Shipborne spilled-oil recycling system based on gas floating spilled oil separation

An oil spill recovery and air flotation technology, which is applied in the direction of liquid separation, separation method, flotation water/sewage treatment, etc., can solve the problems of increasing the number of round trips of ships, increasing the water content of recovered oil spills, and unfavorable rapid recovery of oil spills, etc. problems, to achieve the effect of reducing the number of round trips, improving oil recovery efficiency, and rapid and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

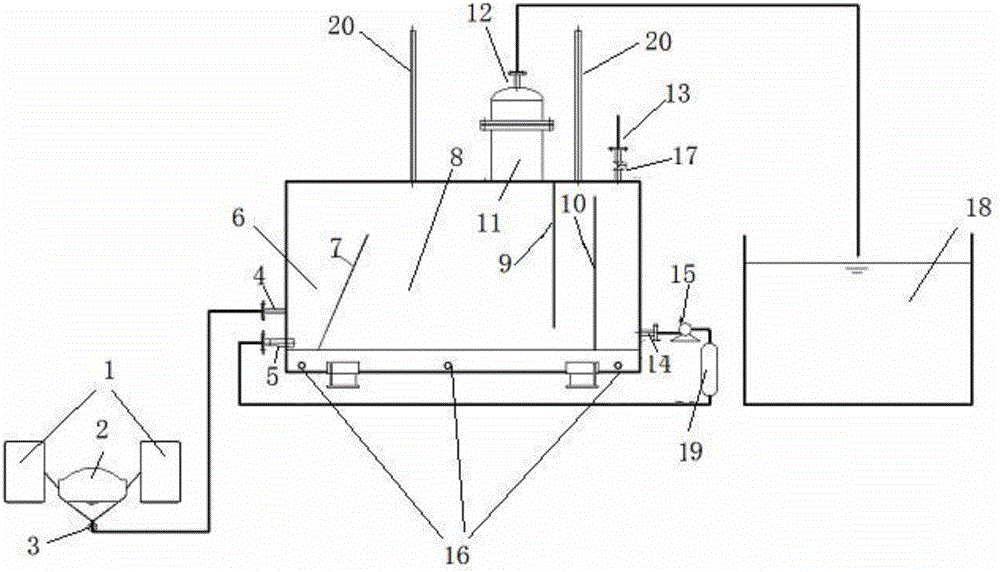

[0019] A shipborne oil spill recovery system based on air flotation oil spill separation, including an oil skimmer, an oil-water separation unit, an air flotation unit, and a dirty oil tank 18; the air flotation unit includes a buoy 1 and an air flotation contact area 6, and the oil skimmer An overflow weir adjustment plate 2 is provided, and the oil-water separation unit includes an oil-water separation area 8. The front end of the oil-water separation unit is provided with a water inlet pipe interface 4, and the water inlet pipe interface 4 is connected to the oil skimmer; the air flotation release port 5 is connected to the multiphase medium pump The outlet of 15 is connected; the air flotation contact zone 6 and the oil-water separation zone 8 are separated by a slant plate 7, the middle and rear sections of the oil-water separation unit are provided with an oil separator 9 and a water separation plate 10, and the rear part of the oil-water separation unit is provided with m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com