Biomass and coal mixed combustion auxiliary device of boiler

A technology of auxiliary equipment and biomass, which is applied to combustion equipment, fluidized bed combustion equipment, and burning fuel in a molten state, etc., can solve the problems of high boiler manufacturing cost, high engineering cost, import of auxiliary equipment, etc., so as to improve high-efficiency combustion. , the effect of reducing emissions and optimizing operating levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

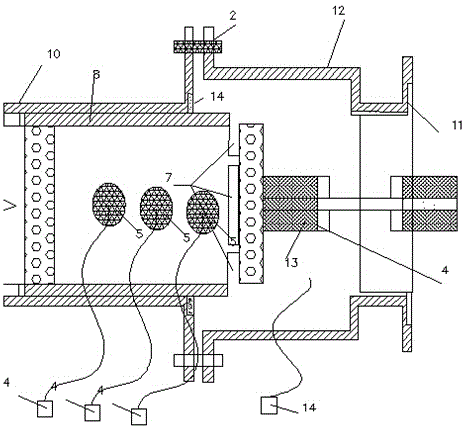

[0020] A combustion auxiliary equipment for co-combusting biomass and coal in boilers, including CFB test bench 1, circulating fluidized bed boiler 2, high-precision thermogravimetry 3, distribution fan 4, batching machine 5, nitrogen oxide generator 6, The biomass ash collector 7 is characterized in that: one end of the high-precision thermogravimetric system 3 is fixedly connected to the distribution fan 4 and the other end is fixedly connected to the circulating fluidized bed boiler 2, and the CFB test bench 1 is controlled by a digital display. The line is connected with key parts such as circulating fluidized bed boiler 2, high-precision thermogravimetric system 3, distribution fan 4, batching machine 5, nitrogen oxide generator 6, biomass ash collector 7, and the batching machine 5 is open at one end , can be arranged in the shape of a bucket or a trough, and the biomass ash collector 7 is arranged at the bottom of the device and is made of mesh-shaped high-temperature-re...

Embodiment 2

[0022] Example 2 as figure 1 As shown, it is improved on the basis of Example 1, and its high-precision thermogravimetric 3 when the temperature rises, impels potassium and chlorine to release from the biomass organic matrix combination, and transfers to the liquid tar phase, and more than half of the chlorine For further release, it is put into the gas phase in the form of HCI.

Embodiment 3

[0024] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1, the air inlet of its nitrogen oxide generator 6 filter is connected with the gas source, and its output is connected to the nitric oxide generator through the air pump connected to it through the gas delivery pipe Connected, and connected to the nitrogen oxide proportional regulator through the output pipe of the nitric oxide generator and the flow meter connected thereto; finally output through the nitrogen oxide proportional regulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com