Super-elasticity low-elastic-modulus titanium alloy material and preparation method and application thereof

A low elastic modulus, alloy material technology, applied in superelastic low elastic modulus titanium alloy material and its preparation, superelastic low elastic modulus Ti-Nb-Zr-O alloy material and its preparation field, can solve alloy critical Problems such as low slip stress and low superelasticity achieve the effect of reducing the difficulty of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of Ti-18Nb-10Zr-0.5O alloy material

[0022] (1) Ti-18Nb-10Zr-0.5O alloy, the raw materials are 0-grade sponge Ti, firearms-grade sponge Zr, Ti-45Nb master alloy, TiO 2 The powder is batched according to the composition ratio, smelted in a non-consumable vacuum electric arc furnace, fully stirred, and the number of smelting is 3 to 5 times to obtain Ti-18Nb-10Zr-0.5O ingot;

[0023] (2) The Ti-18Nb-10Zr-0.5O alloy obtained above was subjected to wire cutting, put into a heat treatment furnace for heat treatment, and then water quenched after the heat treatment temperature was kept at 850°C for 1 hour.

[0024] (3) cold rolling the alloy after solution treatment, with a deformation amount of 90%, in the air; Ti-18Nb-10Zr-0.5O plate can be obtained;

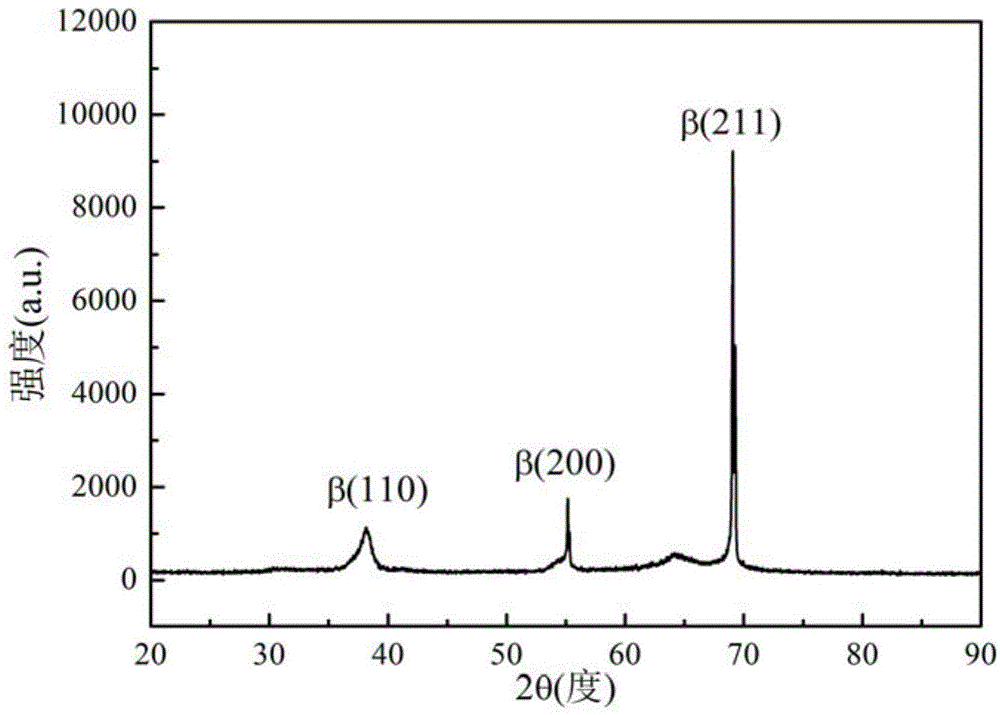

[0025] (4) The cold-rolled sheet is annealed at 600°C for 0.5h, and air-cooled to obtain a complete β-phase structure.

