Photoetching machine projection objective and objective support through-hole design method

A technology of projection objective lens and lithography machine, which is applied in the field of lithography machine, can solve problems such as increased temperature sensitivity, easy pollution, and influence on lithography quality, so as to improve heat dissipation performance, reduce sensitivity, and improve lithography quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

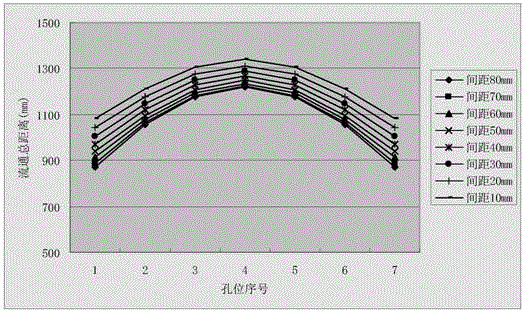

[0038] Embodiment 1, with θ=30, R=100, D=10, 20, 30, 40, 50, 60, 70, 80, the relationship between the total circulation distance L of each hole position and the lens distance D is obtained as follows Figure 5 shown.

Embodiment 2

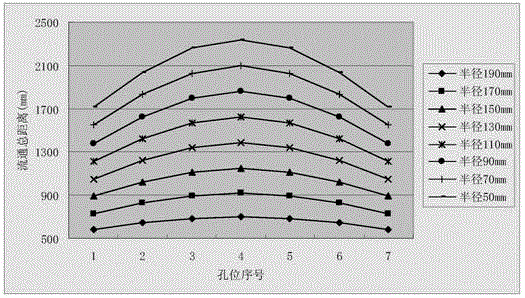

[0039] Embodiment 2, with θ=30, D=50, R=50, 70, 90, 110, 130, 150, 170, 190, the relationship between the total flow distance L of each hole position and the lens radius R is obtained as follows Image 6 shown.

[0040] Combining Embodiment 1 and Embodiment 2, it can be seen that,

[0041] 1. When the lens spacing D changes, the ratio of the total flow distance L of each hole hardly changes, but the radius of the lens changes, and the ratio of the total flow distance L of each hole changes, and the ratio becomes larger with the increase of the radius.

[0042] 2. The air hole 314 at the far end has the longest total flow distance L, and therefore the diameter d of the air hole 314 is the largest.

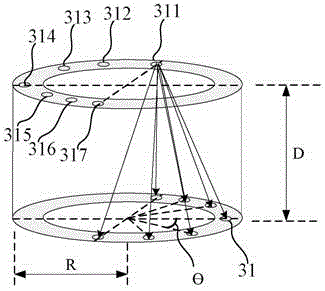

[0043] Therefore, the final via 31 distribution is as Figure 7 As shown, it should be noted that in the same projection objective, the distance D between the lenses 2 is different, and the radius R of the lens holder 3 is the same. For different projection objectives, the radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com