Small and medium sized environment-friendly biomass water heater

A biomass and water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of direct combustion of biomass fuels, high NOx emissions, and large air supply at the bottom, and reduce the supply of air. The air volume, the temperature in the furnace are uniform, and the effect of reducing the precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

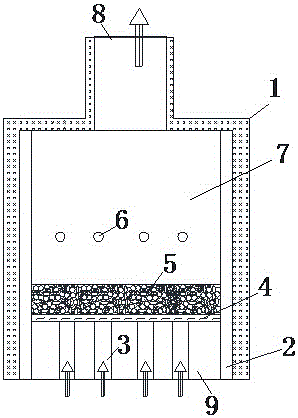

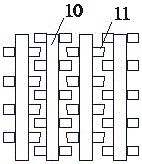

[0018] like figure 1 , shown in 2, the small and medium-sized environment-friendly biomass hot water heater of the present invention comprises a furnace body, an insulating material 1, a water-cooled pipe 2, a bottom air duct 3, a fire grate 4, a biomass fuel layer 5, a combustion tuyere 6, an upper combustion Chamber 7, combustion chamber outlet 8 and bottom ash tank 9, grate rod 10, slag breaking thorn 11.

[0019] The outside of the furnace body is provided with insulation material 1, and the bottom of the furnace is provided with a bottom ash tank 9 and a bottom air duct 3, and a fire grate 4 is arranged on the bottom ash tank 9 and the bottom air duct 3, and a biomass fuel layer 5 is placed on the fire grate 4 The upper combustion chamber 7 above the biomass fuel layer 5 is provided with a combustion tuyere 6 , and the upper combustion cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com