Polysaccharide polymer water plugging gel

A polysaccharide polymer, hydrogel technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of small applicable temperature range and pollute the environment, and achieve the effect of wide temperature applicable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

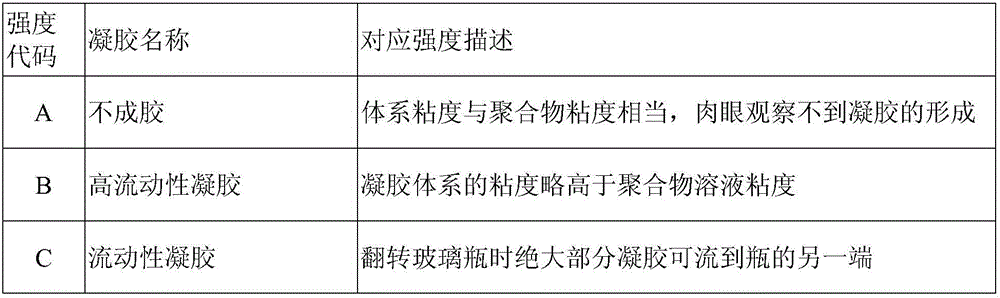

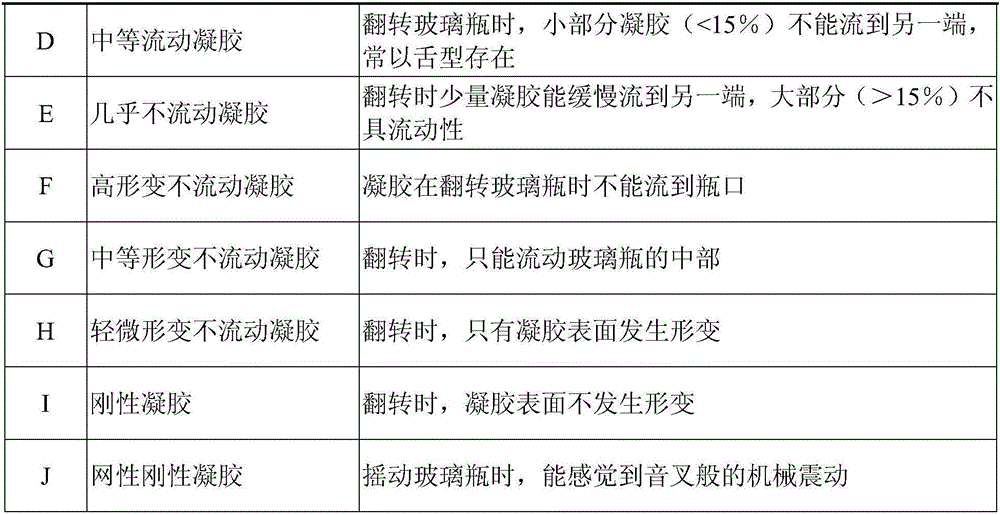

[0035] According to the polysaccharide main agent chitosan 5%, the crosslinking agent (N, N-methylenebisacrylamide) 2%, the cosolvent (acetic acid) 3%, the concentration range of the gelation regulator (sodium chloride) is 0 ~10%, the rest is water components to configure the water blocking gel system and put into the oven. The experimental temperature is 130°C, and the gelation time is between 6 and 12 hours. The gelation conditions are shown in Table 2. As shown in Table 2, the final setting strength can reach grade I, and no syneresis occurs in 90 days.

[0036] Table 2 embodiment 1 gelation situation

[0037] Gelling Regulator Concentration (%)

Embodiment 2

[0039] According to the variation range of polysaccharide main agent chitosan concentration is 2.5~5%, cross-linking agent (polyethylene glycol (600) diacrylate 1.5%, N, N-methylenebisacrylamide 0.5%) 2%, auxiliary The solvent (hydrochloric acid) is 1%, the gel-forming regulator (sodium chloride) is 3%, and the remaining components are water to configure a water-blocking gel system and put it into an oven. The experimental temperature is 35°C, and the gelation time is between 20 and 72 hours. The gelation conditions are shown in Table 3. As shown in Table 3, the final setting strength can reach grade I, and no syneresis occurs in 90 days.

[0040] Table 3 embodiment 2 gelation situation

[0041] Concentration of polysaccharide main agent (%)

Embodiment 3

[0043] According to the polysaccharide main agent chitosan 3%, the crosslinking agent (N, N-methylene bisacrylamide) concentration variation range is 1-2%, cosolvent (acetic acid) 2%, gelation regulator (sodium chloride ) is 10%, and the rest is water components configured into a water-blocking gel system and put into an oven. The experimental temperature was 130°C, and the gelation time was between 20 and 32 hours. The gelation conditions are shown in Table 4. As shown in Table 4, the final setting strength can reach grade I, and no syneresis occurred in 90 days.

[0044] Table 4 embodiment 3 gelation situation

[0045] Cross-linking agent concentration (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com