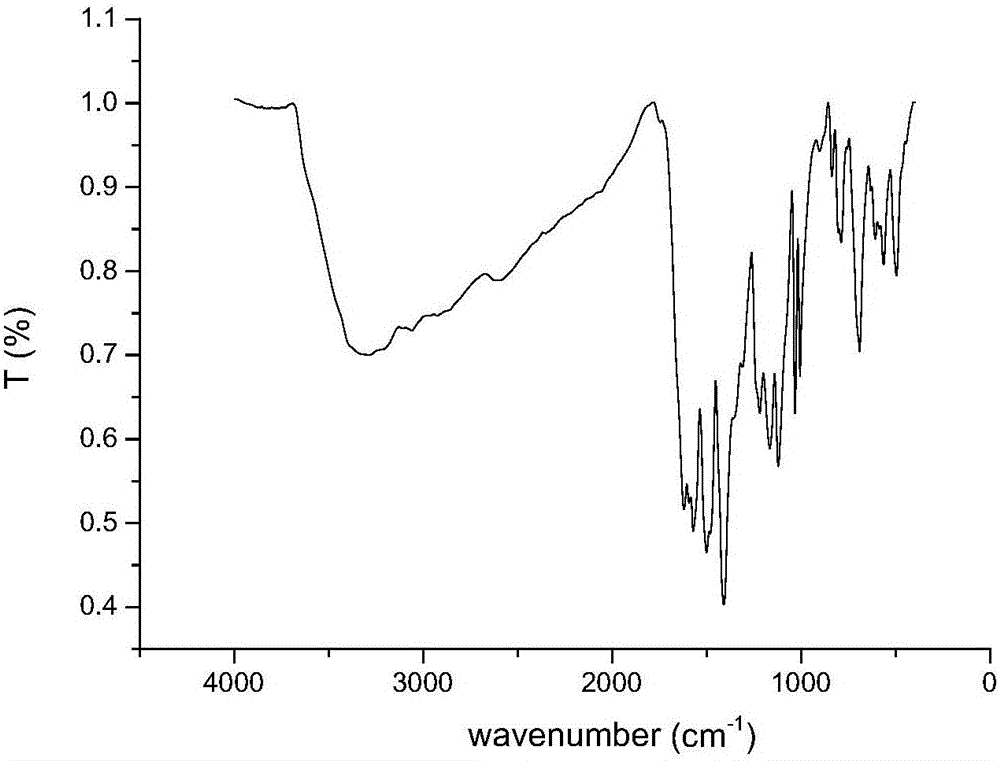

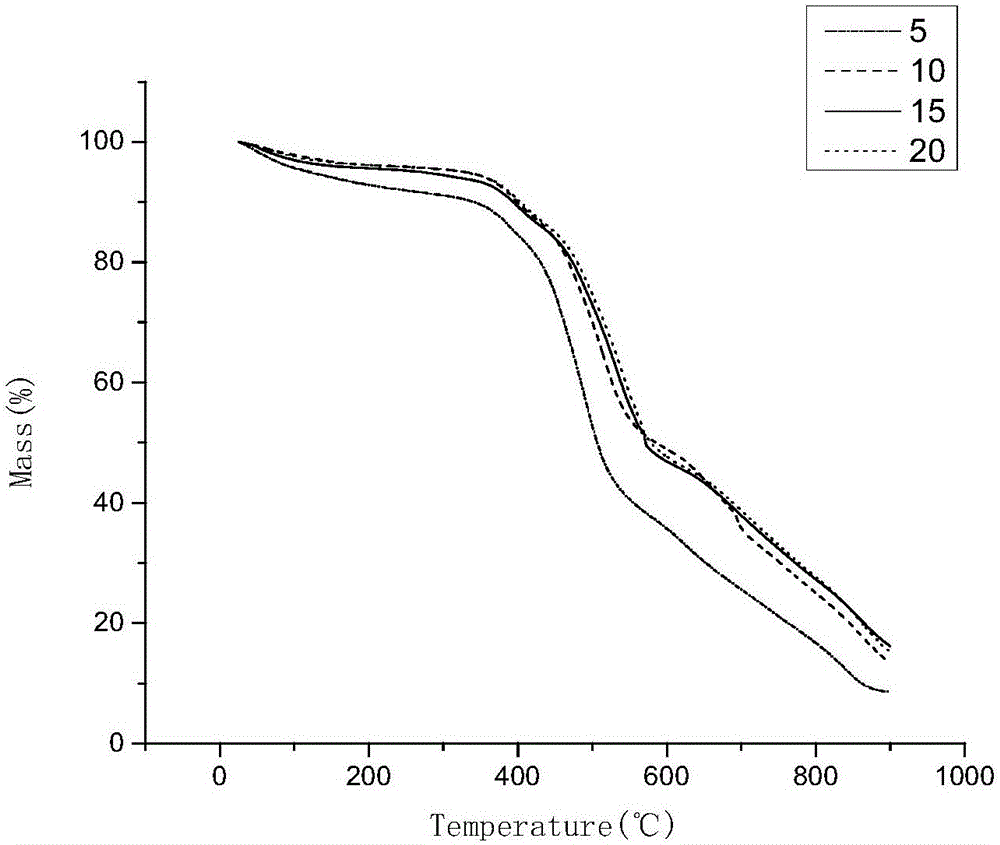

[0052]First, stir and dissolve 18.40g (0.1mol) of cyanuric chloride in a 1000ml four-neck flask in 300ml of industrial acetone, then place the aqueous solution containing 36.8g (0.1mol) of sodium p-aminobenzenesulfonate in a constant pressure dropping funnel , slowly drop into the four-neck flask. A large amount of white precipitate was produced during the reaction. During the reaction process, adjust the pH value with a sodium hydroxide solution with a concentration of 1 mol / L to about 7 to 8, and react for 2 hours. After the reaction is completed, filter under reduced pressure, take out the filter cake, and wash with industrial acetone (50mL×3) repeatedly. . Filter and dry. The developer was methanol:toluene=1:1, and dried to obtain compound II as a white solid.

[0053] 0.1 mol of triphenylphosphine oxide was stirred and dissolved in 400 ml of 95-98% concentrated sulfuric acid in a 1000 ml four-necked flask at -5°C to obtain a colorless transparent liquid. Nitrating age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com