A general-purpose preparative two-dimensional liquid chromatography device and its operating method

A technology of two-dimensional liquid chromatography and operation method, which is applied in the field of purification and purification of analytical chemical standard products, and achieves the effects of convenient operation, wide application range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

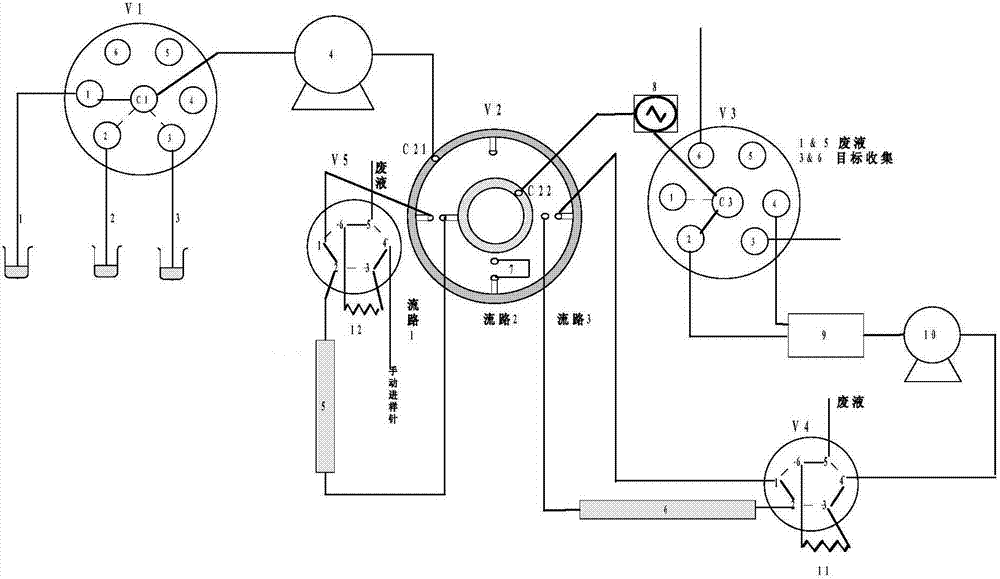

[0032] according to figure 1 The shown device structure connects each component to obtain the general preparative liquid chromatography device of the present invention:

[0033] The interface ① of the six-way multi-position valve a is connected to solvent bottle a, the interface ② is connected to solvent bottle b, and the interface ③ is connected to solvent bottle c; the inlet of the constant flow pump is connected to the common outlet in the middle of the six-way multi-position valve a, and the outlet and the flow path are selected The common inlet C21 of the multi-position valve is connected; flow path selection The multi-position valve has 4 different flow paths, flow path 1 is connected to the first-dimensional chromatographic system, and is connected to the manual six-way sampling valve b and the normal phase chromatographic column successively from the inlet end , and then connected to the outlet port, the flow path 3 is connected to the second-dimensional chromatographi...

Embodiment 2

[0040] One-dimensional normal phase separation: target to be purified: 15mg / mL caffeine in dichloromethane solution.

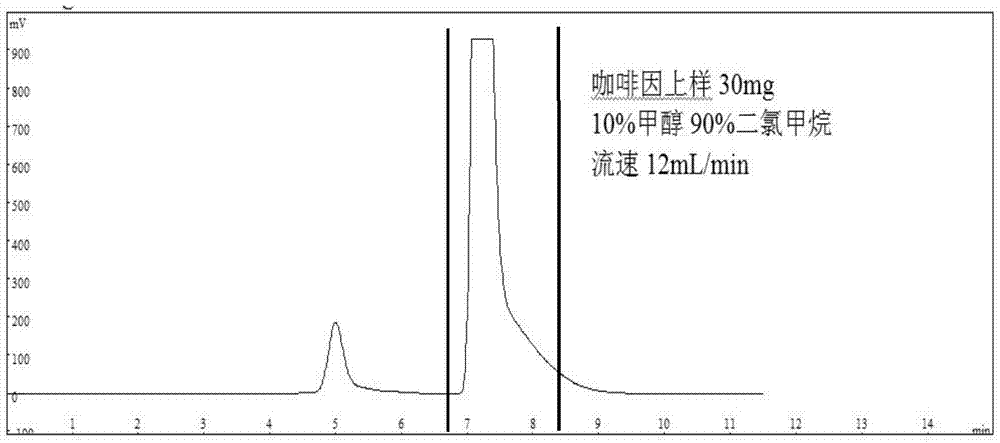

[0041] The six-way multi-position valve a is connected to the normal phase solvent (methanol 10%: dichloromethane 90%), the flow path is connected to the No. 1 flow path of the multi-position valve, and the sample is injected into the normal phase chromatogram through the six-way multi-position valve b The column (20*250mm high-efficiency silica gel column) is used for separation, the flow rate is 12mL / min; the injection volume is 2mL, the waste liquid is discharged through the interface ① of the six-way multi-position valve c, and the target components are collected through the interface ③, the target collection interval: 6.80- 8.25min. The actual separation situation is as follows figure 2 Shown: Trace impurities in caffeine are separated, and a 30mg sample can be purified in one injection. The operation is automatically executed by the self-compiled contr...

Embodiment 3

[0043] One-dimensional reversed-phase separation: target substance to be purified: 5 mg / mL capsaicin in methanol solution.

[0044] The six-way multi-position valve a is connected to 55% acetonitrile, and the flow path selection multi-position valve No. 3 is connected to the flow path. The sample is placed in the automatic sample concentration pool, and the sample passes through the automatic metering pump composed of a low-pressure metering pump and six-way multi-position valve d. The sampling device is separated on the second-dimensional reverse-phase chromatographic column (20*250mm high-efficiency C18 column), the flow rate is 16mL / min; the injection volume is 8mL. The waste liquid is discharged through the interface ⑤ of the six-way multi-position valve c, and the target components are collected through the interface ⑥. The target collection interval: 10.50-14.00min. The operation is automatically executed by the self-programmed control software. In the sample loading sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com