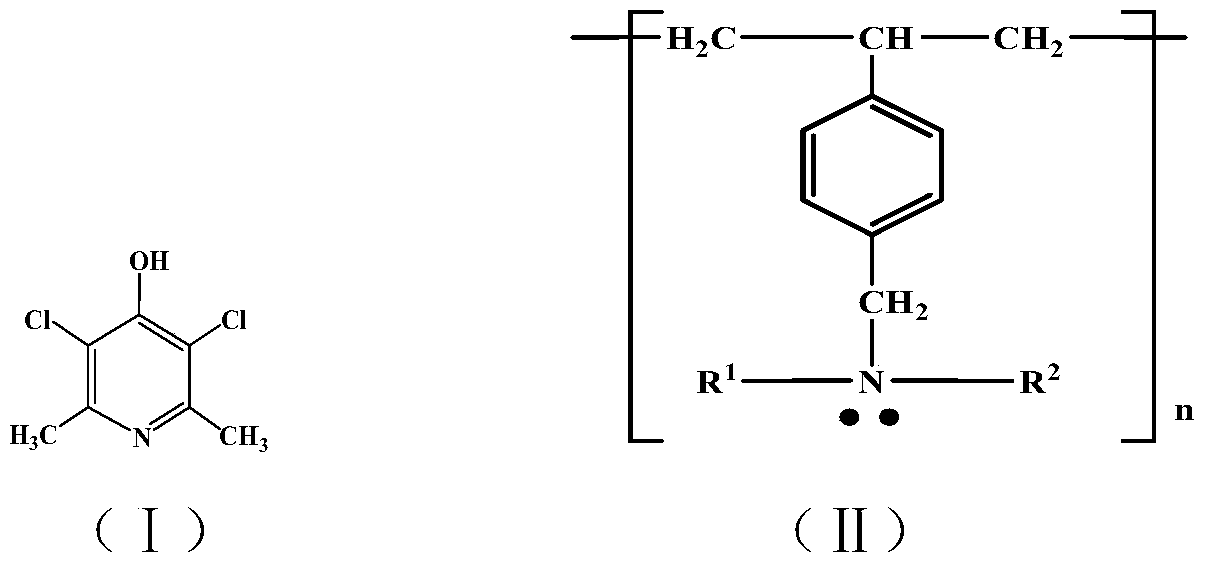

A kind of preparation method of 2,6-dimethyl-3,5-dichloro-4-hydroxypyridine

A technology of hydroxypyridine and dimethyl, which is applied in the field of preparation of 2,6-dimethyl-3,5-dichloro-4-hydroxypyridine, can solve the problems of preparation method pollution and achieve simple separation and purification Effects of unit reactions, ease of manipulation, and postprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

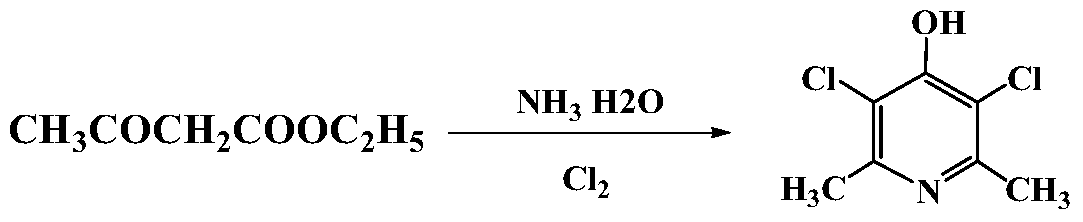

Method used

Image

Examples

Embodiment 1

[0019] In a 500 ml three-necked flask, add 130 g (1 mole) of ethyl acetoacetate, 39 g of Styrene-DVB (D301R) resin, react at 60°C for 3 hours, add 100 ml of distilled water, and feed 51 g of ammonia gas under stirring (3 moles), after reacting at 30°C for 5 hours, feed 142 grams (2 moles) of chlorine gas under stirring, react at 30°C for 2 hours, filter, filter out Styrene-DVB (D301R) resin and solids, use for filter cake After washing with 100 ml of NaOH (mass concentration 10%) aqueous solution, the Styrene-DVB (D301R) resin can be recycled. A small amount of ethanol was distilled off from the filtrate, and the crystals were precipitated after standing, filtered, and dried to obtain 87.4 g of the target product, with a yield of 91%. Melting point: 265-268°C. HRMS (ESI): m / e=192 (M + ).

Embodiment 2

[0021] In a 500 ml three-necked flask, add 130 g (1 mole) of ethyl acetoacetate, 39 g of Styrene-DVB (D301T) resin, react at 30°C for 5 hours, add 100 ml of distilled water, and feed 85 g of ammonia gas under stirring (5 moles), after reacting for 2 hours at 10 DEG C, feed 142 grams (2 moles) of chlorine gas under stirring, react for 2 hours at 30 DEG C, filter out Styrene-DVB (D301T) resin and solid, filter cake with NaOH ( The Styrene-DVB (D301T) resin can be recycled after washing with 100 milliliters of an aqueous solution with a mass concentration of 10%. A small amount of ethanol was distilled off from the filtrate, and the crystals were precipitated after standing, filtered, and dried to obtain 87.8 g of the target product, with a yield of 91.5%. Melting point: 265-268°C. HRMS (ESI): m / e=192 (M + ).

Embodiment 3

[0023] In a 500 ml three-necked flask, add 130 grams (1 mole) of ethyl acetoacetate, 39 grams of Styrene-DVB (D301G) resin, react at 60 ° C for 3 hours, add 100 ml of distilled water, and feed 34 grams of ammonia gas under stirring (2 moles), after reacting at 30 DEG C for 5 hours, feed 71 grams (1 moles) of chlorine gas under stirring, react at 10 DEG C for 1 hour, filter out Styrene-DVB (D301G) resin and solid, filter cake with NaOH ( After washing with 100 milliliters of an aqueous solution with a mass concentration of 10%, the Styrene-DVB (D301G) resin can be recycled. A small amount of ethanol was distilled off from the filtrate, and crystals were precipitated after standing, filtered, and dried to obtain 87.0 g of the target product, with a yield of 90.6%. Melting point: 265-268°C. HRMS (ESI): m / e=192 (M + ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com