Single-grade direct-driven boost centrifugal air compressor of vehicle fuel cell engine

A technology for centrifugal air compressors and fuel cells, which is applied in liquid fuel engines, machines/engines, electric components, etc., and can solve the problems of rotor surface wind wear loss, bearing and other support components damage, and increase the difficulty of fault monitoring and diagnosis, etc. , to achieve the effect of improving performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

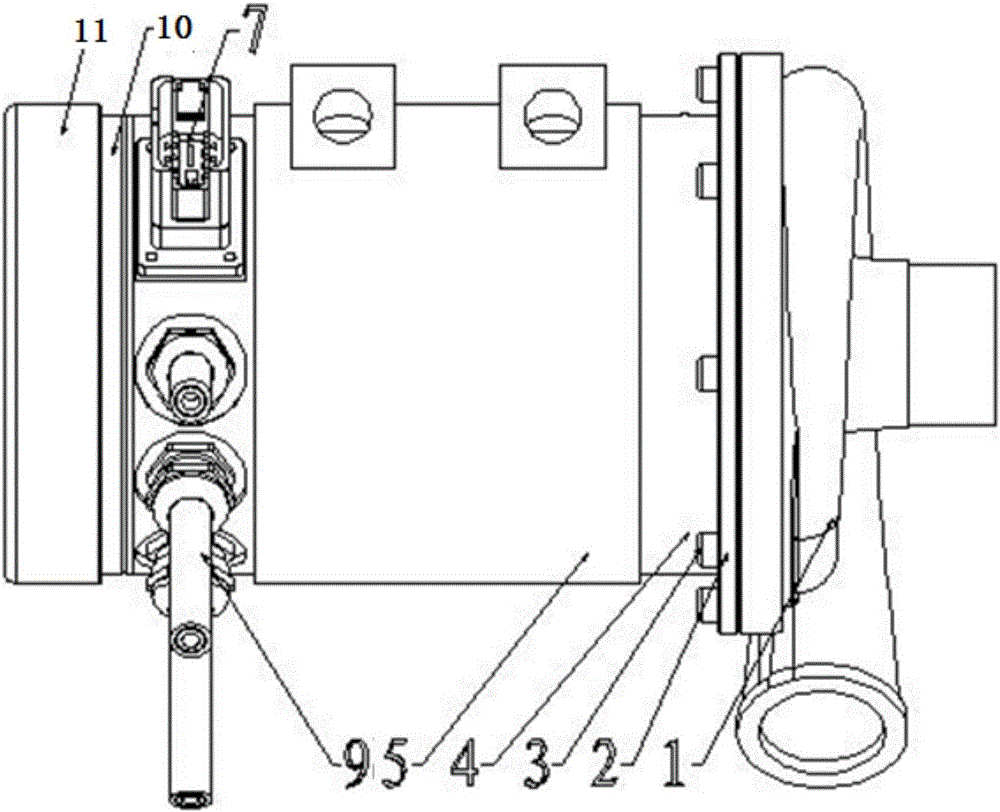

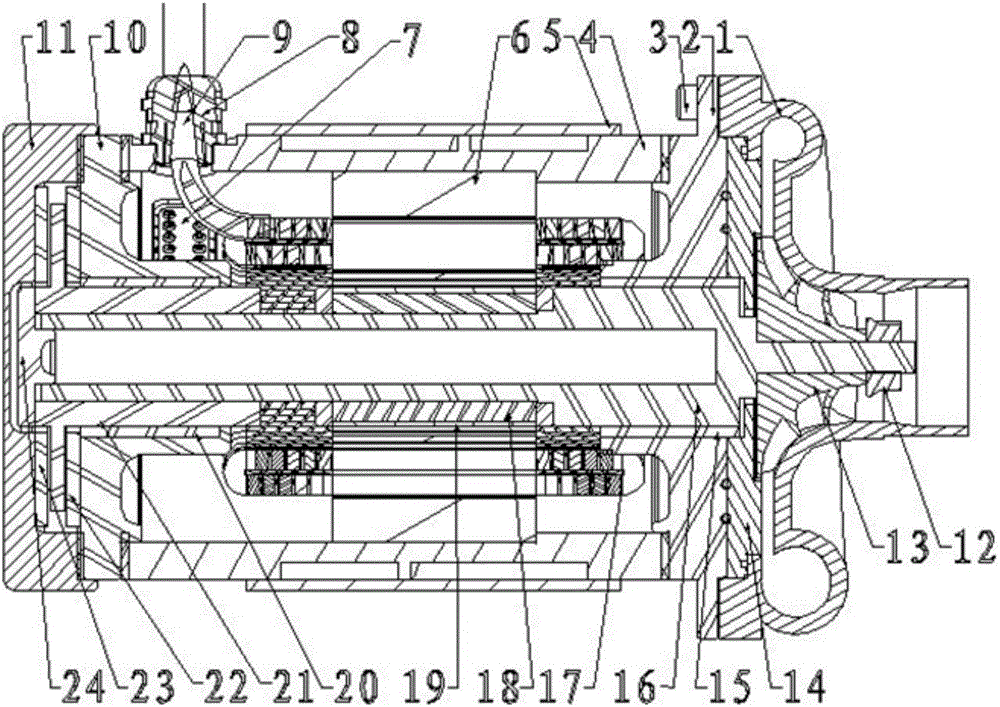

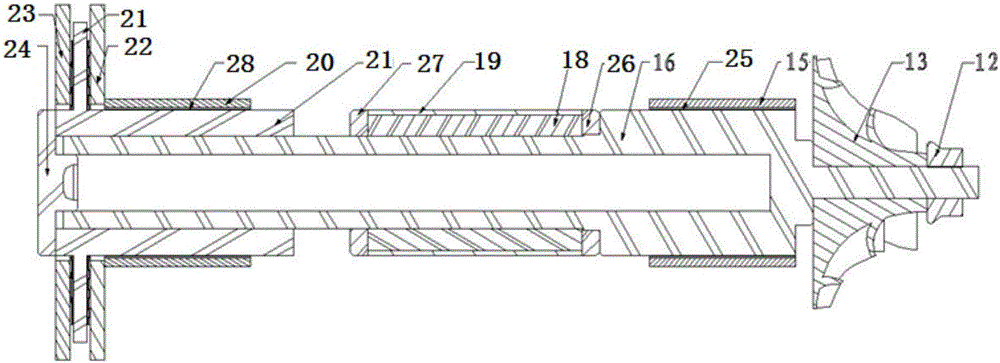

[0030] A single-stage turbocharged centrifugal air compressor for a vehicle fuel cell engine, the structure of which is as follows figure 1 and figure 2 As shown, the air compressor is connected with the motor and driven by the motor to rotate. The air compressor includes a main shaft 16, a rotor 18 fixed in the middle of the main shaft 16, a motor stator 6, a volute 1 and one end of the main shaft 16 arranged inside the volute 1. The connected impeller 13, the volute 1 is connected with the right end motor end cover 2, and fixed by the connecting bolt 3, the impeller 13 is fixed with the main shaft by the pre-tightening nut 12, and is bonded with high-strength glue to ensure the safety of the impeller at high speed Motor windings 17 are provided on both sides of the motor stator 6, and the motor windings 17 are connected to the motor through a three-phase cable 9 and a low-voltage signal connector 7, and a metal waterproof joint 8 is provided on the three-phase cable 9. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com