A device and method for producing high-purity nitrogen and low-purity oxygen

A low-purity, high-purity technology, applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction, etc., can solve problems such as energy waste, achieve the effect of reducing production costs, reducing repeated construction and investment, and objective economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

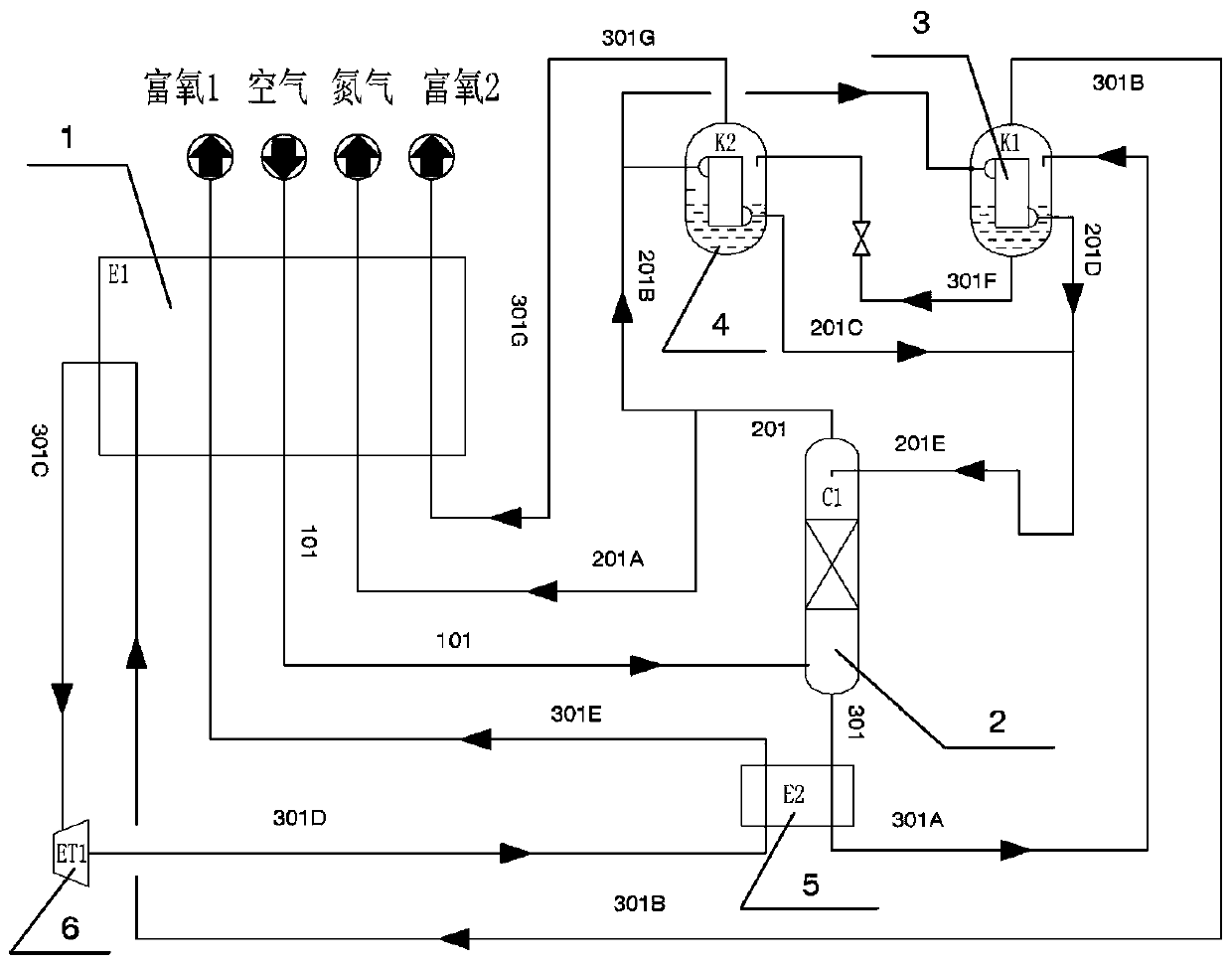

[0034] See attached figure 1 , the present invention produces the device of high-purity nitrogen and low-purity oxygen, comprises 1 main heat exchanger E1, 2 rectifying tower C1, 3 condenser K1, 4 condenser K2, 5 subcooler E2 and 6 turbo expanders ET1, each device is connected through pipelines, and the connection relationship is:

[0035] The air inlet of the main heat exchanger E1 is the input port of filtered and purified air, and its air outlet communicates with the air inlet at the lower part of the rectification tower C1 through the 101 pipeline; the high-purity nitrogen outlet at the top of the rectification tower C1 passes through The 201 pipeline is divided into two parts and enters the 201A pipeline and the 201B pipeline respectively. The 201A pipeline is connected with the high-purity nitrogen inlet of the main heat exchanger E1, and the high-purity nitrogen is discharged and collected from the main heat exchanger E1 outlet; the 201B pipeline is respectively connect...

Embodiment 2

[0040] See attached figure 1 , the present invention utilizes the device described in embodiment 1 to produce the method for high-purity nitrogen and low-purity oxygen, the detailed steps of this method are as follows:

[0041] a. The air from the atmosphere is firstly compressed, then filtered and purified by conventional methods to remove moisture and carbon dioxide in the air; the purified air enters the main heat exchanger E1 for cooling down to -170°C;

[0042] b. The air cooled by the main heat exchanger E1 in step a enters the rectification tower C1 from the lower part of the rectification tower C1 through the 101 pipeline (the rectification tower adopts a plate rectification tower) for rectification and separation, and after separation, the rectification tower C1 High-purity nitrogen is obtained at the top (the purity of high-purity nitrogen is ≥99.9995%), and oxygen-enriched liquid air is obtained at the bottom; among the obtained high-purity nitrogen, the high-purity...

Embodiment 3

[0045] Embodiment 3: basically the same as Embodiment 2, the difference is:

[0046] In step c: the oxygen-enriched liquid air is evaporated in K1 with an evaporation rate of 50%; the oxygen-enriched gas product 1 is obtained (the product has a purity of 24.9% and a pressure of 11KPa);

[0047] In step d: the oxygen-enriched gas product 2 is obtained, the purity of the obtained oxygen-enriched gas product 2 reaches 47%, and the pressure p reaches 0.23 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com