A kind of non-woven fabric used for magnesium-based self-heating food heating agent and its preparation method

A heating agent and non-woven technology, which is used in food heating containers, packaging food, heat exchange materials, etc., can solve the problems of low calorific value, slow reaction, poor hygienic performance of the heated object, etc., to shorten the heating time, The effect of increasing the reaction rate and improving the hygienic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 10.2g of magnesium powder and 1.2g of iron powder were added by mechanical ball milling method for mechanical ball milling to obtain magnesium-iron alloy particles, and then 0.6g of NaCl was added to prepare heating agent.

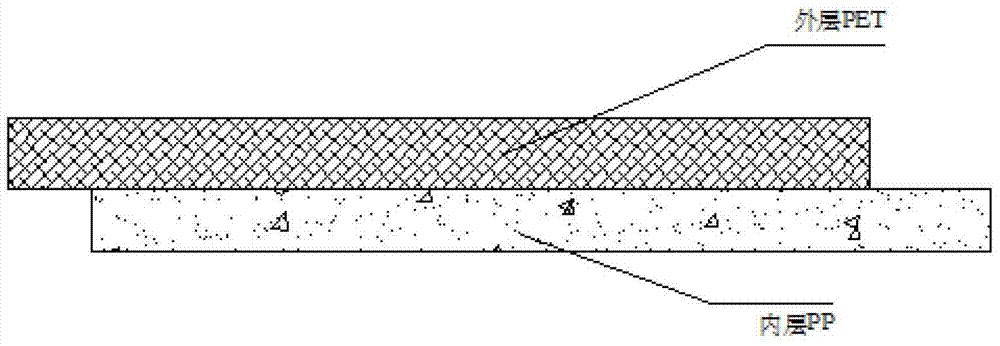

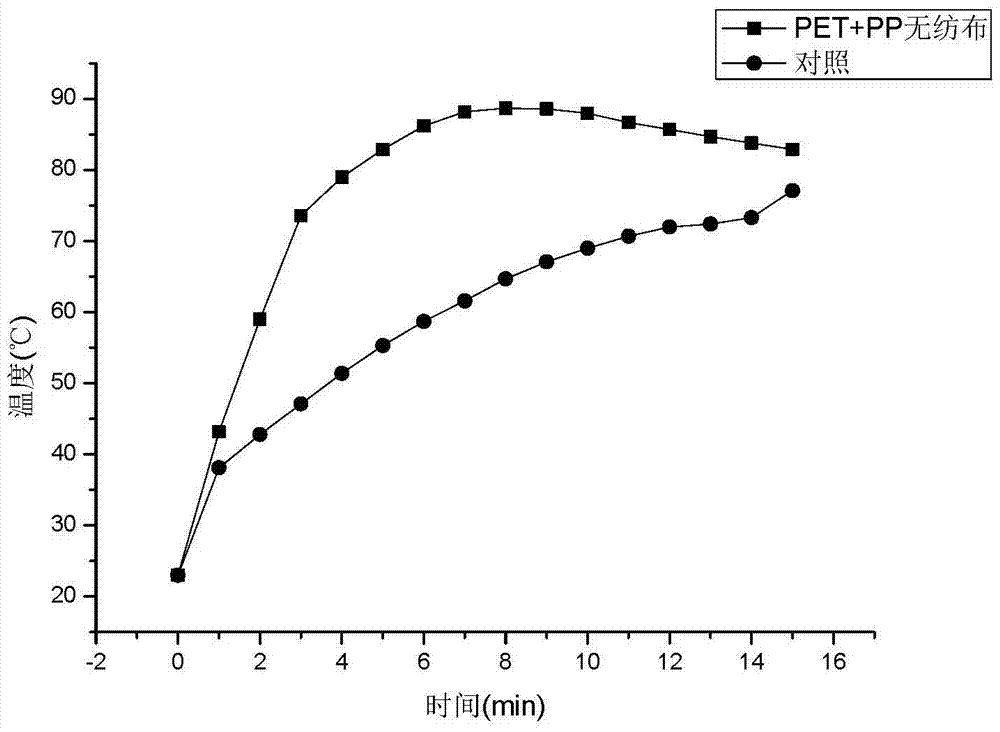

[0037] Take the non-woven fabric used for magnesium-based self-heating food heating agent, the outer layer is PET, the inner layer is PP, and the square gram weight of the outer layer PET is 45g / m 2 , the thickness is 0.25mm, the air permeability is 2500mm / s, the transverse tensile strength is 330N / 5cm, the longitudinal tensile strength is 220N / 5cm; the square gram weight of PP non-woven fabric is 10g / m 2 , with a thickness of 0.1mm and an air permeability of 8000mm / s. The non-woven fabric used for the magnesium-based self-heating food heating agent is made into a non-woven bag with a size of 10*15cm and a quadruple package. Add 3g of magnesium-based self-heating food heating agent to make a self-heating food heating agent bag, put the self-heating ...

