Compound rice field herbicide

A compound herbicide and paddy field technology, which is applied in the field of pesticides, can solve the problems of wasting manpower and material resources, and achieve the effects of saving labor costs, reducing the amount of pesticides, and having a good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

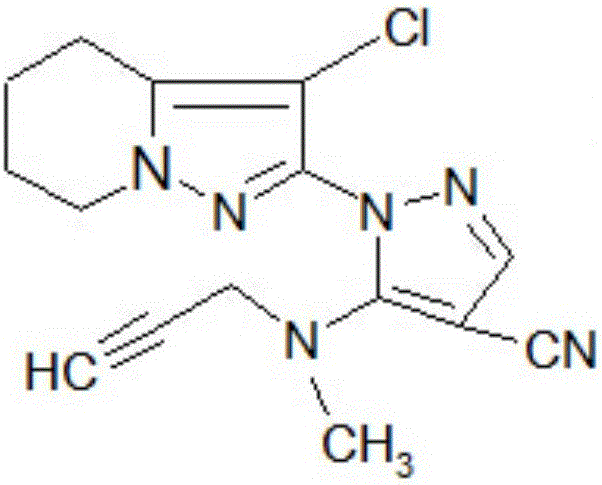

Image

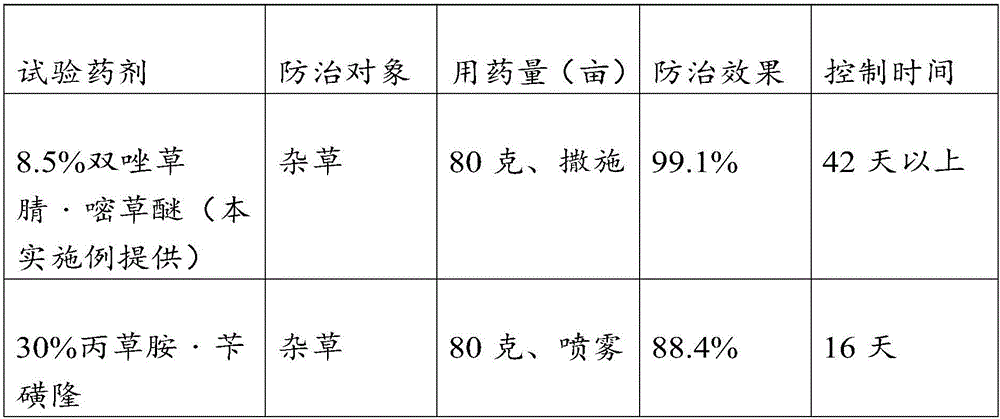

Examples

Embodiment 1

[0043] The paddy field compound herbicide provided in this example is a wettable powder (WP), which is mainly made of the following raw materials: 7% pyrimifluben, 1.5% pyrifluconate, lignosulfonic acid 6% of salt, 2% of calcium dodecylbenzenesulfonate, 1.5% of carboxymethyl cellulose and 82% of filler, the filler is a mixture of 2% of white carbon black and 80% of kaolin. Wherein, lignosulfonate is used as a dispersant, calcium dodecylbenzenesulfonate is used as a wetting agent, and carboxymethyl cellulose is used as a binder.

[0044] The paddy field compound herbicide provided in this example is prepared by the following process: first add half of the filler into the mixer, add the weighed dipacenil and pyrimethanil, and mix evenly, and then add the lignin Sulfonate, calcium dodecylbenzenesulfonate, carboxymethyl cellulose and the remaining fillers are added together, mixed evenly to obtain a mixture, and then crushed by airflow until 99% of the mixture can pass through a 3...

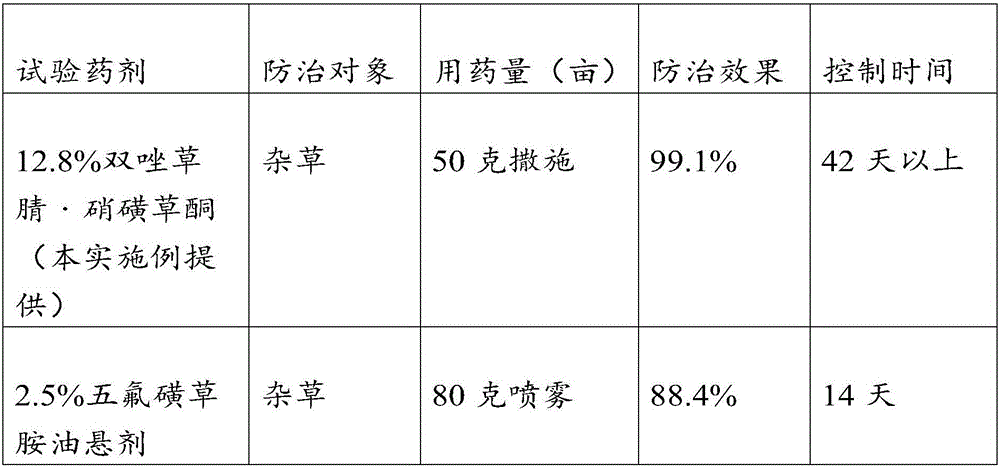

Embodiment 2

[0050] The paddy field compound herbicide provided in this example is a large-grained paddy field compound herbicide, which is mainly made of the following raw materials: 12% of fenpyrafen, 0.8% of mesotrione, and 8% of lignosulfonate , Sodium dodecylbenzene sulfonate 3%, 500# agricultural milk 3%, porous perlite 73.2%. Among them, lignosulfonate is used as a dispersant, calcium dodecylbenzenesulfonate is used as a wetting agent, and porous perlite is used as an adsorbent.

[0051] The paddy field compound herbicide provided in this example is formulated through the following process: mixing dipacenil, mesotrione, lignin sulfonate, calcium dodecylbenzene sulfonate and 500# agricultural milk together uniform, then add the prepared porous perlite, mix to obtain a mixed material, transfer the mixed material to a kneader for kneading, extrude and granulate through an extrusion granulator, and then use a fluidized bed to dry, granulate, After sieving, the large-grain finished prod...

Embodiment 3

[0057] The paddy field composite herbicide provided by the present embodiment is a microemulsion (ME), which is mainly made of the following raw materials: bisacenil 9%, trifentrazone 9%, styrene ( Methyl styrene) phenol polyoxyethylene polyoxypropylene ether 6%, styrene ethylphenol polyoxyethylene ether 8%, cyclohexanone 6%, n-butanol 4%, water 58%. Wherein, styrene (methylstyrene) phenol polyoxyethylene polyoxypropylene ether and styrene ethylphenol polyoxyethylene ether are used as emulsifiers, and cyclohexanone, n-butanol and water are used as solvents.

[0058] The paddy field compound herbicide provided in this example is formulated by the following process: after mixing bisacenil and flumezone-sulam, dissolve in a solvent composed of cyclohexanone and n-butanol, and then add styrene (Methylstyrene) phenol polyoxyethylene polyoxypropylene ether and styrene ethylphenol polyoxyethylene ether, mix evenly, stir and slowly pour into water at the same time, after W / O phase inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com