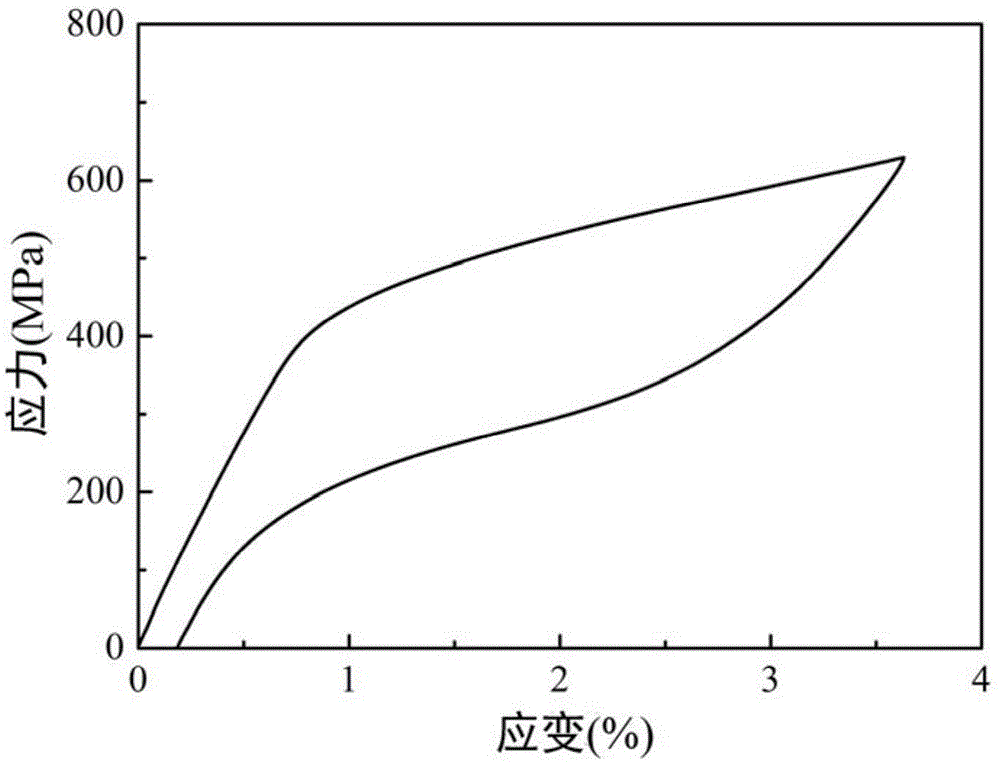

[0026] Material properties: room temperature superelasticity 2.5%, elastic mod...

Embodiment 2

[0027] Example 2: Preparation of Ti-18Nb-10Zr-1.5O alloy material

[0028] (1) Ti-18Nb-10Zr-1.5O alloy, raw materials are 0 grade sponge Ti, firearms grade sponge Zr, Ti-45Nb master alloy, TiO 2 The powder is batched according to the composition ratio, melted in a non-consumable vacuum electric arc furnace, fully stirred, and the number of melting times is 3 to 5 times to obtain Ti-18Nb-10Zr-1.5O ingot;

[0029] (2) The Ti-18Nb-10Zr-1.5O alloy obtained above was subjected to wire cutting, put into a heat treatment furnace for heat treatment, and was kept at 850° C. for 1.5 hours, then water quenched.

[0030] (3) cold rolling the alloy after solution treatment, with a deformation amount of 80%, in the air; Ti-18Nb-10Zr-1.5O plate can be obtained;

[0031] (4) The cold-rolled sheet is annealed at 580°C for 1 hour, and air-cooled to obtain a complete β-phase structure.

[0032] Material properties: room temperature superelasticity 3%, elastic modulus 58GPa, elongation 10%.

Embodiment 3

[0033] Example 3: Preparation of Ti-18Nb-13Zr-0.5O alloy material

[0034] (1) Ti-18Nb-13Zr-0.5O alloy, the raw materials are 0-grade sponge Ti, firearms-grade sponge Zr, Ti-45Nb master alloy, TiO 2 The powder is batched according to the composition ratio, smelted in a non-consumable vacuum electric arc furnace, fully stirred, and the number of smelting times is 3 to 5 times to obtain Ti-18Nb-13Zr-0.5O ingot;

[0035] (2) Carry out wire cutting of the Ti-18Nb-13Zr-0.5O alloy prepared above, put it into a heat treatment furnace for heat treatment, keep it at 800° C. for 1.5 hours, and then quench it in water.

[0036] (3) cold rolling the alloy after solution treatment, with a deformation amount of 85%, in air; Ti-18Nb-13Zr-0.5O plate can be obtained;

[0037] (4) Anneal the cold-rolled sheet at 500°C for 0.5h, and air-cool to obtain a complete β-phase structure.

[0038] Material properties: room temperature superelasticity 3.3%, elastic modulus 53GPa, elongation 20%.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com