Method for curing sludge for roadbed filling

A technology of roadbed and sludge, applied in the field of resources and environment, can solve the problems of environmental burden and waste of resources, reduce the stability of sludge solidified soil, and have no guarantee of long-term stability, achieve strong acid resistance and alkali resistance, inhibit Bacterial growth and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

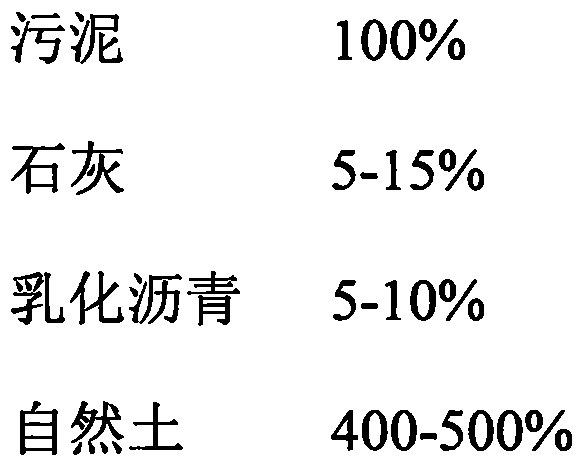

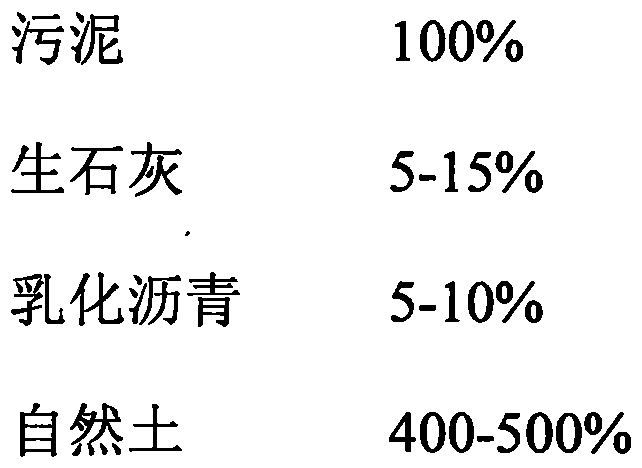

[0020] Take 100kg of dewatered sludge from urban sewage plants with a moisture content of 80%, first add 10kg of quicklime, stir evenly, then add 5kg of emulsified asphalt, and carry out the second stirring, then add 500kg of natural soil after stirring evenly, and carry out the second Stir three times. Finally, the sludge-solidified soil was placed in a curing field, and after 7 days of dry curing, the compressive strength of the sludge-solidified soil reached 1000kPa. The results of toxicity leaching tests show that the detected amounts of various heavy metals and organic matter do not exceed the standard, which can meet the requirements of roadbed filling.

Embodiment 2

[0022] Take 100kg of dewatered sludge from urban sewage plants with a water content of 80%, first add 15kg of quicklime, stir evenly, then add 8kg of emulsified asphalt, and carry out the second stirring, then add 400kg of natural soil after stirring evenly, and carry out the second Stir three times. Finally, the sludge-solidified soil is placed in the curing field. After 7 days of dry curing, the compressive strength of the sludge-solidified soil reaches 900kPa, which can meet the requirements of roadbed filling. The results of toxicity leaching tests show that the detected amounts of various heavy metals and organic matter do not exceed the standard, which can meet the requirements of roadbed filling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com