A kind of water-resistant inorganic coating and preparation method thereof

A technology of inorganic coatings and raw materials, applied in the direction of alkali metal silicate coatings and coatings, etc., can solve the problems of easy bubbles in exterior wall coatings, rain wash on exterior walls, mottled exterior walls, etc., and achieve long-term bright and new walls. The effect of good adhesion and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

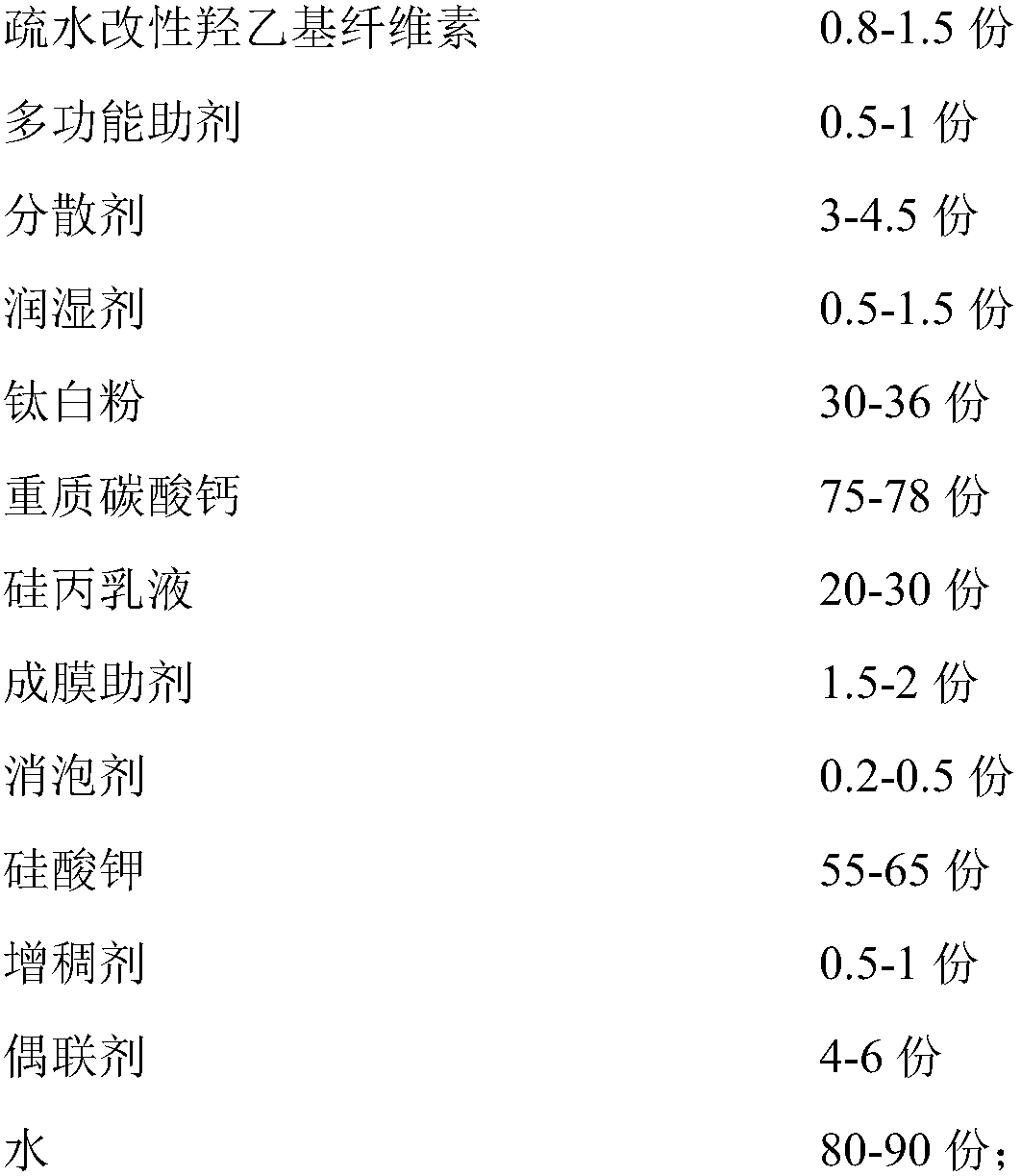

[0062] A water-resistant inorganic coating mainly consists of the following raw materials in parts by weight:

[0063] Hydrophobically modified hydroxyethyl cellulose 0.3 parts

[0064] 2 parts multifunctional additive

[0065] Dispersant 2.5 parts

[0066] Wetting agent 2 parts

[0067] Titanium dioxide 25 parts

[0068] 80 parts of heavy calcium carbonate

[0069] Silicone acrylic emulsion 20 parts

[0070] Coalescing aid 2.5 parts

[0071] 0.2 parts of defoamer

[0072] Potassium silicate 75 parts

[0073] Thickener 0.5 parts

[0074] 6 parts of coupling agent

[0075] 80 parts of water.

[0076] The dispersant is a mixture of ammonium salt dispersant and silicate dispersant, and the mixing weight ratio is 1:1.5.

[0077] The thickener is a polyurethane thickener.

[0078] The multifunctional additive is selected from Angus AMP-95.

[0079] The coupling agent is a silane coupling agent.

[0080] The viscosity of the hydrophobically modified hydroxyethyl cellul...

Embodiment 2

[0089] A water-resistant inorganic coating mainly consists of the following raw materials in parts by weight:

[0090] Hydrophobically modified hydroxyethyl cellulose 1.8 parts

[0091] 0.5 parts of multifunctional additive

[0092] Dispersant 5.5 parts

[0093] Wetting agent 0.5 parts

[0094] Titanium dioxide 36 parts

[0095] 75 parts of heavy calcium carbonate

[0096] Silicone acrylic emulsion 40 parts

[0097] Coalescing aid 1.5 parts

[0098] 0.8 parts of defoamer

[0099] Potassium silicate 55 parts

[0100] thickener 2 parts

[0101] 4 parts of coupling agent

[0102] 80 parts of water.

[0103] The dispersant is a mixture of ammonium salt dispersant and silicate dispersant, and the mixing weight ratio is 3:2.5.

[0104] The thickener is a polyurethane thickener.

[0105] The multifunctional additive is purchased from Deqian MA-95.

[0106] The coupling agent is a silane coupling agent.

[0107] The viscosity of the hydrophobically modified hydroxyethyl ...

Embodiment 3

[0116] A water-resistant inorganic coating mainly consists of the following raw materials in parts by weight:

[0117] Hydrophobically modified hydroxyethyl cellulose 1 part

[0118] 1 multifunctional additive

[0119] Dispersant 3.5 parts

[0120] Wetting agent 1.5 parts

[0121] Titanium dioxide 30 parts

[0122] 78 parts of heavy calcium carbonate

[0123] Silicone acrylic emulsion 30 parts

[0124] Coalescing aid 2 parts

[0125] 0.5 parts of defoamer

[0126] Potassium silicate 65 parts

[0127] Thickener 1.5 parts

[0128] 5 parts of coupling agent

[0129] 85 parts of water.

[0130] The dispersant is a mixture of ammonium salt dispersant and silicate dispersant with a mixing weight ratio of 2:1.5.

[0131] The thickener is a polyurethane thickener.

[0132] The multifunctional additive is selected from Angus AMP-95.

[0133] The coupling agent is a silane coupling agent.

[0134] The viscosity of the hydrophobically modified hydroxyethyl cellulose is 3000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com