Automatic riveting and pressing equipment for disk chip assemblies

A disc and riveting technology, applied in the direction of safety equipment, metal processing equipment, feeding devices, etc., can solve the problems of backward production methods, large noise pollution, low production efficiency, etc., and achieve improved working environment, low noise pollution, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

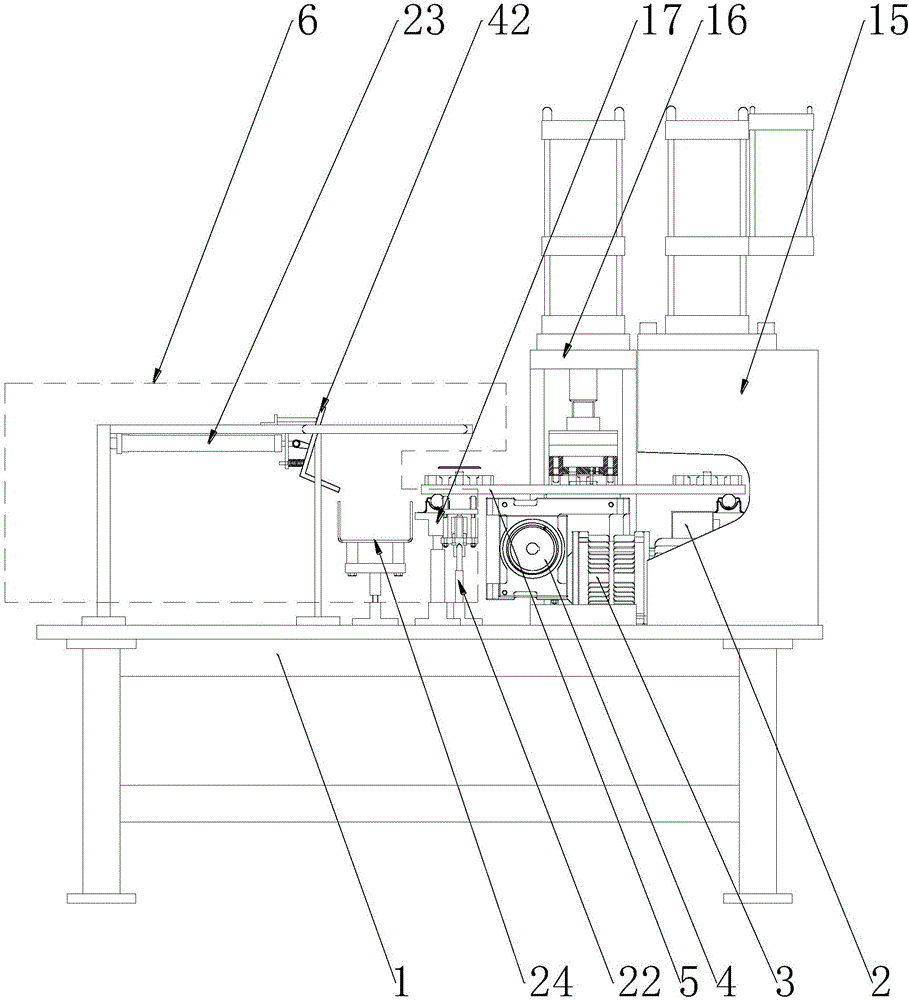

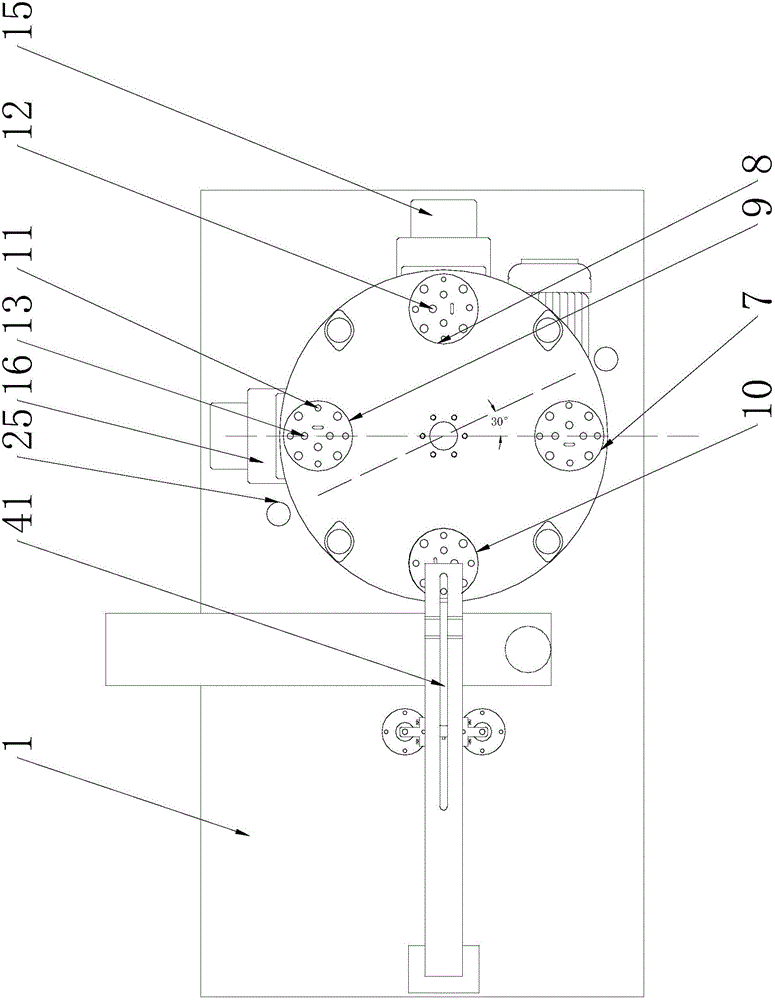

[0026] Below in conjunction with accompanying drawing, the present invention is further described:

[0027] An automatic riveting equipment for disc chip assembly, comprising a machine 1, on which a stepping motor 2, a clutch, a brake, a turbine reducer 3, a splitter 4, a rotary table 