A pulse metallized polypropylene film capacitor

A technology of polypropylene film and polypropylene film, which is applied in the direction of film/thick film capacitors, capacitors, laminated capacitors, etc., can solve the problem of lack of anti-oxidation, anti-aging air absorption and water absorption performance, limited discharge current impact ability, and heavy Problems such as the operation of the lower capacitor, to achieve the effects of small loss, improved explosion-proof performance, and low square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

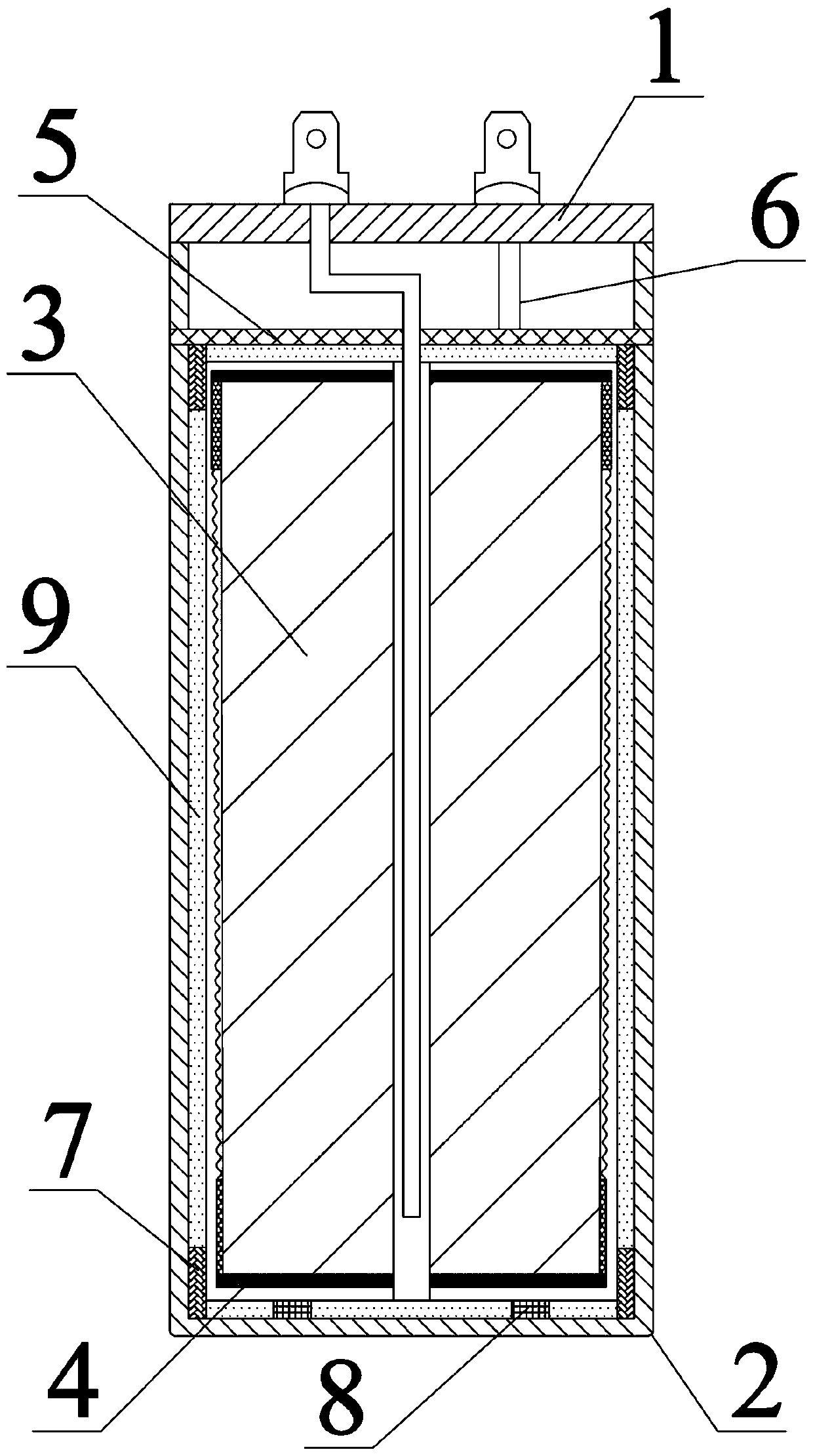

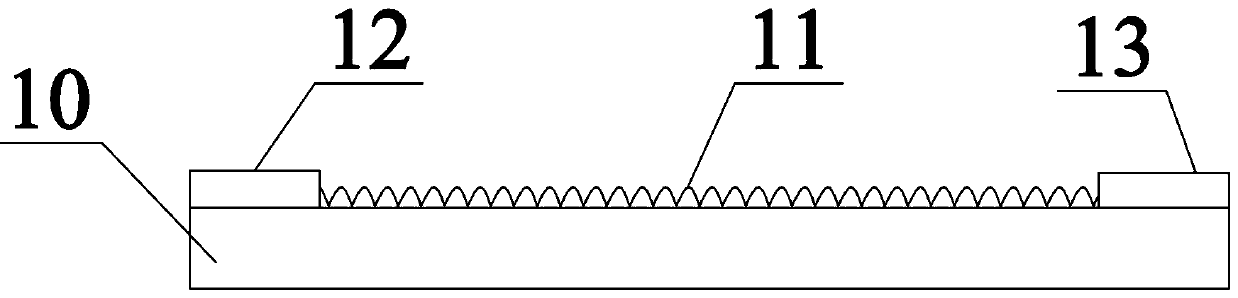

[0024] Such as figure 1 with 2 As shown, a pulse metallized polypropylene film capacitor includes a metal cylinder, a capacitor core 3, a gold-sprayed layer 4, an upper insulating cover 1 and a lower insulating cover 2, the capacitor core 3 is arranged in the metal cylinder, and the capacitor core 3 The top and the bottom are provided with a gold-sprayed layer 4, and the polypropylene film 10 is electrically connected to the gold-sprayed layer 4, and the polypropylene film 10 and the gold-sprayed layer 4 have equipotentials, thereby ensuring that the capacitor forms a current path for normal operation.

[0025] The upper insulating cover 1 and the lower insulating cover 2 are fixedly connected through the explosion-proof plate 5, and the plastic case cover used by the capacitor and the upper insulating cover 1 can be formed by integral injection molding, which has high insulation strength and is safe and reliable. The upper insulating cover 1 and the lower insulating cover 2 ...

Embodiment 2

[0035] The structure of embodiment 2 is roughly the same as that of embodiment 1, the difference is:

