Power cable for 0.6/1kv and lower voltage

A low-voltage power and cable technology, which is applied in the direction of power cables, power cables including electric control, power cables including electrical communication lines, etc., can solve the problems affecting the use and promotion of fireproof cables, the end of the cable is susceptible to moisture, and the insulation resistance is reduced. problems, to achieve the effect of safe and reliable use, good fire prevention effect and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

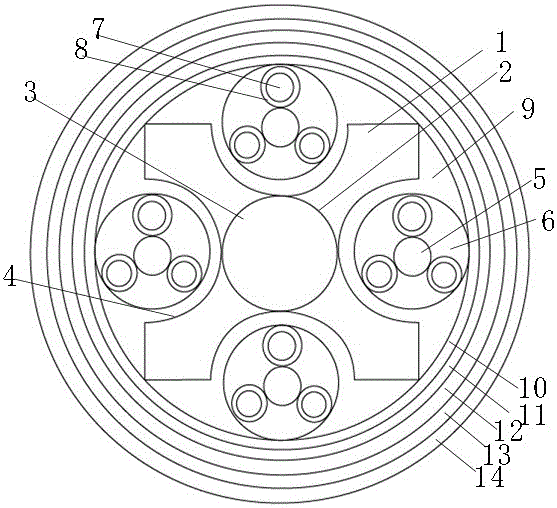

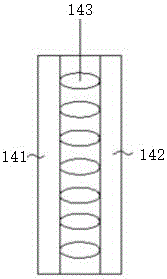

[0018] Such as figure 1 As shown, a low-voltage power cable of 0.6 / 1kv and below according to the present invention includes a cable core composed of a rectangular support frame 1 located in the center of the cable, a ground wire 3 and four main cores. There is a fiber filling layer 9 at the center, and an EPDM insulation layer 10, a calcined mica tape wrapping layer 11, a steel tape armor layer 12, a chlorosulfonated polyethylene outer sheath 13, and an elastic buffer are arranged in sequence outside the cable core. Layer 14; wherein, the center of the rectangular support frame is provided with a round hole 2, and the four sides are respectively provided with concave semicircular grooves 4 of the same size; the ground wire 3 is correspondingly placed in the round hole 2, four The first main wire core is placed in four semicircular grooves 4; wherein, the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com