Extracting method of citrus essential oil

An extraction method and a technology for citrus essential oil, which are applied in the directions of essential oils/spice, fat production, etc., can solve the problems of high operating pressure of supercritical extraction, difficulty in large-scale production, affecting the quality of essential oils, etc., and achieve excellent miscibility, short time, The effect of removing terpenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

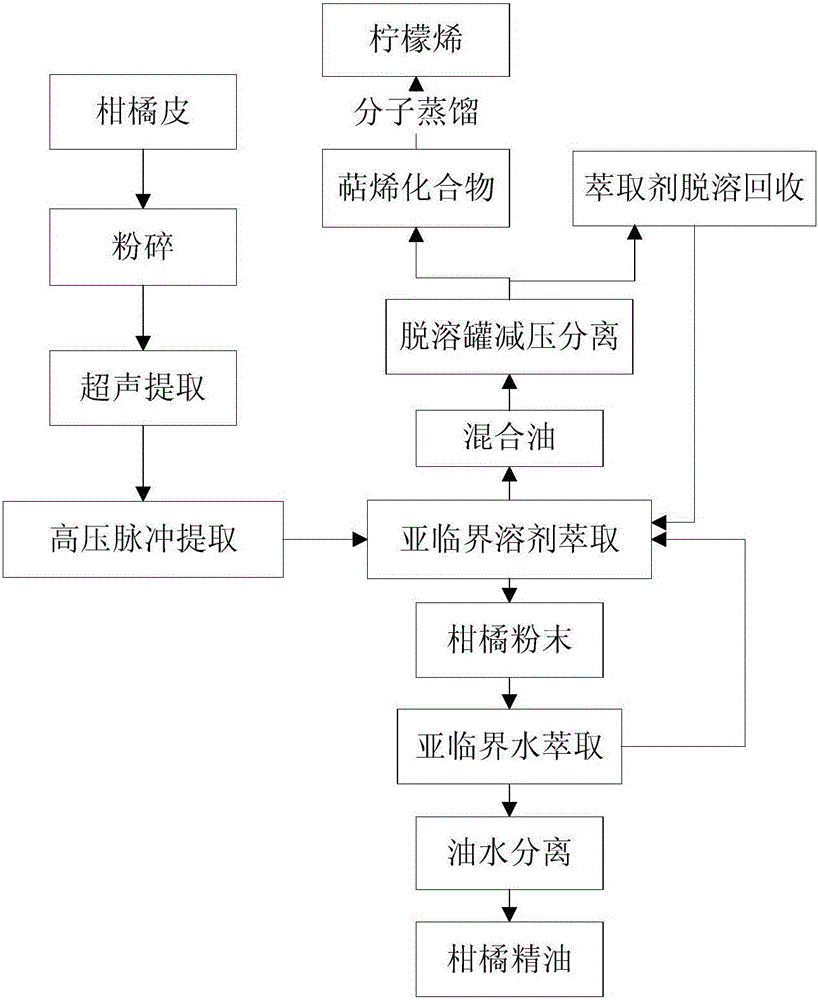

[0032] see figure 1 , a method for extracting citrus essential oil of the present invention, specifically comprising the steps of:

[0033] (1) Take 200 g of dried citrus peel, and use an ultrafine pulverizer to ultrafinely pulverize it at -10°C for 5 minutes to obtain a powder with a particle size of 2 mm.

[0034] (2) Place the powder of step (1) in the batching tank, add extractant by 1g: 15mL (extractant is a mixed solution of ethane and dimethyl ether, wherein the volume ratio of ethane and dimethyl ether is 8: 1 ), while slowly stirring, use a probe-type ultrasonic extractor to perform ultrasonic extraction for 15 minutes under the condition of a current intensity of 1.2A / 45w to obtain an ultrasonic extract.

[0035] (3) Place the ultrasonic extract in step (2) in a high-voltage pulsed electric field, set the electric field strength to 25KV / cm, pulse time to 500μs, pulse frequency to 240Hz, and extract for 20min to obtain a high-voltage pulsed extract.

[0036] (4) Tak...

Embodiment 2

[0041] see figure 1 , a kind of extracting method of citrus essential oil of the present invention, comprises the steps:

[0042] (1) Take 200 g of dried citrus peel, and use an ultrafine pulverizer to ultrafinely pulverize it at -10°C for 5 minutes to obtain a powder with a particle size of 2 mm.

[0043] (2) Place the powder of step (1) in the batching tank, add extractant by 1g:10mL (extractant is a mixed solution of ethane and dimethyl ether, wherein the volume ratio of ethane and dimethyl ether is 8:1 ), while slowly stirring, use a probe-type ultrasonic extractor to perform ultrasonic extraction for 10 minutes under the condition of current intensity 1A / 25w to obtain an ultrasonic extract.

[0044](3) Place the ultrasonic extract in step (2) in a high-voltage pulsed electric field, set the electric field strength to 25KV / cm, pulse time to 500μs, pulse frequency to 240Hz, and extraction time to 20min to obtain a high-voltage pulsed extract.

[0045] (4) Take 3L of the h...

Embodiment 3

[0050] see figure 1 , a kind of extracting method of citrus essential oil of the present invention, comprises the steps:

[0051] (1) Take 200 g of dried citrus peel, and use an ultrafine pulverizer to ultrafinely pulverize it at -10°C for 5 minutes to obtain a powder with a particle size of 2 mm.

[0052] (2) Place the powder of step (1) in the 5L leaching tank of the subcritical extraction complete set of equipment, add the extractant by 1g: 10mL (the extractant is a mixed solution of ethane and dimethyl ether, wherein ethane and dimethyl ether Ether volume ratio is 8:1), infiltrated for 3 hours; then subcritical solvent extraction was carried out under the conditions of extraction pressure of 15Mpa, extraction temperature of 40°C and extraction of 30min to obtain mixed oil and citrus powder.

[0053] (3) Take the mixed oil in step (2) and import it into the desolventization tank, reduce the pressure to -0.08MPa to carry out decompression separation in the desolventization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com