Embodiment 2

[0040] 10.2g of magnesium powder and 1.2g of iron powder were added by mechanical ball milling method for mechanical ball milling to obtain magnesium-iron alloy particles, and then 0.6g of NaCl was added to prepare heating agent.

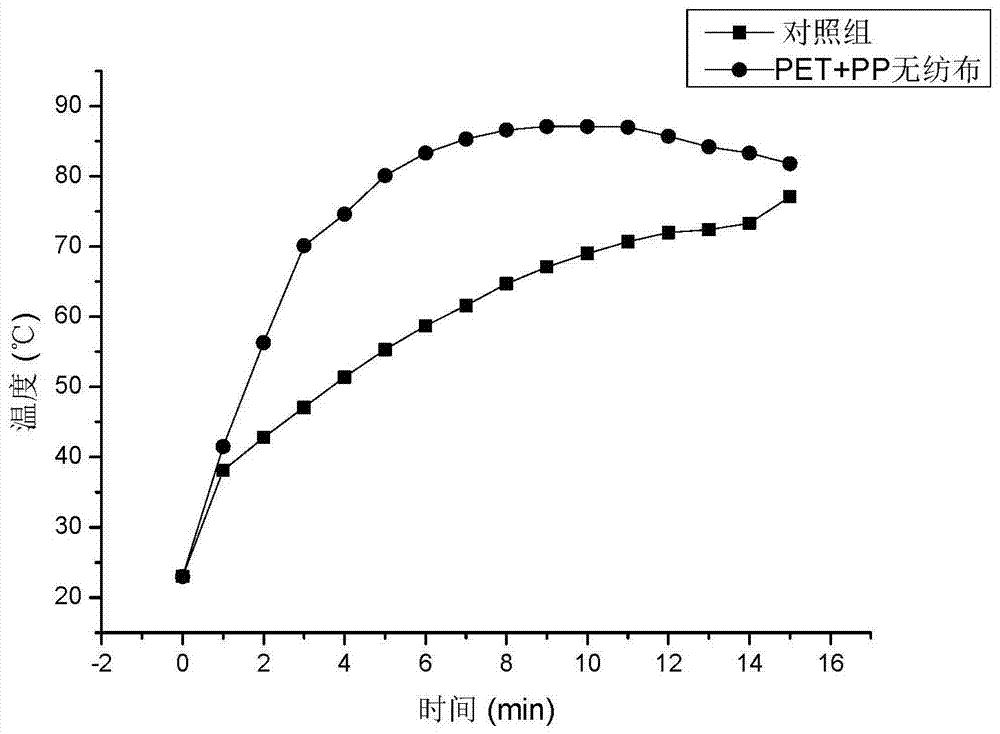

[0041] Take the non-woven fabric used for magnesium-based self-heating food heating agent, the outer layer is PET, the inner layer is PP, and the square gram weight of the outer layer PET is 55g / m 2 , the thickness is 0.34mm, the air permeability is 2300mm / s, the transverse tensile strength is 340N / 5cm, the longitudinal tensile strength is 240N / 5cm; the square gram weight of PP non-woven fabric is 10g / m 2, with a thickness of 0.1mm and an air permeability of 8000mm / s. The non-woven fabric used for the magnesium-based self-heating food heating agent is made into a non-woven bag with a size of 10*15cm and a quadruple package. Add 3g of self-heating food heating agent to make a self-heating food heating agent bag, put the heating agent bag into the hea...

Embodiment 3

[0044] 10.2g of magnesium powder and 1.2g of iron powder were added by mechanical ball milling method for mechanical ball milling to obtain magnesium-iron alloy particles, and then 0.6g of NaCl was added to prepare heating agent.

[0045] Take the non-woven fabric used for magnesium-based self-heating food heating agent, the outer layer is PET layer, the inner layer is PP layer, the square gram weight is 75g / m 2 , the air permeability is 1900mm / s, the thickness is 0.5mm, the transverse tensile strength is 350N / 5cm, and the longitudinal tensile strength is 250N / 5cm. The non-woven fabric used for magnesium self-heating food heating agent is made into a size of 10 *15cm, quadruple non-woven bag, put 3g of self-heating food heating agent into each bag opening to make a self-heating food heating agent bag, put the heating agent bag into the heating bag to heat a 240g water bag , Add 30ml of water to the heating bag to initiate the reaction, and record the temperature every 1min. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com