[0036] Among them, the impregnating agent 9 is made of the following raw materials in parts by weight: 70 parts of polyisobutylene with a molecular weight of 500-1000 and a terminal α-olefin structure content of 75%-80%, 4 parts of butylated hydroxytoluene, and 1.5 parts of refined rapeseed oil. parts, 3 parts of diatomaceous earth, 1.4 parts of additives, 1.2 parts of tricresyl phosphate, and 0.3 parts of silane coupling agent.

[0037] The auxiliary agent includes carbon black and calcium silicate, and the weight ratio of carbon black and calcium silicate is 1: 3.

[0038] The preparation method of impregnating agent comprises the following steps:

[0039] 1) Dissolve tricresyl phosphate and silane coupling agent in refined rapeseed oil, ultrasonicate at 650W for 40 minutes, then add butylated hydroxytoluene and diatomaceous earth, and stir at 650 rpm in a high-speed dispe...

Embodiment 3

[0043] The structure of embodiment 3 is roughly the same as that of embodiment 1, the difference is:

[0044] Among them, the impregnating agent 9 is made of the following raw materials in parts by weight: 65 parts of polyisobutylene with a molecular weight of 500-1000 and a terminal α-olefin structure content of 75%-80%, 2 parts of butylated hydroxytoluene, and 1.5 parts of refined rapeseed oil. 2 parts, 2 parts of diatomaceous earth, 1.2 parts of additives, 0.8 parts of tricresyl phosphate, and 0.2 parts of silane coupling agent.

[0045] The additives include carbon black and calcium silicate, and the weight ratio of carbon black and calcium silicate is 1:2.5.

[0046] The preparation method of impregnating agent comprises the following steps:

[0047] 1) Dissolve tricresyl phosphate and silane coupling agent in refined rapeseed oil, ultrasonicate at 700W for 40 minutes, then add butylated hydroxytoluene and diatomaceous earth, and stir at 650 rpm in a high-speed disperser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com