Lead magnesium niobate and lead titanate monocrystalline-based semiconductor ferroelectric field effect heterostructure, manufacture method therefor and application thereof

A technology of lead magnesium niobate titanate and electric field effect, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc. It can solve the problems of film performance deterioration, harsh film deposition conditions, composition segregation, etc., and simplify the preparation process and preparation, excellent ferroelectric field effect characteristics, and the effect of changing electrical transport properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

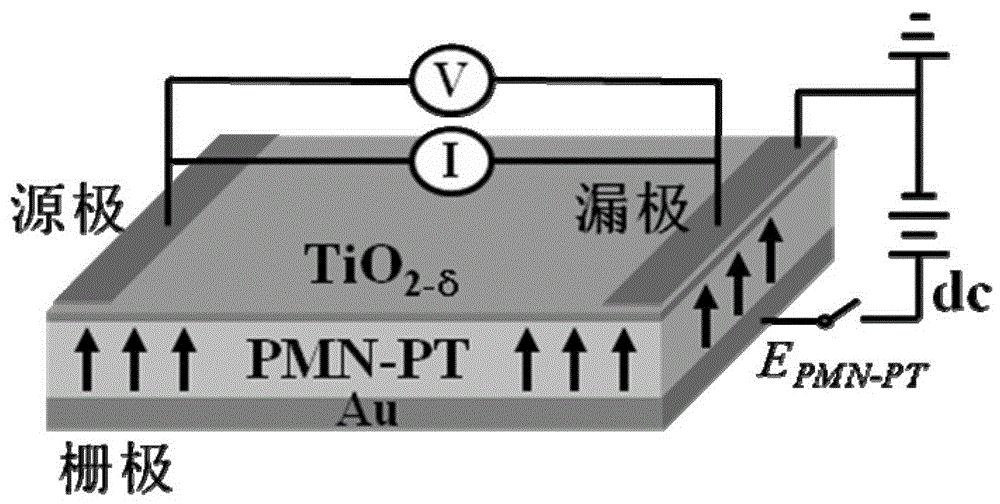

[0025] The semiconductor ferroelectric field effect heterostructure based on lead magnesium niobate titanate single crystal provided by the present invention includes a substrate (gate) using lead magnesium niobate titanate lead ferroelectric single crystal as the substrate (gate) to be formed on the substrate The titanium dioxide semiconductor film on the bottom is used as the channel (conductive channel) and the gold electrodes are distributed on one side of the lead magnesium niobate titanate single crystal substrate and the titanium dioxide semiconductor film side by evaporation or other methods. (or silver electrodes, or other electrodes). Wherein, the thickness of the lead ferroelectric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com