Weeding robot with both functions of targeted quantitative spraying and mechanical fixed point shoveling

A robot and mechanical technology, which is applied in the field of intelligent weeding robots, can solve problems such as inconvenient transportation, food pesticide residues, and unfavorable health, and achieve the effect of facilitating machine transportation and maintaining platform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

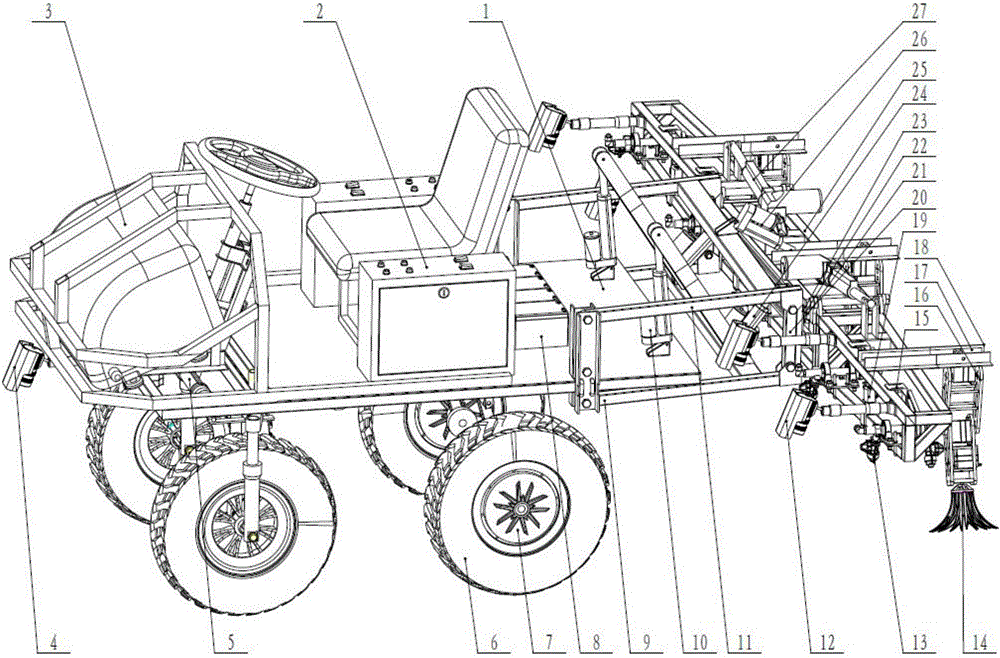

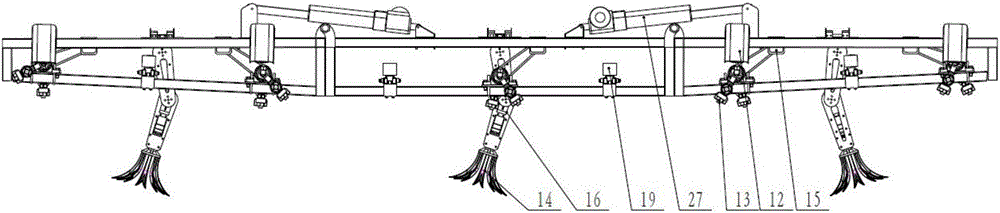

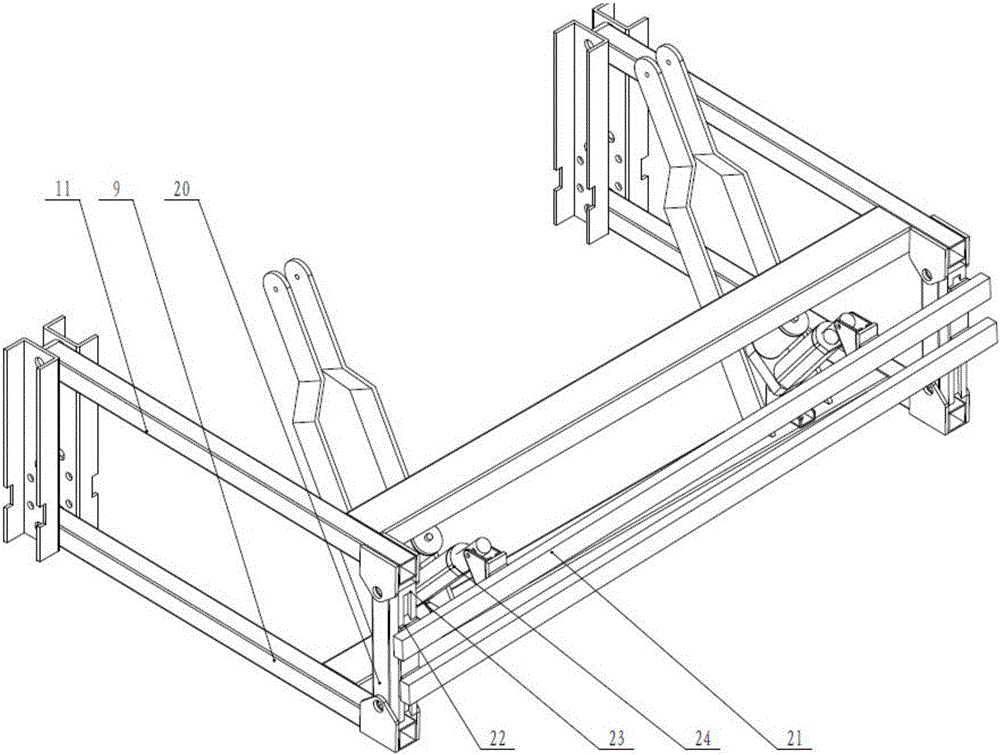

[0021] Such as figure 1 As shown, a weeding robot with the functions of targeted quantitative spraying and mechanical fixed-point shoveling. The robot is composed of a double-hub electric drive mechanical platform, a machine vision system, an intelligent control Weeding platform, alternate targeted quantitative spraying system, electric auxiliary system, feedback system; including mechanical platform (1) and intelligent control system (2) configured on the mechanical platform (1), the front end of the mechanical platform (1) The medicine tank (3) fixed by the bracket, the front end of the mechanical platform (1) is fixed by an adjustable bracket, the path acquisition camera (4) is connected with the intelligent control system (2), the front middle part of the mechanical platform (1) is fixed autonomously The steering mechanism (5), the driving device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com