Micro-fluidic chip and nucleic acid extraction and purification method therewith

A technology of a microfluidic chip and a purification method, which is applied in the field of microfluidic chip and nucleic acid extraction and purification using the microfluidic chip, can solve the problems of environmental pollution, time-consuming and cumbersome, and inflexible operation, and achieves the realization of spatial and temporal resolution information. , Avoid manual operation, optimize the effect of purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

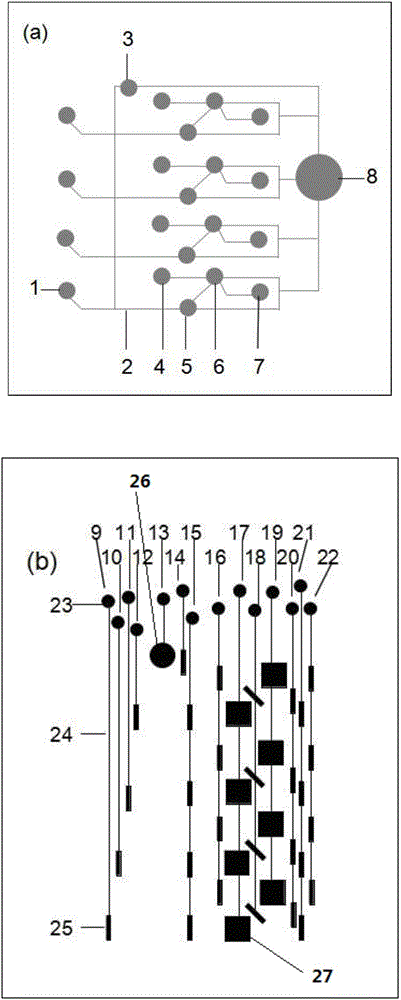

[0064] Extraction and purification of lambda DNA

[0065] separately to figure 1 Add 6ng / μL λDNA solution into the sample pool 4 of the chip shown, and add superparamagnetic silicon beads, loading buffer, washing solution and eluent into inlet 1. Under the control of the pneumatic microvalve, the λDNA and superparamagnetic silicon beads The sample buffer, cleaning solution and eluent enter the mixing unit under the condition of vacuum driving force, and the pneumatic microvalve is also controlled to realize the sufficient mixing and purification of the nucleic acid extraction buffer and λDNA, and the sample buffer, cleaning solution and washing solution are collected respectively. dehydration.

[0066] Specific steps include:

[0067] 1. Fully mix the sample solution containing λDNA with superparamagnetic nanoparticles. Under the acidic condition of pH 6.1, the nucleic acid and superparamagnetic nanoparticles combine to form nucleic acid-magnetic nanoparticle complexes and a...

Embodiment 2

[0070] Extraction and purification of real sample DNA

[0071] separately to figure 1 Cell lysates (eukaryotic cells or prokaryotic cells) are respectively added to the sample pool 4 of the chip shown, and superparamagnetic silica beads, sample loading buffer, washing solution and eluent are added to the inlet 1, and controlled by a pneumatic microvalve, The real sample, superparamagnetic silica beads, loading buffer, cleaning solution and eluent enter the mixing unit under the condition of vacuum driving force, and the pneumatic microvalve is also controlled to realize the full mixing of nucleic acid extraction buffer and lysed cell buffer, Purify, and finally collect the eluate containing the purified DNA sample. The specific steps include: 1. Fully mixing the lysed cell solution with the superparamagnetic nanoparticles, and under the acidic condition of pH 6.1, the nucleic acid and the superparamagnetic nanoparticles combine to form a nucleic acid-magnetic nanoparticle com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com