Method for improving yield of echimocandins B

A technology for echinocandin and yield is applied in the field of cultivation for increasing the yield of aniduckin precursor compound EchinocandinB, and can solve the problems of low fermentation yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

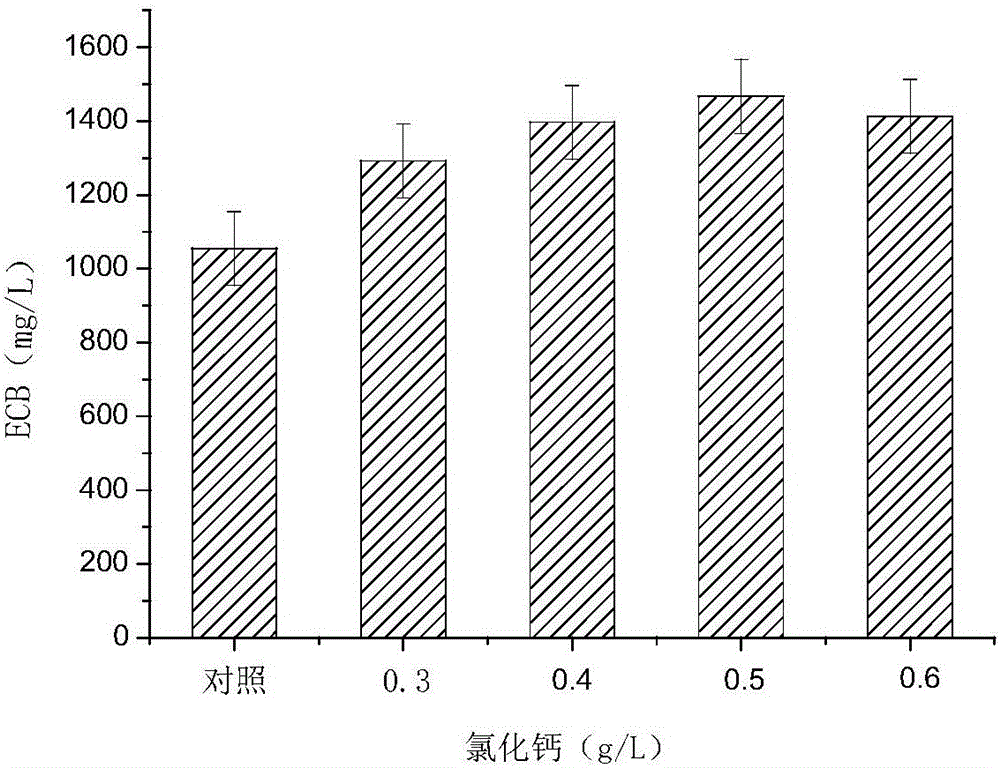

[0028]Embodiment 1: the influence of adding calcium chloride on the output of echinocandin B in the fermentation medium;

[0029] (1) Slant culture: inoculate Aspergillus nidulans ZJB09223 into the slant medium, culture at 25-30°C for 28 hours, and obtain slant bacteria; the final concentration of the slant medium used is composed of: potatoes 200g / L (boiled supernatant), Sucrose 20g / L, agar powder 20g / L, pH natural, solvent is water, sterilized at 121°C for 20min and cooled before use;

[0030] (2) Seed culture: inoculate the slanted bacteria from step (1) into the seed medium, cultivate at 25-30°C for 48 hours, and obtain the seed liquid; the final concentration of the seed medium consists of: cottonseed powder 25g / L, glucose 10g / L, Glycerin 10g / L, pH 6.8-7.0, solvent is distilled water, sterilized at 115°C for 30 minutes and cooled before use.

[0031] (3) Fermentation culture: step (2) seed liquid is respectively inoculated to add 0g / L, 0.3g / L, 0.4g / L, 0.5g / L, 0.6g / L fina...