5, Disc station, press and unloading mechanism 6, the stepper motor 2 is connected to the splitter 4 through the clutch, brake, worm gear reducer 3, and the top of the splitter 4 is fixedly equipped with a disc tool. A rotary worktable 5 in the position, a press is provided on one side of the rotary worktable 5, and the unloading mechanism 6 is provided on the other side.

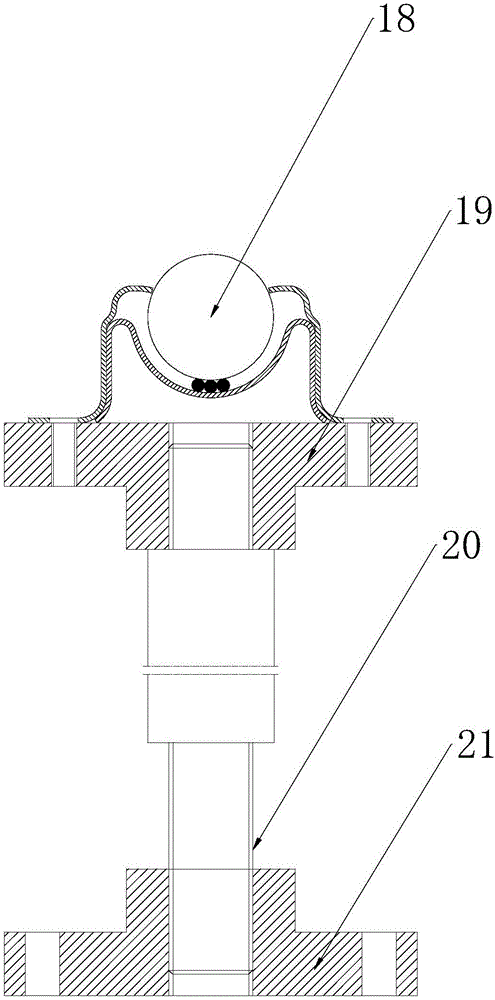

[0028] The quantity of described disk station is four, is centered on the center of circle of rotary table 5, is evenly distributed on the rotary table 5, is respectively feeding disk station 7, crouching disk station 8, riveting Pressing disc station 9 and unloading disc station 10, the structure of the loading disc station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com