Embodiment 2

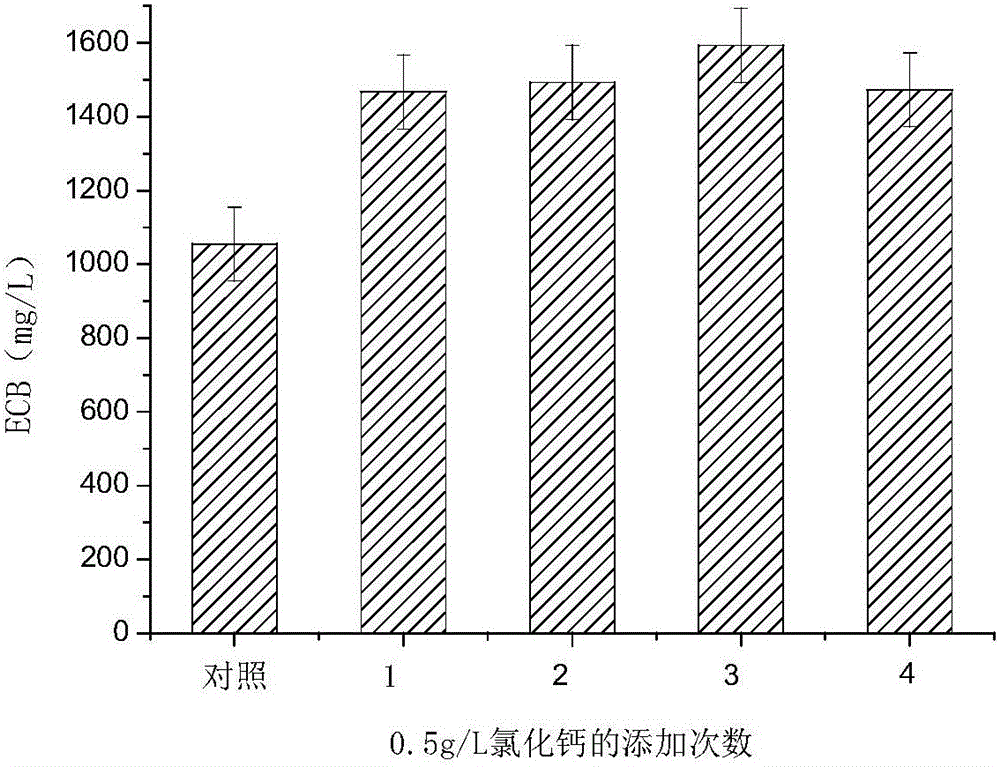

[0049] Example 2: Effects of different addition times of calcium chloride with a final concentration of 0.5g / L in the fermentation medium on the yield of echinocandin B

[0050] Slope culture and seed culture are the same as in Example 1.

[0051] Fermentation culture: inoculate the seed solution to the fermentation medium with an inoculation amount of 10% volume concentration, set up 1 control group (the control group does not add calcium chloride) and 4 experimental groups (group 1-group 4), group 1 - Group 4 added calcium chloride in 1, 2, 3, and 4 times respectively, starting from the initial time 0h, and adding once every 8h (group 1 (that is, the 1-time addition group) added calcium chloride at a concentration of 5g / L , Group 2 (i.e. 2 times of addition group) added calcium chloride concentration of 2.5g / L each time, group 3 (i.e. 3 times of addition group) added calcium chloride concentration of 1.67g / L each time, group 4 (i.e. 4 Second addition group) each addition of...

Embodiment 3

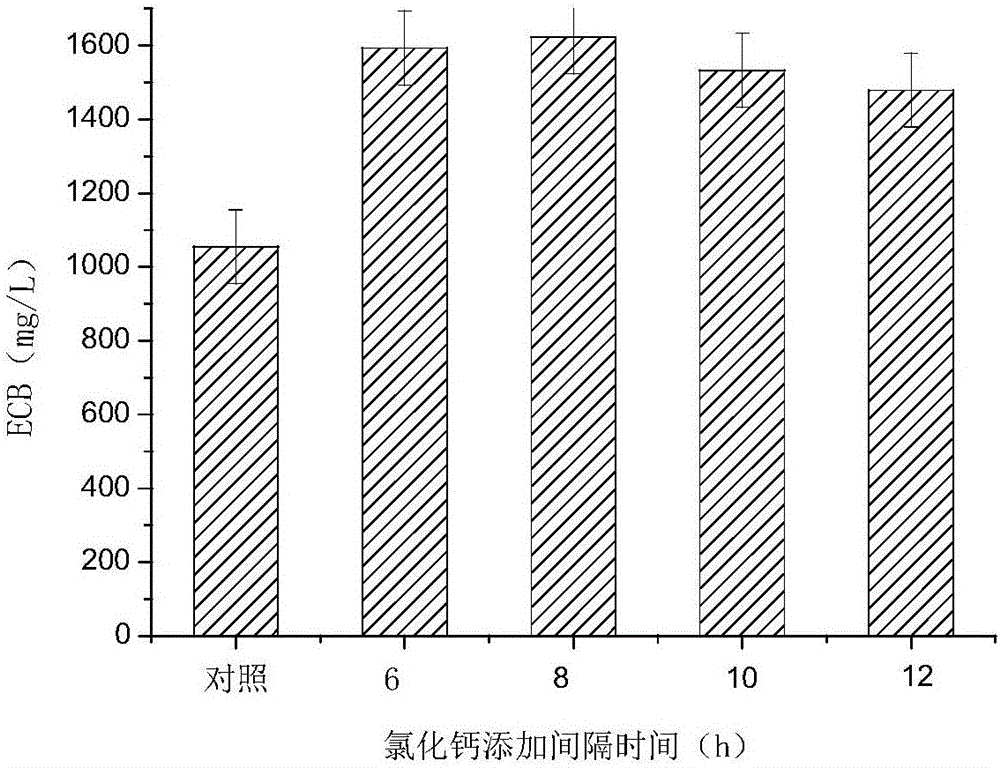

[0053] Example 3: Effects of different addition intervals of calcium chloride with a final concentration of 0.5g / L in the fermentation medium on the yield of echinocandin B

[0054] Slope culture and seed culture are the same as in Example 1.

[0055] Fermentation culture: inoculate the seed solution to the fermentation medium with an inoculation amount of 10% volume concentration, set up 1 control group (the control group does not add calcium chloride) and 4 experimental groups (group 1-group 4), group 1 - Group 4 added calcium chloride once at the beginning of fermentation 0h, and then added calcium chloride once at intervals of 6h, 8h, 10h, and 12h, with a concentration of 0.167g / L each time, until the final concentration of calcium chloride was 0.5g / L, cultured at 20-30°C, 220-280rpm for 12 days to obtain a fermentation broth, and no addition of metal ions was used as a control. The content of echinocandin B in the fermentation broth was detected by HPLC method, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com